OM-04386

GMS SERIES

PAGE F - 4

SEAL APPENDIX

Seal Removal

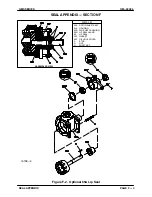

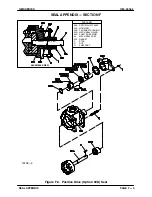

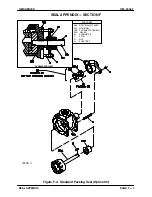

(Figures E‐1 and F‐2)

Separate the pump and driver and remove the

shaft key (N).

There are no provisions for draining oil from the

reservoir between the two oil seals (05). Place a

drip pan under the drive end of the pump and thor

oughly clean up any spillage that may occur.

Remove the nuts (D) and slide the gland (04N) and

lip seals (05)off the shaft as a unit. Remove the

gasket (05P).

Use a dowel or other suitable tool to press the lip

seals out of the gland.

It is not necessary to remove the shaft snap ring

(05D) unless the rotor and shaft assembly (03A) is

to be removed. Use snap ring pliers to remove the

snap ring if required.

Continue as required with

PUMP DISASSEMBLY

.

Seal Installation

(Figures E‐1 and F‐2)

See

PUMP REASSEMBLY

, and reassemble the

pump up to the rotor and shaft assembly (03A).

Clean the seal cavity and shaft with a cloth soaked

in fresh cleaning solvent.

Most cleaning solvents are toxic and

flammable. Use them only in a well ven

tilated area free from flame, sparks, and

excessive heat. Read and follow all pre

cautions printed on solvent containers.

Lightly lubricate the I.D. of the gland (04N) with oil.

Press the lip seals (05) into the gland with the lips

positioned as shown in Figure F‐2.

Install a new gasket (05P) over the shoulder on the

back of the housing (04A).

Lubricate the lip seal areas on the shaft with oil.

Carefully slide the assembled gland and lip seals

onto the shaft until the gland seats against the gas

ket.

Use caution

not to roll or cut the lip seals on

the shaft keyway.

Install the nuts (D) and tighten them alternately un

til the gland is fully seated.

Lubricate the lip seals as indicated in

Barrier Liq

uids for Optional Double Lipseal

in

Installation,

Section B

.

Reinstall the shaft key (N) and reconnect the driver.