STEP 5 - RUNWAY AND BRIDGE END STOP INSTALLATION (CONTINUED)

5.2

The standard end stops are for normal

applications where contacts with end stops are

infrequent and travel is at slow speed.

5.3

When service conditions are such that the

carrier, trolley, or crane will contact the end stop

frequently or at high speed, spring bumpers or

other energy absorbing type end stops are

available and should be used. For their

application and detail contact our Inside Sales

Department.

STEP 6 - BRIDGE AND END TRUCK INSTALLATION

FIRST STEPS:

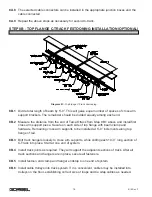

6.1

Prior to adding bridge, wipe rail tread with a clean, dry

cloth to remove grit or debris that may have collected

during shipping, storage, or installation.

6.2

Lay bridge girder on floor. Stabilize the girder so that it

cannot tip over.

6.3

Place endtrucks on top flange of girder and orient them so that the motors will be in the

desired location (

diagram 6A

- solid lines indicate standard motor position). Center the

endtruck to bridge connection bolt pattern on the girder. Make sure that the bridge span

exactly matches the distance between runway centerlines. Also confirm that the endtrucks

are square to the girder by matching diagonal measurements.

6.4

Transpose the bolt pattern from endtruck to bridge girder. Match mark endtrucks and

bridge.

6.5

Drill bolt holes (Ø 49/64”).

6.6

Bolt endtrucks into place. Confirm that the bridge span is correct and endtrucks are

square.

Diagram 6A.

If customer is supplying bridge, go to step 6.2. If

endtrucks and bridge are ordered together, start at

step 6.9.

Chart 5A.

Torque Chart.

9

9/18 Rev. F