INSTALLATION

STEP 1 - PRE-ASSEMBLY

1.1

Read entire installation manual

before

you begin installing your Tether Track® Anchor

System.

1.2

Check packing list to make sure correct quantity of parts is included.

1.3

Tools and materials (by others) typically needed to assemble crane are as follows:

• Mallet

• Torque wrench (able to torque up to 95 ft.-lbs.)

• Chalk line

• Tape measure

• Hand

tools

• Ladders/man lifts (transit, laser level, water level, etc.)

• Shop brush

• Leveling tools

• Steel shims

• Lifting device to lift heavy runways, bridges, headers

•

Large

square

•

Anchor bolts (by others, see 1.4 for guidelines in

• Drill

determining size)

1.4

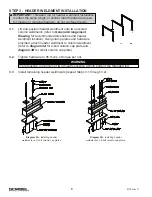

Recommended guidelines for post-installed anchor bolts:

Note:

In addition to the anchor bolt load requirements stated on the quote form, a

minimum 6” thick reinforced concrete floor with a supporting area that is four times

greater than the base plate area and is free of cracks, seams, expansion joints,

and walls is required. Foundation requirements are based on a concrete

compressive strength of 3000# per square inch.

Anchor bolts shall:

• have an ICC-ES listing

demonstrating

suitability for the

application.

• be installed in

accordance with the

manufacturer’s

instructions and

requirements.

Note:

Chemical (epoxy)

anchor bolts are recommended.

Note:

Hole size may exceed anchor bolt manufacturer’s recommendations. If base plate

hole diameter is greater than bolt diameter plus 1/4”, refer to AISC Design Guide 1

for minimum washer size and thickness recommendations.

TIP:

Packing list can be found in a plastic pocket attached to the hardware box: General

Arrangement Drawing and additional inserts can be found enclosed in this installation

manual.

TIP:

Recommended guidelines to help you determine anchor bolt size are supplied below

(anchor bolts are not included).

Diagram 1A

Typical anchor bolt embedment.

4

9/18 Rev C