13

10/12 Rev. E

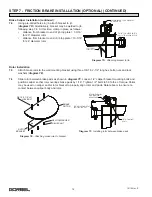

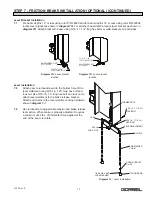

STEP 7 - FRICTION BRAKE INSTALLATION (OPTIONAL) (CONTINUED)

Lever Bracket Installation

7.7

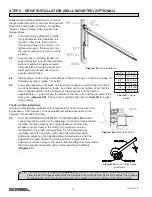

For beam depths 12” or less using rotor P/N 30520 and for beam depths 14” or less using rotor P/N 30534,

locate lever bracket as shown in

diagram 7G

. For all other beam depths, locate lever bracket as shown in

diagram 7H

. Attach bracket to beam using 5/16” x 1-1/4” long hex bolts or weld brackets on both sides.

Lever Installation

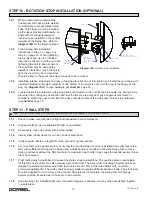

7.8

Attach cam to turnbuckle and to the bottom hole of the

lever weldment using 5/16-18, 1.25” long hex bolt and

lock nut. Use 5/16-18, 1.5” long hex bolt and lock nut to

attach lever weldment to the brake release bracket.

Attach pull chains to the lever weldment using hardware

show

in

diagram 7J

.

7.9

Use turnbuckle to adjust cable tension and brake release

lever action. When brake is properly adjusted it requires

a minimum of 40 lbs. of horizontal force applied at the

end of the boom to rotate.

5/16" x 1-1/4"

LONG HEX BOLTS

HANDLE BRACKET

P/N: 30555

Diagram 7G.

Lever bracket

location.

Diagram 7J.

Lever installation.

TURNBUCKLE

5/16-18, 1 1/2” LG

HEX BOLT

5/16-18, 1 1/4” LG

HEX BOLT

LEVER WELDMENT

S-HOOK

ENDWELDED

CHAIN

OPEN EYEBOLT,

1/4-20

ROUND KNOB

1/4-20 HEX NUT,

LOCKWASHER

CAM

5/16-18

LOCK NUT

5/16" X 1-1/4"

LONG HEX BOLTS

HANDLE BRACKET

P/N: 30557

Diagram 7H.

Lever bracket

location.