INSTALLATION

STEP 1 - PRE-ASSEMBLY

1.1

Check packing list to make sure correct quantity of parts is included.

1.2

Tools and materials (by others) typically needed to assemble crane are as follows:

• Mallet

• Torque

wrench

• Chalk line

• Tape measure

• Hand tools

• Ladders/man lifts

• Grout

• Clamps (large C)

• Spud wrench

• Leveling tools (transit, laser level, water level, etc.)

• Shop brush

• Lifting device to lift heavy runways, bridges, headers

• Steel shims

• Welder (if splices are welded)

• Large square

• 3/4” anchor bolts (by others, see 1.3 for guidelines in

determining

length)

1.3

Recommended guidelines for determining bolt size and type:

Anchor bolts must:

• be 3/4” in diameter.

• be grade 5 or better.

• be embedded

at least

4” into

floor, not to exceed 3/4 of floor

depth (

diagram 1A

).

• have

minimum

of two threads

above nut.

Note:

A minimum 6”-thick reinforced concrete floor is required.

Note:

Free Standing Patented Track Bridge Crane foundation requirements are based on

a minimum soil pressure of 2500# per square foot. Concrete should be a minimum of

3000# per square inch of compressive concrete. Columns should be centered on a two

foot by two foot square area that is free from cracks, seams and walls.

Note:

Grout is required to ensure the base plate has full contact support to the floor/

footing. Shimming/leveling nuts under the base plate are acceptable methods that would

aid leveling of the columns prior to setting the columns on the grout bed (shimming/

leveling nuts by others). Grout must be a non-shrink, high compressive machinery type

grout.

Note:

Chemical (epoxy) anchor bolts are recommended. Chemical anchors to withstand a

minimum of 4880# of pull our force.

TIP:

Packing list can be found in envelope attached to hardware box: General Arrangement

Drawing can be found inserted in this installation manual.

TIP:

Recommended guidelines to help you determine anchor bolt size are supplied below

(anchor bolts are not included).

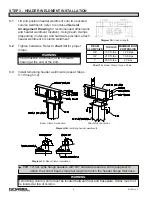

Diagram 1A.

Typical anchor bolt embedment.

2

9/18 Rev. F