INTRODUCTION

Thank you for choosing Gorbel® Tether Track® Free Standing Rigid Rail Anchor Systems to solve your

fall protection needs. The innovative design and heavy-duty construction of the Gorbel® Tether Track®

Anchor Systems will provide a superior quality product that will offer years of long term value. Gorbel®

Tether Track® Anchor Systems have been optimally designed and tested to provide the ultimate solution

for fall arrest systems. When properly applied, configured and installed under the supervision of a

qualified person, Tether Track® Rigid Rail Anchor Systems will allow the ultimate in user mobility by

providing a mobile rigid anchorage for the attachment of a lanyard or self-retracting lanyard (SRL). This

reliable performance combined with an ANSI approved Managed Fall Protection Program gives the user

the utmost safety assurance and encourages further safe work practices.

Tether Track® Rigid Rail Anchor Systems are designed using ANSI guidelines and comply with all OSHA

requirements for a fall arrest anchorage system. Tether Track® Free Standing Rigid Rail Anchor Systems

are designed to be statically proof tested up to 110% of the maximum arresting force (MAF). When loaded

through proof testing or during a fall event, the Tether Track® Rigid Rail Anchor Systems will not incur

any visual permanent deformation and may be placed back into service after performing the inspection

requirements detailed in this manual. All engineered Tether Track® Rigid Rail Anchor Systems comply with

OSHA’s required safety factor of 2 and are designed in accordance with ANSI Z359.6. Gorbel® Tether

Track® Anchor Systems will provide many years of dependable service by following the installation and

maintenance procedures described herein.

APPLICATION

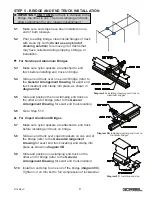

A Gorbel® Tether Track® Free Standing Monorail Anchor System is the best choice for providing

coverage to a narrow rectangular fall zone when an existing support structure is unavailable or

inadequate. The rigid, self-tracking, overhead trolley anchorage, combined with the use of a “Class A”

Self Retracting Lanyard, provides the best solution to minimize fall distance when fall clearance height is

restrictive.

Note:

Specify Class A requirement at time of quote, standard design is for 900 pounds MAF.

A Gorbel® Tether Track® Bridge System offers the best solution to a wide rectangular fall zone.

Combined with an SRL, this system allows for user mobility in 3 dimensions. A low inertia bridge

(standard lengths to 18’) glides effortlessly on runways, keeping both the anchorage trolley and bridge

directly above the user. No other systems eliminates swing falls as well as a Gorbel® Tether Track®

Bridge Rigid Rail Anchorage System.

This product meets all applicable OSHA and ANSI standards for fall protection.

Dimensions contained in this installation manual are for reference only and may differ for your

particular application. Please refer to the enclosed General Arrangement Drawing for actual

dimensions.

Normal safety precautions:

These include, but are not limited to:

• Checking for obstructions in the fall clearance zone

• Coordinating fall hazard activities with assigned rescue personnel

• Making sure that end stops are in place

• Making sure that the trolley and bridge freely move

For additional safety precautions, see page 13.

1

9/18 Rev C