OM-04386

GMS SERIES

PAGE E-8

MAINTENANCE AND REPAIR

lated components, then proceed as follows with

pump disassembly.

Remove the nuts (D) and slide the stuffing box

(04N) off the rotor shaft assembly (03A). Remove

the stuffing box gasket (05P).

Remove the seal assembly (05) and related com

ponents as described in

Seal Appendix, Section

F

.

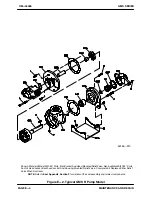

Backhead Removal (06, R Size Only)

(Figure E‐2 Only)

Disengage the screws (B) securing the backhead

(06A) to the housing assembly (04) and separate

the assemblies. Remove and discard the gasket

(06B).

NOTE

The shaft bushing (04B) may be damaged during

removal. Do not remove the shaft bushing unless

replacement is required.

If your pump is equipped with a graphite or silicon

carbide shaft bushing (04B), the old bushing can

be removed by breaking it into pieces using a ham

mer and chisel.

Use caution

not to damage the I.D.

of the backhead.

If your pump is equipped with a bronze shaft bush

ing, the bushing must be machined out of the

backhead.

Use caution

not to damage the I.D. of

the backhead.

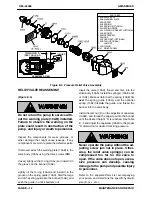

Rotor/Shaft Removal (03)

Slide the rotor/shaft assembly (03A) out of the

housing (04A). Due to close machine tolerances

and assembly practices, the rotor/shaft is available

only as an assembly. Further disassembly is not re

quired.

Seal Removal (05)

The seal assembly (05) is available in a variety of

configurations. Check the

Parts List

furnished with

your pump to identify the seal, then refer to

Seal

Appendix

,

Section F

, for removal of the seal and

related components.

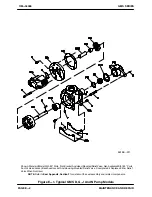

Housing Assembly (04, D, G, J, N Sizes Only)

(Figure E‐1 Only)

NOTE

The shaft bushing (04B) may be damaged during

removal. Do not remove the shaft bushing unless

replacement is required.

If your pump is equipped with a graphite or silicon

carbide shaft bushing (04B), the old bushing can

be removed by breaking it into pieces using a ham

mer and chisel.

Use caution

not to damage the I.D.

of the housing.

If your pump is equipped with a bronze shaft bush

ing, the bushing must be machined out of the

housing.

Use caution

not to damage the I.D. of the

housing.

PUMP REASSEMBLY

Use caution when handling the idler (02A)

and the rotor shaft assembly (03A). These

parts have sharp edges which will grow

sharper with use.

Cleaning and Inspection

Most cleaning solvents are toxic and

flammable. Use them only in a well ven

tilated area free from flame, sparks, and

excessive heat. Read and follow all pre

cautions printed on solvent containers.

Clean and inspect the pump parts (except the seal

assembly) with a cloth soaked in fresh cleaning

solvent. Inspect all parts for excessive wear or for

any nicks or burrs. Remove nicks or burrs using

emery cloth or a fine file. Replace any parts that are

badly worn or damaged.

Clean and inspect the seal assembly as indicated

in the appropriate section of the

Seal Appendix,

Section F

.