9

12

HOW TO ADJUST BELT TENSION:

MODEL GO 68HD, GO 380/250 SERIES

1. LOOSEN MOTOR MOUNTING SCREWS.

2. ADJUST MOTOR AS NEEDED..

3. MAKE SURE PULLEY’S ARE IN LINE.

4. REFASTEN MOTOR MOUNTING SCREWS.

PROPER BELT TENSION FOR ALL MODELS SHOULD BE 1/4” BELT MOVEMENT IN EITHER DIRECTION.

COVER HOUSING MUST BE REMOVED ON MODEL GO 380/250 SERIES.

MODEL GO 68, GO 62 SERIES

1. LOOSEN BELT TENSIONER HEX BOLTS.

2. ADJUST BELT TENSION PLATE AS NEEDED.

3. MAKE SURE PULLEY’S ARE IN LINE.

4. REFASTEN BELT TENSIONER HEX BOLTS.

MODEL GO 50 SERIES

1. LOOSEN UPPER AND LOWER NUTS ON

MOUNTING BOLTS.

2. RAISE OR LOWER MOTOR FOR RIGHT BELT

TENSION.

3. CHECK ALIGNMENT OF BELT AND PULLEYS.

4. REFASTEN ALL NUTS.

MODEL GO 15

1. REMOVE TRUNK, PILLOW BLOCK AND DRUM.

2. LOOSEN MOTOR MOUNTING NUTS.

3. ADJUST MOTOR FOR PROPER BELT TENSION.

4. REFASTEN ALL MOTOR MOUNTING NUTS.

5. REINSTALL DRUM, PILLOW BLOCK AND

TRUNK.

DRUM MUST BE REMOVED BEFORE BELT TENSION CAN BE PERFORMED.

DO NOT OVER TIGHTEN BELT TENSION, AS YOU WILL RAISE MOTOR SHAFT, LOOSEN

AND WEAR OUT SEALS AND EXPERIENCE THE LOSS OF GEAR LUBRICANT.

HOW TO ADJUST BELT TENSION

MODEL GO 68, GO 68HD, GO 62 SERIES

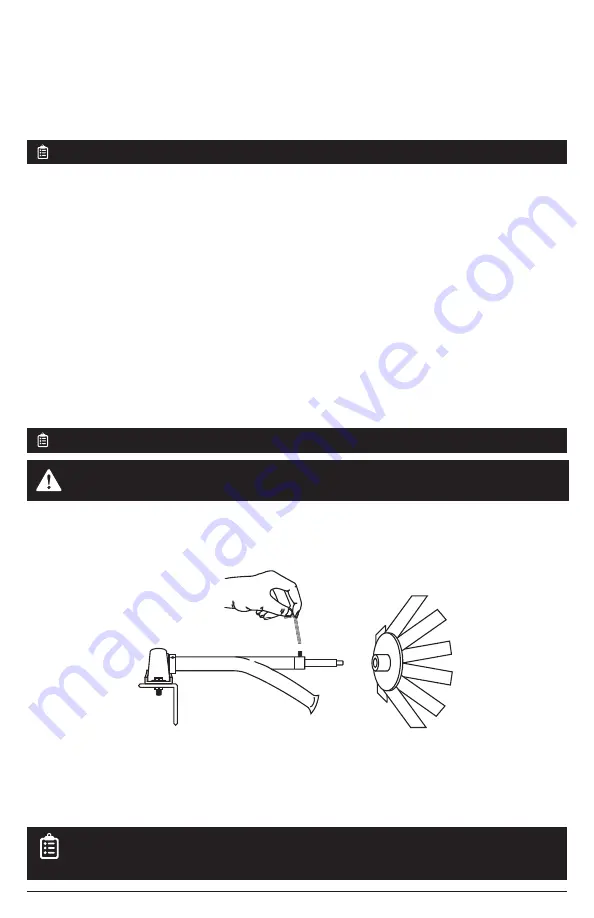

CABLE IS ALWAYS UNDER TENSION. DO NOT LET CABLE FLY OUT OF CAGE.

WHEN INSTALLING REEL, REVERSE PROCEDURE. BE POSITIVE DRIVE PLATE ENGAGE

PROPERLY INTO BACK OF REEL.

1. PUSH CABLE INTO DRIVE ARM..

2. LOOSEN SET SCREW ON DRIVE EXTENSION.

3. PUSH DRIVE ARM EXTENSION INTO DRIVE

ARM BUSHING.

4. PULL DRIVE ARM OUT OF FRONT BEARING.

5. REMOVE REMAINING CABLE FROM DRIVE

ARM AND PLACE INTO REEL.

6. SLIDE REEL FORWARD AND OFF DRIVE

SHAFT.

9 Gorlitz Operating & Maintenance Manual