GMS SERIES

OM-04386

PAGE E-9

MAINTENANCE AND REPAIR

Bushing Preparation

When replacing bushings, lightly oil the O.D. of the

replacement bushing before installation.

Be very careful

when installing graphite

bushings. Graphite is extremely brittle and

will crack if improperly installed. Use a

press to install the bushing with one contin

uous motion until the bushing is fully

seated. Stopping in mid‐stroke will cause

the bushing to crack. After installation,

check the bushing for cracks.

NOTE

When installing

high temperature graphite bush

ings

, heat the part that receives the bushing to

500

F and place the bushing in a freezer for at least

one hour. This will allow easy installation without

breakage and provide a tight shrink fit after cooling.

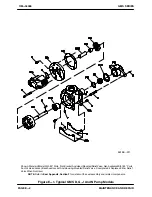

Housing Assembly (04)

Clean and inspect the housing (04A) with a cloth

soaked in fresh cleaning solvent. Replace the

housing if badly worn or damaged.

Most cleaning solvents are toxic and

flammable. Use them only in a well ven

tilated area free from flame, sparks, and

excessive heat. Read and follow all pre

cautions printed on solvent containers.

When installing a replacement shaft bushing (04),

position the housing on the bed of an arbor (or hy

draulic) press with the drive end facing down.

Press the bushing into the housing until fully

seated against the bore shoulder.

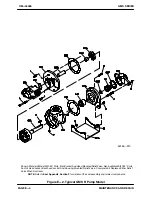

Backhead (06)

(Figure E‐2 Only)

Clean and inspect the backhead (06) with a cloth

soaked in fresh cleaning solvent. Replace the

backhead if badly worn or damaged.

Most cleaning solvents are toxic and

flammable. Use them only in a well ven

tilated area free from flame, sparks, and

excessive heat. Read and follow all pre

cautions printed on solvent containers.

When installing a replacement shaft bushing (04),

position the backhead on the bed of an arbor (or

hydraulic) press with the drive end facing down.

Press the bushing into the backhead until fully

seated against the bore shoulder.

Be very careful

when installing graphite

bushings. Graphite is extremely brittle and

will crack if improperly installed. Use a

press to install the bushing with one contin

uous motion until the bushing is fully

seated. Stopping in mid‐stroke will cause

the bushing to crack. After installation,

check the bushing for cracks.

NOTE

When installing

high temperature graphite bush

ings

, heat the part that receives the bushing to

500

F and place the bushing in a freezer for at least

one hour. This will allow easy installation without

breakage and provide a tight shrink fit after cooling.

Install a new gasket (06B) and secure the back

head to the housing (04A) with the previously re

moved capscrews (B).

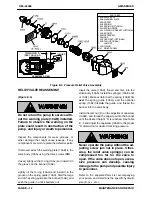

Rotor/Shaft Assembly (03)

Inspect the rotor/shaft assembly (03A) for exces

sive wear, scoring or scratches along the shaft

sealing surface. If replacement is required, the