JSV3H

OM−05229

PAGE B − 3

INSTALLATION

Field Wiring Connections (Incoming Power)

Field wiring is

not

provided with this pump, and

must be supplied by the user. The field wiring must

be of the proper size and type to ensure an ade-

quate voltage supply to the pump. Voltage avail-

able at the motor must be within the range indi-

cated in Table B-2.

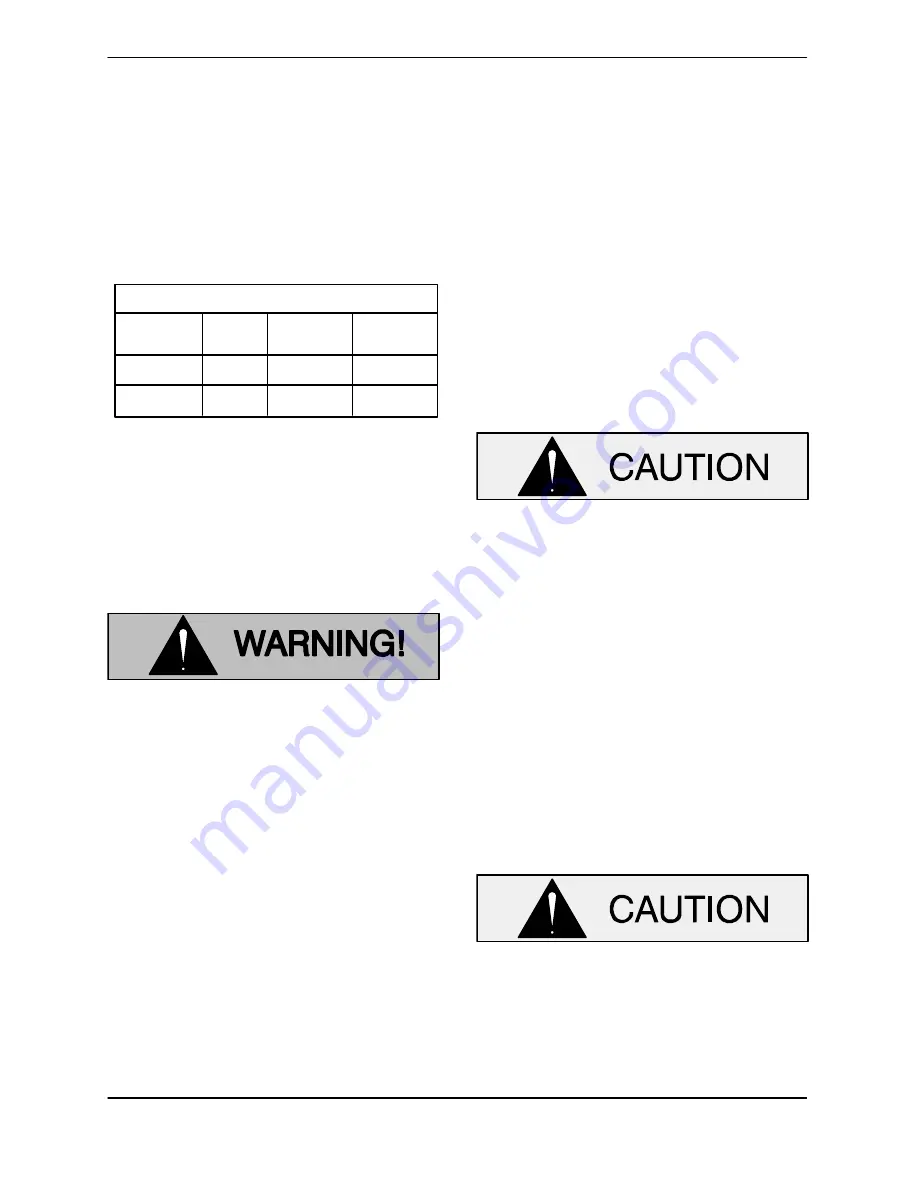

TABLE B-2. MOTOR VOLTAGE LIMITS

NOMINAL

VOLTAGE

3

200

180

220

PHASE

MINIMUM

VOLTAGE

MAXIMUM

VOLTAGE

3

230

205

260

Use conduit cable clamps to secure the incoming

field wiring to the control box. Make certain all con-

nections are tight. If necessary, support the cable

weight to prevent excessive strain on cable clamps

and cable.

Motor Cable Grounding Test

Do not connect the pump control cable

to the control box or incoming voltage

before verifying the pump ground;

otherwise, personnel will be exposed to

serious injury or death.

Connect one lead of lamp, bell or similar testing de-

vice to motor cable green/yellow ground lead.

Connect second test lead to an

uninsulated

point

on the pump body. The test circuit should close.

If the test circuit does not close there is a defect in

the cable or motor which must be corrected.

Conductor Identification

The conductors in the pump cable are labeled

when shipped from the factory. If the conductors

are shortened in the field, resulting in loss of identi-

fication markers, they can still be identified by their

location relative to the ground wire.

Refer to FIGURE B−1; as seen from the free end of

the cable, the conductor immediately adjacent to

and clockwise from ground (green/yellow) is as-

signed number T1. The second clockwise conduc-

tor is T2, etc.

The conductors labeled P1 and P2 are for thermal

and moisture sensor connections, respectively.

If the conductors are relabled, they should be iden-

tified with wire markers from the factory.

Wiring Diagram and Control Box Connections

The pump warranty is void if the motor is

not operated through a control box ap-

proved by Gorman-Rupp.

This pump is shipped completely wired for the volt-

age shown on the nameplate, and is ready for op-

eration through an approved control box.

Ground the control box in accordance with the in-

structions accompanying it.

Refer to FIGURE B−1, and wire the motor to a con-

trol which will provide the connections shown.

Control leads P1 and P2 provide the motor with

moisture and thermal protection. Note that thermal

protection is supplementary

only

; separate Class

10 overload relays are required for motor running

protection.

The thermal protection contacts will auto-

matically reclose when the motor cools to

the established safe operating tempera-

ture. Whenever automatic restarting is not

desirable, connect only to controls which

are wired for manual restart.