6

9/18 Rev. F

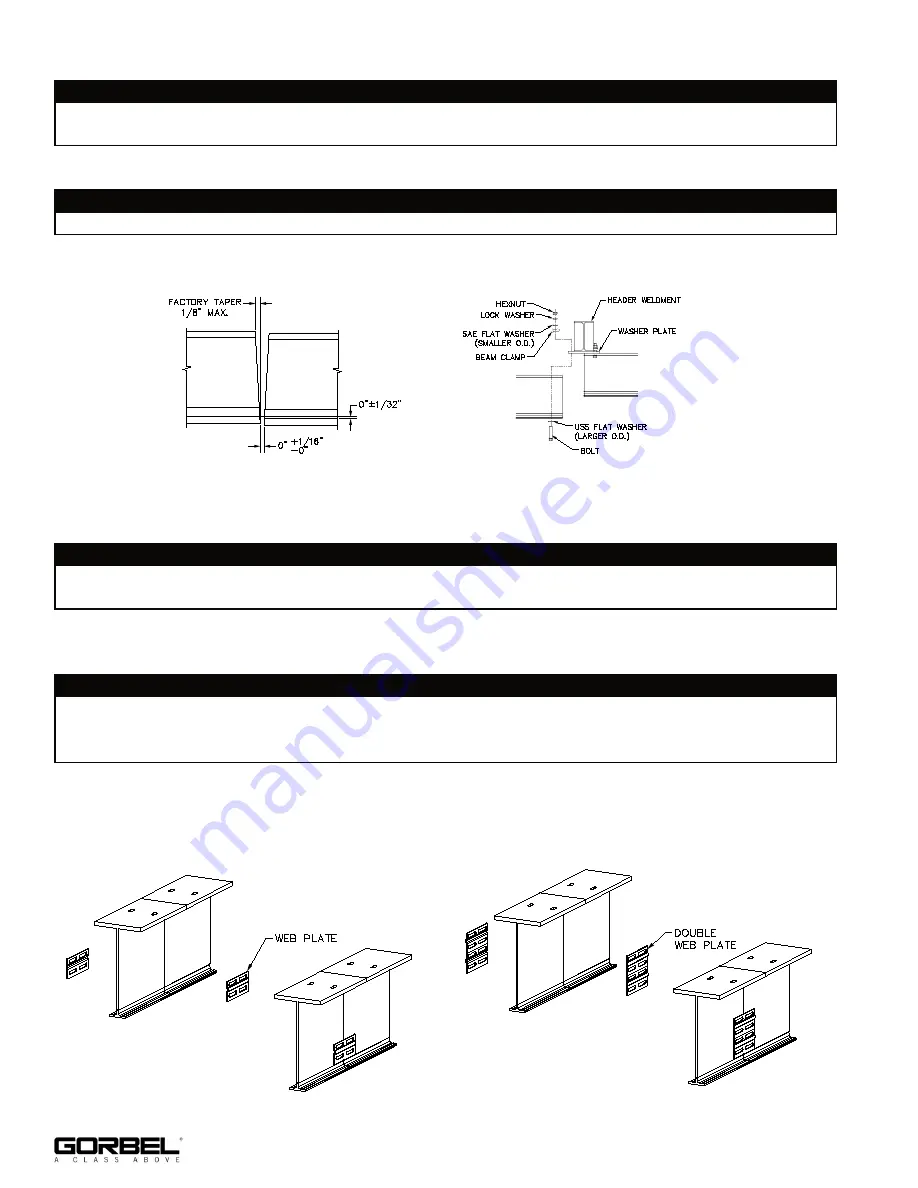

Splice Joint Instructions

4.6

Bring the ends of the track sections together as close as possible (

diagram 4C

).

4.7

Align holes in washer plate with the slots in the top flange of the rail. Tighten beam clamp

hardware. This will help align the top flange portion of track sections (

diagram 4D

).

4.8

Place web splice plate(s) on each side of web section. Align plate as shown (

diagrams

4E

and

4F

for welded splice or

diagrams 4H

and

4J

for bolted splice).

4.9

Web splice plates to be welded in accordance with American Welding Society (AWS)

specification D1.1 using E70xx electrodes (

diagram 4G

).

4.10

Check to see that the transition from one track to the other is smooth: no raised areas to

inhibit carrier or end truck operation (

diagram 4C

).

4.11

For additional runways repeat Steps 4.6 through 4.10.

WARNING

Reference the General Arrangement Drawing for splice locations. It will be necessary to install

adjacent runways at the same time.

WARNING

Track sections and web plate need to be carefully aligned before field welding of plates to

allow smooth transition between sections.

Diagram 4E.

Welded splice (4200-4600 Tarca® beam).

Diagram 4F.

Welded splice (5000 & Larger Tarca® beam).

WARNING

If welding of lower track is desired (not required), different electrodes are required for mild steel

vs. hardened steel. E7018 is used for mild steel only (web and top flange). E11018 must be

used for hard steel and may also be used for mild steel.

Diagram 4C.

Rail Alignment.

Diagram 4D.

Attaching header to top flange.

WARNING

If shimming runway, shim must be located between washer plate and top of runway.