OM-04386

GMS SERIES

PAGE F - 8

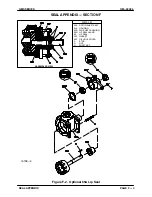

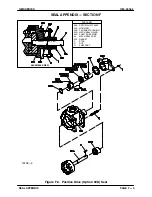

SEAL APPENDIX

Seal Removal

(Figures E‐1 and F‐4)

Separate the pump and driver and remove the

shaft key (N).

Remove the nuts (D) and slide the gland (04N) and

packing rings (05) off the shaft as a unit. Remove

the gasket (05P).

Use a stiff wire with a hooked end to pull the pack

ing rings out of the gland.

Continue as required with

PUMP DISASSEMBLY

.

Seal Installation

(Figures E‐1 and F‐4)

See

PUMP REASSEMBLY

, and reassemble the

pump up to the rotor and shaft assembly (03A).

Clean the seal cavity and shaft with a cloth soaked

in fresh cleaning solvent.

Most cleaning solvents are toxic and

flammable. Use them only in a well ven

tilated area free from flame, sparks, and

excessive heat. Read and follow all pre

cautions printed on solvent containers.

NOTE

It is recommended that replacement packing rings

pre‐cut to the correct width and length and pack

aged in sets (see the separate Parts List accompa

nying your pump) be ordered from your Gorman‐

Rupp distributor or the factory. However, if bulk

commercial packing will be used, prepare and in

stall it in accordance with the steps outlined below

in order to ensure that the packing will form a tight

seal.

Figure F‐4A.

Step 1:

Determine how much bulk packing will be

required to fill the seal cavity and wrap it around a

rod the same diameter as the shaft. With the pack

ing wrapped around the rod, cut through each turn

as shown in Figure F‐4A.

If the cut rings are too thick and will not fit in the

packing cavity, place each turn on a clean piece of

paper and use a length of pipe to roll the ring until

the thickness has been reduced.

Never

attempt to

flatten a packing ring with a hammer.

Right

Wrong

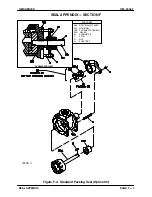

Figure F‐4B.

Step 2:

It is critical that the ends of the cut packing

ring meet in a tight parallel fit to ensure proper seal

ing. Check this fit; it should be correct if the packing

was cut while wrapped around a rod, but if the

packing was cut while laid out straight the ends will

meet at an angle.

Never

install packing rings with

an angled gap; pressure on adjacent packing

rings will cause them to work into the gap and pre

vent the angled ring from closing properly around

the shaft.