-

304 SS

COUPLING, 1/4" NPT, PUSH-TO-DISCONNECT

2616751

1

84

-

VALVE, 1/4", BALL, THD, APOLLO

2610187

1

83

-

304 SS

NIPPLE CLOSE 1/4 NPT

2606875

1

82

-

302 SS

CLAMP, LOOP, CUSHIONED, 2 1/2" O.D.

9107150D7098

3

81

-

PLASTIC

COVER, UNISTRUT CHANNEL, 120" LG.

9107150D7082

3

80

-

-

CORDSET, 8P, SINGLE FEMALE, 30' LG.

2615298-30

4

79

Y

GALVANIZED

UNISTRUT CHANNEL, 1 5/8" x 3 1/4" x 76.00" LG.

9107150D7091

1

78

Y

GALVANIZED

UNISTRUT CHANNEL, 1 5/8" x 3 1/4" x 64.75" LG.

9107150D7090

1

77

Y

GALVANIZED

UNISTRUT CHANNEL, 1 5/8" x 3 1/4" x 36.75" LG.

9107150D7089

1

76

Y

GALVANIZED

UNISTRUT CHANNEL, 1 5/8" x 3 1/4" x 39" LG.

9107150D7088

1

75

Y

GALVANIZED

UNISTRUT CHANNEL, 1 5/8" x 3 1/4" x 39" LG.

9107150D7087

1

74

Silicone

GROMMET, 1" ID

2611835

18

73

Y

GALVANIZED

UNISTRUT CHANNEL, 1 5/8" x 3 1/4" x 18" LG.

9107150D7086

1

72

-

316 SS

HHCS, 1/4-20 X 0.75"

2603784

26

71

Y

GALVANIZED

UNISTRUT CHANNEL, 1 5/8" x 3 1/4" x 39" LG.

9107150D7085

1

70

Y

GALVANIZED

UNISTRUT CHANNEL, 1 5/8" x 3 1/4" x 45" LG.

9107150D7084

1

69

Y

PLASTIC

VALVE TAG SET - MEMBRANE FEED SKID

9107150D7004

1

68

-

-

WIRE, 10GA., 19STR, 600V, THHN, GREEN

2612662

10 FT.

67

-

-

WIRE, 10 GA., 19STR, 600V, THHN, BLACK

2612661

20 FT.

66

-

PVC

FLEX CONDUIT, PVC, 1", BLACK

2612061

1

65

-

NYLON

CONNECTOR, STRAIGHT, FLEX CONDUIT, 1"

2612060

1

64

-

316 SS

NUT, HEX, JAM, 1/4-20

2603011

3

63

-

316 SS

NUT, HEX, FULL, 1/4-20

2600476

3

62

-

316 SS

WASHER, FLAT, 1/4" X 5/8" X .044"

2600224

32

61

-

316 SS

HHCS, 1/4-20 X 1"

2600230

3

60

-

-

ELECTRIC DISCONNECT, 30A, NEMA 3R

2752673

1

59

-

-

DIN CONNECTOR, FEMALE, MOLEX C18311N21

2752632

3

58

-

-

CABLE, ELECTRIC, #16-3 COND., COLEMAN #22326

2616644

50 FT.

57

-

-

CORDGRIP, 0.169 - 0.499, 1/2" NPT

2607535

2

56

-

-

CABLE, SHIELDED TWISTED PAIR, BELDEN 3088AE

2752629

60 FT.

55

-

-

CORDSET, 8P, SINGLE FEMALE, 12' LG.

2613477

2

54

-

304 SS

HHCS, 5/8-11 X 3.75"

2603809

16

53

-

Cast Iron

FLOWMETER, KROHNE 4"

