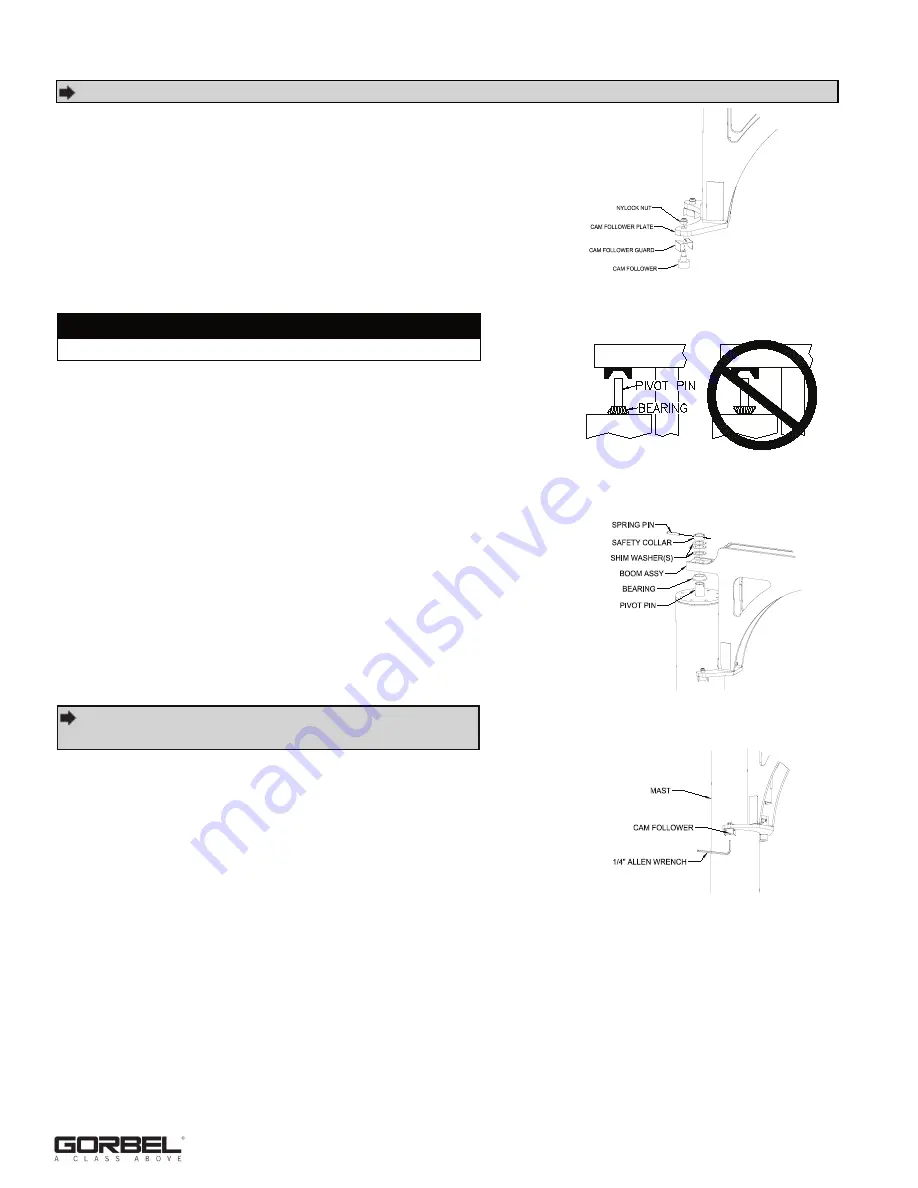

STEP 4 - PIVOT PRO® (FREE STANDING) BOOM INSTALLATION

4.1

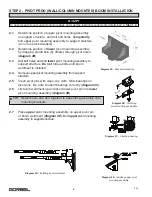

Install cam followers onto cam follower plate at bottom

of boom assembly (

diagram 4A

).

Position and align cam guards as shown making sure

they do not protrude past inside edge of cam follower

plate. Tighten nylock nuts until snug. Nuts will need

to be tightened to 30 ft-lbs after eccentric cam follower

is best oriented to prevent boom drift, see Step

4.4

.

4.2

Place and orient pivot bearing on mast pivot pin

(

diagram 4B

).

4.3

Place boom assembly over pivot pin on mast. Fold

secondary arm so that it is close to mast. Stack shim

washer(s) and safety collar on pivot pin (

diagram 4C

).

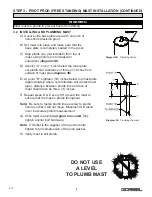

(3) 0.048” thick and (1) 0.075” thick shim washers are

supplied. Use one or more of these washers as required

to minimize the gap between the boom assembly and the

safety collar. The safety collar pin hole is slightly offset.

This collar may be installed in one of two ways (flipped)

to act as a 0.025” thick shim. When properly shimmed,

the holes on safety collar and pivot pin will be aligned.

Using hammer, tap spring pin until it protrudes equally

from either side of safety collar.

4.4

Level boom by evenly adjusting eccentric cam followers

with an allen wrench (

diagram 4D

). Once leveled,

tighten nylock nuts to 30 ft-lbs.

4.5

Check to make sure that both rollers have full face

contact with mast pipe.

Carefully swing boom through entire travel to ensure

boom is clear of obstructions and does not drift.

If boom drifts

, make sure that cam followers are

evenly adjusted and/or mast is plumb.

TIP:

Unloaded boom will tilt slightly upward.

WARNING

If nylock nut is removed, it must be replaced.

Diagram 4A.

Installing cam followers.

Diagram 4B.

Orienting bearing.

Diagram 4C.

Installing boom weldment.

Diagram 4D.

Adjusting eccentric

cam followers.

10

9/18

TIP:

Retain boom and arm together to ease

lifting assembly onto mounting brackets.