OM−05229

JSV3H

PAGE E − 10

MAINTENANCE AND REPAIR

3.

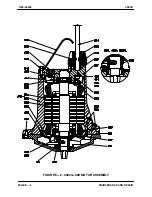

Slide the lower bearing (207) onto the shaft un-

til fully seated, install the support ring (208),

and secure with the retaining ring (209).

NOTE

If the bearings were heated, allow them to cool and

then check to make sure that they has not shrunk

away from the shaft shoulders. If the bearings have

shifted, use a suitable sleeve and a press to fit the

bearings snug against the shoulders.

4.

If heating the bearings is not practical, use an

arbor (or hydraulic) press and a suitable sized

sleeve to press the bearings onto the shaft until

fully seated.

5.

Slide the rotor and shaft and assembled bear-

ings into the lower bearing housing (213) until

the lower bearing (207) is fully seated, and se-

cure the bearing with the retaining ring (206).

Installing Shaft and Rotor Assembly

NOTE

The stator (301) is a hot shrink fit in the motor hous-

ing (302). No instructions are given in this manual

for separating the stator, motor housing, or thermal

protectors (307). It is strongly recommended that

the stator/motor housing be returned to the factory

or an authorized Gorman-Rupp repair facility if any

of the components require service.

1.

Lightly lubricate a new O-ring (252) and install

it in the groove in the bearing housing (213).

2.

Slide the assembled rotor and shaft and lower

bearing housing into the motor housing, and

use a soft-faced mallet to tap around the lower

bearing housing until fully seated in the stator

housing (302).

3.

After the motor is fully assembled, lubricate the

motor as indicated in

LUBRICATION

at the

end of SECTION E.

Installing Motor Cover

1.

Clean the exterior of the motor cable (234) with

warm water and mild detergent, and inspect

for obvious damage. (If required, see

ELEC-

TRICAL TESTING

in

TROUBLESHOOTING

,

SECTION D.)

Do

not

splice the cable. waterproof integri-

ty must be maintained. If repairs are re-

quired other than at either end, replace the

entire cable.

2.

If the cable inlet (236), cable clamp (238), and

rubber seal (235) have been moved or re-

moved, lubricate the motor cable (234) to ease

moving the parts during installation.

3.

Install the cable inlet (236) and cable clamp

(238). Discard the old rubber seal (235) and in-

stall a new one above the deformation mark left

on the motor cable by the old seal.

4.

Cut the motor cable (234) above the seal defor-

mation mark. Strip the motor cable outer insu-

lation so that the individual leads are long

enough to make motor connections; the

ground lead must be longer than the others.

5.

Remove the identification sleeves from the cut

power leads, and install on the new wire ends.

Install identifying sleeves or markers identical

to those on the old leads on the new leads.

6.

Pull the rubber seal (235) down to within two

inches (50,8 mm) of the end of the motor cable

sheath (234). Pull the cable clamp (238) down

until flush with the rubber seal. Lubricate the

outside of the cable clamp, and pull the cable

inlet (236) down over the clamp until flush with

the cable clamp.

7.

Insert the motor cable leads into the motor

cover (230), making certain that the rubber

seal bottoms in the cover, and that the cable

clamp (238) and cable inlet (236) are flush with

the top of the cover. Secure the cable inlet and

installed components with the screws (237).