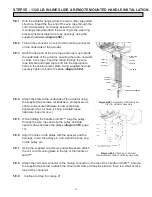

STEP 4 - COIL CORD INSTALLATION

Note:

G-Force® units, standard in-line or remote mounted, that are ordered from the

factory will be shipped with the coil cord assembled to the actuator wear ring and the

coil cord footer, creating the coil cord assembly (

diagrams 4A

and

4B

). In addition,

units ordered with air power will have a 1/4” ID nycoil air hose coil cord assembled

onto the coil cord assembly (not shown).

4.1

Verify the coil cord assembly is correct. There are two coil cord

assemblies: standard and double length. The standard coil cord assembly

is used on systems with a trolley saddle up to 14’ (4.27m) and will measure

approximately 8.3” (211.46mm) in length. The double length coil cord

assembly is used on systems with a trolley saddle greater than 14’

(4.27m) and will measure approximately 16.4” (415.93mm) in length.

4.2

Feed the wire rope from the actuator assembly through the center of the

coil cord assembly.

4.3

Use the actuator assembly hardware to fasten the coil cord assembly to

the actuator (

diagram 4C

). Adjust the coil cord in the clamps so that the

coil cord connector is conveniently located on the proper side of the

actuator assembly.

Note:

The orientation of the coil cord must be correct

so that the connector is located properly (

diagram 4DC

). There should

be no need for adjustment of the coil cord clamps if coil cord is aligned

as shown.

4.4

Thread the coil cord connector into the actuator connector (

diagram 4C

).

4.5

Assure that the coils of the coil cord are

centered around the wire rope when

properly installed.

4.6

Use the 16mm shoulder bolt and M12

jam-nut to retain the coil cord footer to the

thimble in the wire rope.

Note:

The

shoulder bolt and jam-nut will be used to

retain the handle or collector in the next

step.

4.7

If applicable, connect air hose coil cord to supply line from

the actuator assembly. The air hose coil cord is provided

with two (2) ¼” NPT male swivel fittings located at both ends of

the air hose.

Diagram 4A.

Standard Coil

Cord Assembly.

Diagram 4B.

Double

Length Coil Cord

Assembly.

4.8

For standard in-line slide handle or in-line force sensing handle

installation, go to Step 5A, page 12.

For remote mounted slide handle installation, go to Step 5B, page 12.

For suspended pendant handle installation, go to Step 5C, page 14.

For remote mounted pendant handle installation, go to Step 5D, page 15.

For 1320 lb. in-line slide or remote mounted handle installation, go to Step 5E, page 16.

For 1320 lb. suspended pendant handle installation, go to Step 5F, page 17.

For remote mounted force sensing handle installation, go to Step 5H, page 19.

For remote mounted force sensing hub handle installation, go to Step 5I, page 20.

CAUTION

The connectors on the coil cord are keyed. The connector must be

aligned correctly before it threads into place.

TIP:

This step is best completed once the actuator has been installed into the bridge system.

Diagram 4C.

Coil Cord Assembly

Installation at the Actuator (Bottom

view/black center not shown).

10