INSPECTION AND MAINTENANCE SCHEDULE

*Federal, state and local codes may require inspection and maintenance checks more often. Please check

the federal, state and local code manuals in your area. Gorbel recommends a certification inspection

interval of no more than one year by a qualified person.

18

9/18 Rev C

1

3

4

5

6

6

6

7

7

2

9

10

8

600 Fishers Run, P.O. Box 593

Fishers, NY 14453-0593

Distributed by Engineered Fall Protection

Sales@EngineeredFallProtection.com

www.EngineeredFallProtection.com

Tel: (314) 492-4422

© 2012 Gorbel, Inc.

All Rights Reserved

GORBEL® TETHER TRACK® FREE STANDING BRIDGE AND MONORAIL ANCHOR SYSTEMS:

INSPECTION AND MAINTENANCE SCHEDULE

ITEM

COMPONENT

MAINTENANCE

FREQUENCY*

1 Anchor Bolts

Check that lockwashers are compressed and nuts tightened to

manufacturer’s specifications. Check foundation for cracking.

Every 2,000 hours

or yearly.

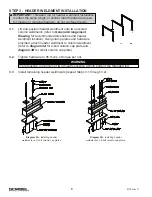

2 Header Clamp Plate

Hardware

Check for full compression of lockwasher. Bolts should be

tightened to 95 ft.-lbs.

Every 2,000 hours

or yearly.

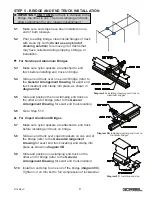

3 Spine Clamp Hardware

Bolts should be tightened to full compression of lockwasher. Do

not exceed 50 ft.-lbs.

Every 2,000 hours

or yearly.

4 Truss Splice Plate

Check for full compression of lockwasher. Bolts should be

tightened to 40 ft.-lbs.

Every 2,000 hours

or yearly.

5 Splice Joint

All bolts should be in contact with track. Check track for

alignment and that wheel rolling surface is flush.

Every 2,000 hours

or yearly.

6 End Stops (runway,

bridge and monorail)

Check for full compression of lockwasher. If thru-bolt is exposed,

replace endstops.

Every 2,000 hours

or yearly.

7 Wheels (endtrucks and

trolleys)

Check for cracks, pits, and/or grooves: all of these affect

trolley tracking. If any of these conditions exist, wheels should be

replaced.

Every 2,000 hours

or yearly.

8 Tether Trolley

Connector

Check eyenut for wear. Check that clamp plate lockwashers are

compressed. Check that black spring washer is not deformed

and is in place. Confirm spring pin is in place. Check for smooth

rolling action.

Recover Trolley only:

Check that guide bushing

bolts are tightened to 10 ft-lbs and bushings spin freely.

Every 2,000 hours

or yearly.

9 End Trucks

Check for proper clamping hardware attachment. Ensure

correct position on bridge to match specified cantilevers. Make

sure body is free of any bent materials, cracked or broken welds.

Every 2,000 hours

or yearly.

10 Aluminum Bridge

Assembly Hardware

Ensure sheer lug hardware is in required position and tight. For

coped bridge, tighten 3/8” bridge bracket hardware to 20 ft.-lbs.

Every 2,000 hours

or yearly.

11 Capacity and Warning

Labels

Check that all labels are in place and legible. Replace labels if

damaged or illegible.

Every 2,000 hours

or yearly.

12 Connecting Equipment

Inspect all protective equipment connected to the Tether Track®

Anchorage System following the operation and maintenance

manuals provided for each piece of equipment.

As required by

manufacturer.

WARNING

Any changes in rolling effort or unusual noises

must be immediately identified and corrected.

It is not necessary to lubricate the track or

bearings. Lubricating may attract airborne

particles and may increase the rolling

resistance. (Do not use such substances as

WD-40®, silicone sprays, oil or grease on

bearings or on track flanges.)