2613852

1

52

-

316 SS

RING, 4" KROHNE GROUNDING

2612312

2

51

Y

Default

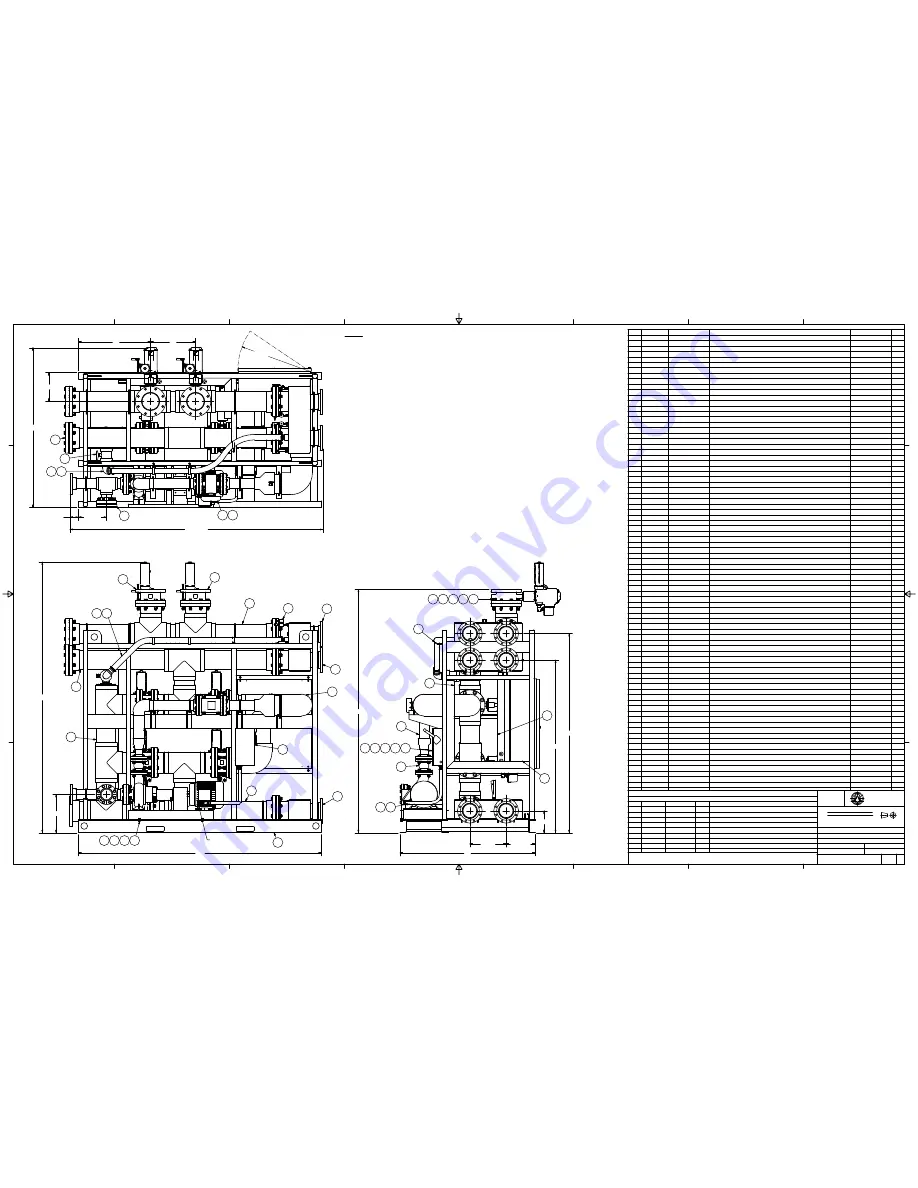

ASSEMBLY, PIPING, 4", PUMP DISCHARGE

9107150D7041

1

50

-

NYLON

CONNECTOR, 90DEG, FLEX CONDUIT, 1"

2616708

1

49

Y

Default

VALVE ASSY, SOLENOID, 1/4", VENT

2966645

2

48

-

304 SS

PIPE PLUG, 1/2" NPT, SQ. HD.

2609577

2

47

-

316L SS

TRANSDUCER, PRESSURE, 0-50 PSI, 1/4" NPT

2616711

3

46

304 SS

BUSHING- REDUCER 1/2 MPT TO 1/4 F

2613580

6

45

-

Stainless Steel

HOSE CLAMP - SS 1.875 - 2.75 DIA

2603278

2

44

-

EPDM

HOSE, 2" I.D. x 2.4" O.D.

2614329

1

43

-

PVC-Piping

COMBO NIPPLE, 2" HOSE X 2" NPT

2606497

1

42

-

PVC-Piping

ELBOW, 2", 90 DEG, S80, THD

2602924

1

41

-

PVC

NIPPLE, 2", S80, TBE X 2.50"

2608322

1

40

-

PVC-Piping

VALVE, 2" BALL TRU-UNION

2603299

1

39

-

316 SS

HHCS, 3/8-16 X 1.25"

2602257

4

38

Y

304 SS

U-BOLT, 3/8-16, 4"

2609950

4

37

-

316 SS

HHCS, 3/8-16 X 1.5"

2600421

4

36

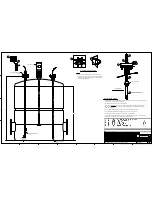

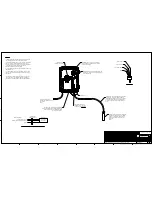

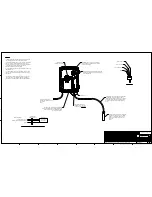

Y

-

INSTL, CONTROL PANEL, FEED SKID

9107150D7703

1

35

Y

304 SS

U-BOLT, 3/8"-16 X 8" PIPE

2609993

12

34

-

316 SS

NUT, HEX, JAM, 3/8-16

2600403

52

33

-

316 SS

NUT, HEX, FULL, 3/8-16

2600481

52

32

-

316 SS

WASHER, FLAT, 3/8" X 1" X .042"

