GMS SERIES

OM-04386

PAGE D-4

TROUBLESHOOTING

PREVENTIVE MAINTENANCE

Since pump applications are seldom identical, and

pump wear is directly affected by such things as

the abrasive qualities, pressure and temperature

of the liquid being pumped, this section is intended

only to provide general recommendations and

practices for preventive maintenance. Regardless

of the application however, following a routine pre

ventive maintenance schedule will help assure

trouble‐free performance and long life from your

Gorman‐Rupp rotary gear pump. For specific

questions concerning your application, contact

your Gorman‐Rupp distributor or the Gorman‐

Rupp Company.

Record keeping is an essential component of a

good preventive maintenance program. The ap

pearance of wearing parts should be documented

at each inspection for later comparison. Also, if re

cords indicate that a certain part (such as the seal)

fails at the same duty cycle, this part can be

checked and replaced before failure occurs.

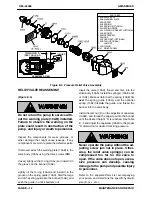

Because of the tight tolerances within your rotary

gear pump, wear between rotating parts is normal

and expected. For new applications, a first inspec

tion at 250 hours will give insight into the wear rate

for your particular application. Subsequent inspec

tions should be performed at regular intervals of

2000 hours. Critical applications should be in

spected more frequently.

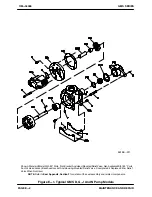

Check the thrust washer, idler bushing, idler pin,

idler assembly, shaft bushing and rotor/shaft as

sembly at each inspection. Wear patterns should

be uniform, without evidence of deep or irregular

grooves.

For packing pumps, periodic adjustment of the

packing is required to keep leakage to a minimum

(see the adjustment procedure described under

Leakage

in

Operation, Section C

). Do not over

tighten. Replace the packing if leakage cannot be

reduced by a slight adjustment.

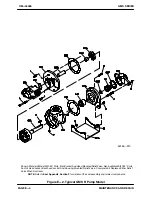

After extended service, adjustment of the clear

ance between the rotor and the head will normally

improve performance (see the adjustment proce

dure in

Maintenance And Repair, Section E

).

If the pump is to be removed from service for repair,

be sure to protect the internal components from

rusting while the pump is disassembled and after

reassembly if not immediately placed back into

service.