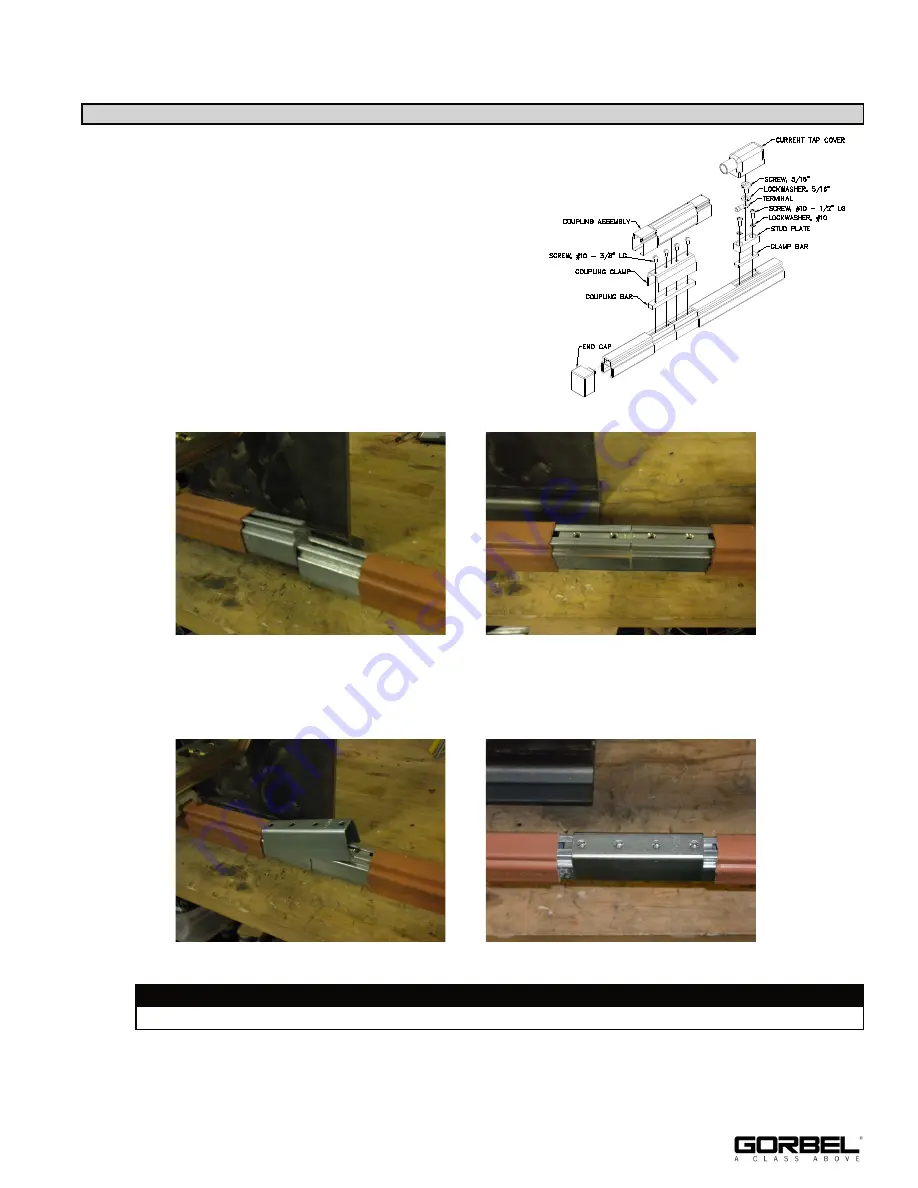

STEP 13 - RUNWAY CONDUCTOR BAR INSTALLATION (SAFPOWRBAR®) (CONT.)

(for Safe-Lec Runway Conductor Bar Installation, go back to Step 12, page 18)

Coupling Conductor Bars (Continued)

13.7

(See

diagram 13G

for complete assembly.) To

couple bars together, pull the two ends to be

joined apart and insert the coupling bar entirely

into the upper opening of one bar. Allow the

conductor bars to go back together and slide the

coupling bar half way into the adjoining bar so

that it is centered over the joint (

diagrams 13H

and

13J

).

13.8

Center the coupling clamp over the joint and tip to a 30-45 degree angle. Press one end

over the bar (

diagrams 13K

and

13L

).

13.9

Snap the coupling clamp down into place.

23

9/18 Rev. F

Diagram 13G.

Diagram 13H.

Diagram 13J.

Diagram 13K.

Diagram 13L.

WARNING

Do not spread clamp before installing, as clamp should be pressed onto bar.