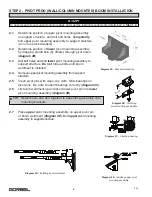

STEP 2 - PIVOT PRO® (WALL/COLUMN MOUNTED) BOOM INSTALLATION

2.1

Determine position of upper pivot mounting assembly

on support structure, and drill bolt holes.

Temporarily

bolt upper pivot mounting assembly to support structure

(do not use lock washers).

2.2

Determine position of

lower

pivot mounting assembly

by dropping plumb bob (by others) through pivot holes

(

diagram 2B

).

2.3

Drill bolt holes and bolt

lower

pivot mounting assembly to

support structure.

Do not

torque bolts until boom

weldment is installed.

2.4

Remove upper pivot mounting assembly from support

structure.

2.5

Clean pivot pins with clean, dry cloth. Slide bearings on

pivot pins. Be sure to orient bearings correctly (

diagram 2C

).

2.6

Lift boom weldment up and insert lower pivot pin into

lower

pivot mounting assembly (

diagram 2D

).

2.7

Place

upper

pivot mounting assembly on upper pivot pin

of boom weldment (

diagram 2E

). Bolt

upper

pivot mounting

assembly to support structure.

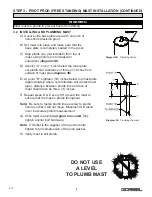

STOP!

Do not proceed if your support structure does not meet the loading requirements determined in

Step 1.4

.

Diagram 2B.

Plumbing

pivot mounting assemblies

.

Diagram 2C.

Orienting bearing.

Diagram 2D.

Installing boom weldment.

Diagram 2E.

Installing upper pivot

mounting assembly.

6

9/18

TIP:

Retain boom and arm together to ease lifting assembly onto

mounting brackets.

27.45”

Diagram 2A.

Bracket dimensions