G-Force® & Easy Arm Q2 - iQ2 Service Manual

Gorbel Inc.

Revised 5/21

9 - 54

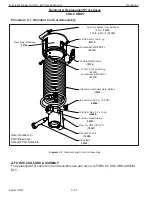

Procedure F-2A. Housing Sub-Assembly Disassembly

1. Remove the remote mount cap sub-assembly. Refer to Procedure F-1A.

2. Remove the housing sub-assembly. Refer to Procedure F-2A.

3. Remove (3) M6 socket head cap screws (SHCS) from the mount plate.

Note: Do not remove the mount plate as

it is attached via the load cell sensor cable. Rotate as little as necessary to perform the following step.

4. Remove (4) M5 socket head cap screws (SHCS) and M5

fl

atwashers.

5. Separate the handle top sub-assembly from the handle bottom. Use caution, the ribbon cable and ground wire

will still be connected.

Note: Do not put excess strain on the loadcell sensor cable until it is detached from the

motherboard by depressing the latch on the RJ45 connector.

6. All the sub-assembly internal components can be removed or replaced using the exploded view drawings as

reference.

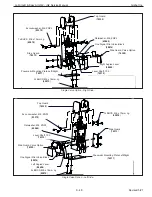

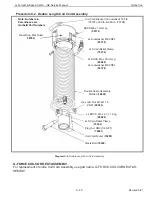

Procedure F-2B. Housing Sub-Assembly Reassembly

1. All the sub-assembly internal components can be removed or replaced using the exploded view drawings as

reference.

2. Once all the internal components have been positioned properly, slide the handle bumper in place on the handle

bottom (if removed) and join the handle top sub-assembly with the handle bottom. Make sure the ribbon cable,

loadcell sensor cable, and ground wire are connected properly.

3. Install the (4) M5 socket head cap screws (SHCS) and M5

fl

atwashers, rotating the mount plate as little as

necessary.

4. Install the (3) M6 socket head cap screws (SHCS) securing the mount plate.

5. Install the housing sub-assemblies onto the handle shaft. Refer to Procedures F-2B.

6. Install the remote cap sub-assemblies as required. Refer to Procedures F-1B.

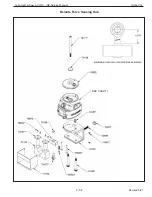

S-Handle Top Machined

(

74197

)

LCD Window

(

74223

)

2x External Snap Ring, 6mm

(

65065

)

Bumper

(

74207

)

Reworked Slide

Handle Bottom

(

74155

)

4x Lockwasher, M5, High-Collar

(

65062

)

2x Handle Pushbutton

(

74215

)

4x SHCS, M5x8-55

(

65067

)

Note: Numbers in

Parentheses are

Gorbel® Part Numbers

Diagram F-2a. Housing Sub-Assembly Assembly and Disassembly