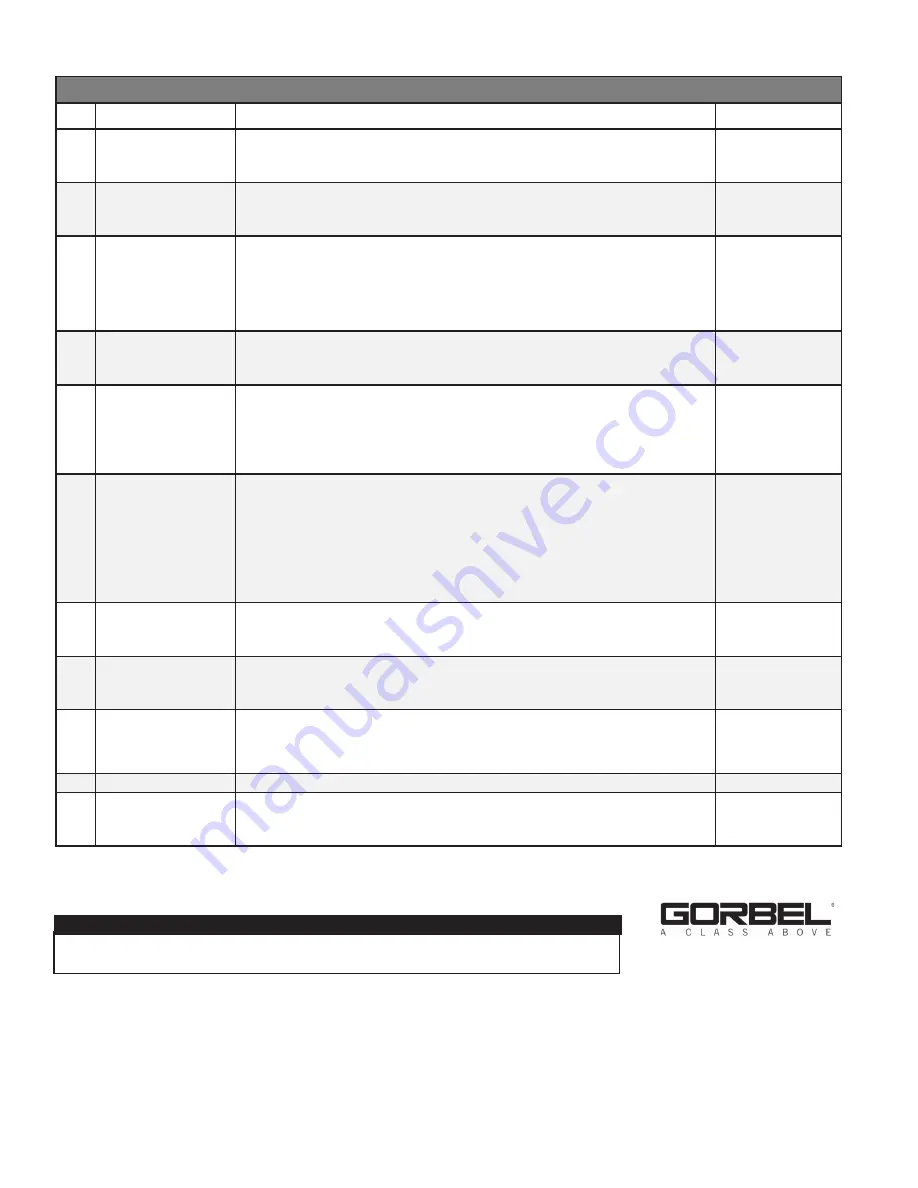

INSPECTION AND MAINTENANCE SCHEDULE

GORBEL

G-FORCE

®

INSPECTION AND MAINTENANCE SCHEDULE

ITEM

COMPONENT

MAINTENANCE

FREQUENCY*

1

Wire Rope

Look for any obvious external defects, damage or excessive wear. Check

the lower end where it attaches to the handle, swivel assembly

or tooling (by others) for signs of damage or excessive wear.

Start of

Each Shift

2

Wire Rope

Expose as much of the wire rope as possible and wipe it off with a clean

dry cloth. Use the jog button to pay out as much wire rope as

possible.

Monthly

3

Wire Rope

Maintenance listed in (1) as well as reduction of rope diameter below

nominal diameter due to loss of core support, internal or external corrosion,

or wear of outside wires; severely corroded or broken wires at end

connections; or severely corroded, cracked, bent, worn, or improperly

applied end connections.

Periodically

To be determined

by qualified

persons only

4

Coil Cord

Assembly

Look for any obvious external defects or damage caused by the wire rope

or other external causes. Make sure all coil cord clamps are in

place.

Start of

Each Shift

5

Slack Switch

Check Adjustment

Using the handle, lower the wire rope until it goes slack. There should

be no additional movement downward once it is slack. If the wire rope

continues to pay out, stop immediately and perform the slack switch

adjustment. Check the coil cord and air hose clamps on the wear ring to

ensure the wear ring is moving freely inside the actuator opening.

Initial Install &

Monthly

6

Handle

Check for smooth operation of the handle.

•

Slide Handle Only - Check operator present sensor for correct operation.

Use a gentle puff of compressed air or a soft cloth to clean the sensor. Do

not apply any pressure to the lens or do anything that may scratch it.

Verify proper handle swivel functionality.

•

Pendant Handle Only - Check levers to make sure they function

smoothly.

Start of

Each Shift

7

Handle I/O

Connections

Check connections at handle (if equipped). Wipe off any oil or other

contamination from either handle at this time. Clean the OLED screen

as well.

Monthly

8

Air Hose

(if equipped)

Look for any obvious external damage or wear caused by the wire rope or

other external causes. Make sure the air hose is secured

properly with the correct clamps

Start of

Each Shift

9

Load Hook and/or

Tooling

(by others)

Check that the load hook is secured properly to the handle or swivel.

Make sure lock washers are compressed completely and any other

associated hardware is secure.

Start of

Each Shift

10

G-Force

®

Assembly

Conduct a visual inspection of the entire G-Force® unit.

Start of Each Shift

11

Limit

Switches

Verify that the upper and lower limit switches are operating properly.

Verify that the slack switch is operating properly. Replace switches

immediately if they are faulty.

Initial Install and

Start of Each Shift

* Federal, state and local codes may require inspection and maintenance checks more often. Please check the

federal, state and local code manuals in your area.

For additional service information, please consult the G-Force® Q2 and iQ2

Series Service Manual. Contact the Gorbel® After the Sales Service group to

request a copy.

600 Fishers Run, P.O. Box 593

Fishers, NY 14453-0593

Phone: (800) 821-0086

Fax: (800) 828-1808

E-Mail: info@gorbel.com

© 2020 Gorbel Inc.

All Rights Reserved

Any changes in rotating effort or unusual noises

must be immediately identified and corrected.

WARNING

12/2020 Rev C

92