STEP 4 - RUNWAY OR MONORAIL INSTALLATION (CONTINUED)

4.8

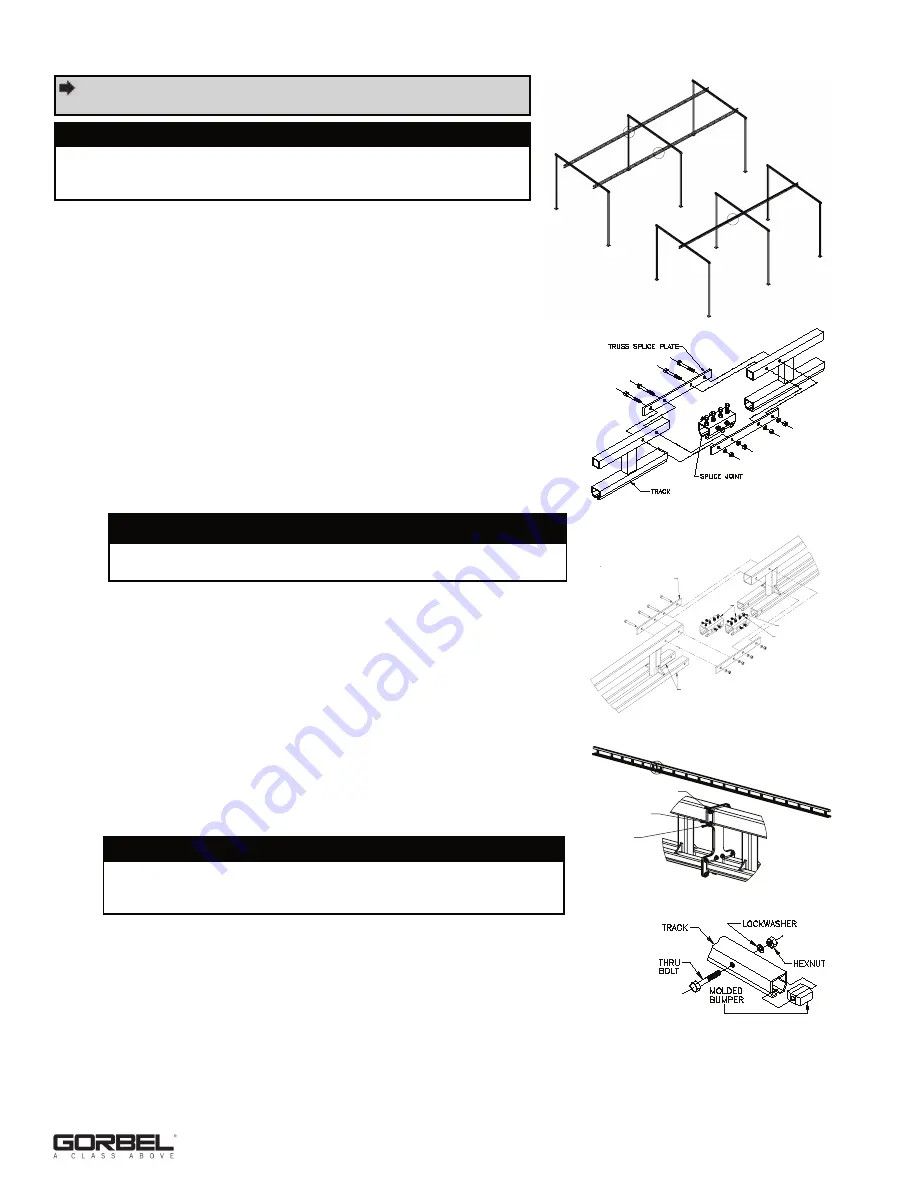

Place a truss splice plate on each side of runway truss tube and bolt

into place, as shown in

diagram 4C

or

4D

. “Hand- tighten” bolts.

Note:

Do not torque bolts until track has been attached to header

weldment and adjusted for smooth transition - Steps 4.9 through 4.10.

4.9

To attach track to header weldment, repeat Steps 4.2 through 4.4,

on page 7.

4.10

To adjust track for smooth transition, use bolts along

top of splice joint

to force track down onto lower flanges of splice. Check to see that

transition from one track to the other is smooth: no raised areas to inhibit

trolley or end truck operation. Use bolts along the

sides of splice joint

to

align track laterally. Check to see that track portion of runway is

horizontally and vertically flush: transition from one track to the other is

smooth. Tighten jam nuts to lock bolts in place (refer to

diagram 4C

or

4D

).

Note:

Track running-surface misalignment at joints shall be adjusted

within 1/32” (1mm) when installed.

4.11

Tighten nuts on truss splice plate to full compression of lockwasher, do

not exceed 40 ft.-lbs.

For Z and ZD tracks:

4.12

Refer to the General Arrangement Drawing to plan the sequence in

which the monorail sections will be installed. Monorail sections that have

splice plate style connections (Z and ZD styles) may need to be

assembled to the mating monorail section prior to lifting and installing on

the headers. Do not lift greater than two assembled (splice plate style

connection only) monorail sections at a time. Do not lift assemblies

greater than 54 feet long. Do not allow more than 13 feet of track to

extend past the header without support. For sleeve and truss plate style

connections (S, SL, SLX and SLD styles), only lift these sections

individually (not assembled).

4.13

Splice Joint Plate Style Connections:

Align mating monorail sections and install

hardware (

diagram 4E

). Verify track flanges (trolley wheel running surfaces) are aligned

before tightening. Run a finger on the inside of the track flange and use a soft blow

mallet to align plates until no lip is felt. Also check alignment of mating sections for bow

and camber. Steel shims (by others) may be used between the splice plates to adjust

any misalignment. Tighten hardware to 50 ft.-lbs. of torque per nut.

4.14

Repeat Steps 4.6 through 4.11 for remaining runways.

4.15

Install end stops as shown in

diagram 4F

(molded bumper with thru bolt) to one end of runway or monorail

(leaving other end open for bridge or trolley installation). Tighten nut on thru bolt to full compression of

lockwasher.

WARNING

Do not over-tighten bolts on splice joints; this may permanently

deform track and cause binding.

IMPORTANT:

To install additional runway sections, runways

must be spliced together.

Diagram 4C.

Splicing tracks together.

Diagram 4F.

Installing end stop.

8

9/18 Rev C

WARNING

Do not deviate from the dimensions specified in the General

Arrangement Drawing for maximum space from header center to

splice joint. Typically 48” maximum.

JAM NUT

TRUSS SPLICE PLATE

CLAMPING BOLT

DUAL TRACK

SPLICE JOINTS

Diagram 4D.

Splicing dual trussed track.

1/2"-13 X 1-1/2" HHCS

FLAT WASHER

LOCK NUT

Diagram 4E.

Plate style splice joint detail.

WARNING

The locations of the runways cannot deviate from the locations

shown on the drawing. Changing the locations will void the design

and the warranty.