14

10/12 Rev. E

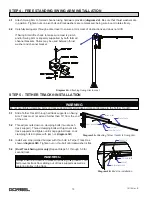

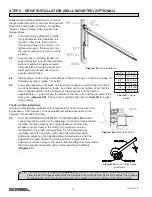

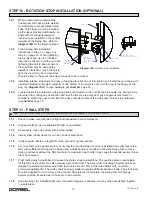

STEP 8 - DRIVE INSTALLATION (WALL MOUNTED) (OPTIONAL)

Holes must be drilled in wall column to mount

reducer assembly (refer to General Arrangement

Drawing for hole pattern, bolt size, and pattern

location). Spacer plates (when required) are

shipped loose.

8.1

The clutch is pre-tightened by Gorbel.

If any additional clutch adjustment is

required, refer to the friction clutch

instructions

below.

If the clutch is not

tightened properly, the lever arm may

slip and the Swing Arm may not rotate

properly.

8.2

Layout reducer mounting location on

support structure. Ensure that mounting

surface of support structure is plumb

along the plane comprising upper and

lower pivot mounts and drive mount.

Locate and drill holes.

8.3

Install swing arm according to instructions in Step 2 on page 7 or Step 4 on page 10.

Hardware by others (grade 5 or better).

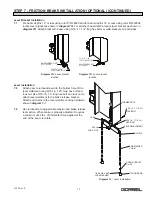

8.4

Lower drive assembly into place with lever arm engaged on pivot block and install

mounting hardware (grade 5 or better, by others) but do not tighten. Verify that the

drive is aligned with the axis of rotation of the swing arm and that there is

approximately a 1” gap between the bottom of the lever arm and the top plate of the

Swing Arm (

diagram 8B

). Torque drive mounting bolts (refer to

chart 8A

for proper

torque

rating).

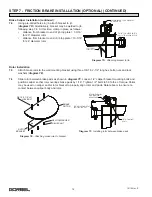

Friction Clutch Installation

During normal operation, adjustment to compensate for friction lining wear may

be necessary. The frequency of these adjustments will be dependent on the

frequency of overloads occurring.

8.5

CLUTCH TORQUE ADJUSTMENT - SYSTEMS USED INDOORS

Loosen the locking screw on the adjusting nut. Using the hook wrench

provided, turn the adjusting nut counterclockwise until the drive

sprocket can turn freely in the clutch. The clutch can now be

retightened to the proper torque setting. Turn the adjusting nut

clockwise until it is hand tight. Using the hook wrench provided,

tighten the adjusting nut an additional two full revolutions. After the

adjustment is made, tighten the locking screw to ensure that the

adjusting nut doesn’t loosen. The proper torque setting is achieved when

the drive sprocket will not slip under

normal

operating conditions

(

diagram 8C

).

Diagram 8A.

Drive installation.

Bolt Dia.

Torque

1/2”

50 ft.-lbs.

5/8”

95 ft.-lbs.

3/4”

175 ft.-lbs.

7/8”

300 ft.-lbs.

1”

450 ft.-lbs.

Chart 8A.

Torque

ratings.

TIP:

The friction clutch is shipped

pretightened

by Gorbel. If the clutch begins to slip during initial use,

allow the clutch to slip several times then retighten the clutch per the instructions below. The purpose

for allowing the clutch to slip several times is to establish a uniform surface on the friction linings.

Diagram 8C.

Indoor clutch torque

adjustment.

Diagram 8B.

Drive clutch detail.