2600381

60

31

Y

304 SS

U-BOLT, 3/8"-16 X 6" PIPE

2609992

6

30

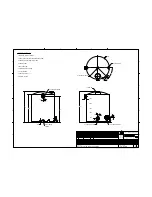

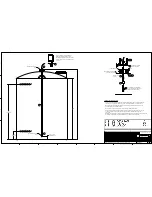

Y

304 SS

WELDMENT, SPLITTER BOX, FILTRATE

2915801-SF0

1

29

Y

304 SS

WELDMENT, SPLITTER BOX, FEED

2915800-SF0

2

28

-

304 SS

HHCS, 5/8-11 X 4.00"

2607274

8

27

Y

-

VALVE ASSY, 8" B/FLY 511A TO SG10.1 ACT MI-AM

2966227-4

2

26

Y

-

VALVE ASSY, 8" B/FLY 511A TO SG10.1 ACT MI-AM

2966227-2

2

25

Y

-

VALVE ASSY, 8" B/FLY 511A TO SG10.1 ACT MI-AM

2966227-3

2

24

-

316 SS

NUT, HEX, JAM, 5/8-11

2600302

40

23

-

316 SS

NUT, HEX, FULL, 5/8-11

2600301

40

22

-

316 SS

HHCS, 5/8-11 X 3.5"

2602344

16

21

-

316 SS

WASHER, FLAT, 5/8" X 1 1/4"

2602498

80

20

Y

PVC

ASSEMBLY, PIPING, FEED, 8"

9107150D7042

1

19

-

304 SS

HHCS, 3/4-10 X 7.50"

2612010

8

18

-

PVC

VALVE, B/FLY, PVC, MANUAL, 8"

2616707

1

17

Y

PVC

ASSEMBLY, PIPING, BOTTOM FEED, 8"

9107150D7040

1

16

Y

PVC

ASSEMBLY, PIPING, DRAIN, 8"

9107150D7037

1

15

-

304 SS

EXPANSION JOINT, 3", 150#, METRASPHERE

2616073

1

14

-

304 SS

HHCS, 3/4-10 X 4.5"

2605196

120

13

-

PVC

FLANGE, BLIND, 8", 150#

2611241

2

12

Y

PVC

ASSEMBLY, PIPING, TOP FEED, 8"

9107150D7038

1

11

-

316 SS

NUT, HEX, JAM, 3/4-10

2602579

128

10

-

316 SS

NUT, HEX, FULL, 3/4-10

2600496

128

9

-

316 SS

WASHER, FLAT, 3/4" X 1 7/8"

2602580

256

8

Y

EPDM

GASKET, FULL FACE, 150#, 8"

2510129

18

7

-

PVC-Piping

BLIND FLANGE, 4" S80, PVC

2606568

1

6

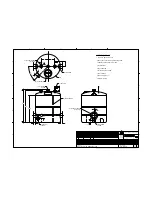

Y

PVC

ASSEMBLY, PIPING, PUMP INLET, 4"

9107150D7036

1

5

Y

EPDM

GASKET, FULL FACE, 150#, 4"

2607946

6

4

Y

-

ASSEMBLY, PUMP, G-R VG3B3-B, 7.5 HP

2967012

1

3

Y

PVC

ASSEMBLY, PIPING, FILTRATE, 8"

9107150D7035

1

2

Y

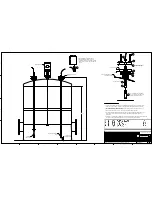

MILD STEEL

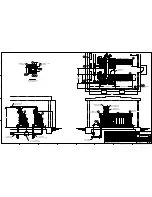

WELDMENT, FRAME, FEED SKID

9107150D7009

1

1

DWG

MATERIAL

DESCRIPTION

PART NUMBER

QTY

ITEM

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

A

A

B

B

C

C

D

D

ASSEMBLY, MEMBRANE FEED SKID

COPYRIGHT 2013 AQUA-AEROBIC SYSTEMS, INC. ALL RIGHTS RESERVED. THIS DRAWING MAY NOT BE COPIED ALL OR IN PART WITHOUT THE EXPRESS WRITTEN PERMISSION OF AQUA-AEROBIC SYSTEMS, INC.

ANSI

D

JOB NAME:

JOB LOCATION:

DRAWING NAME:

DRAWING NUMBER:

WEIGHT:

TYPE:

SIMILAR TO:

MATERIAL:

SHEET:

OF

SIZE:

SCALE:

9107150D7001

4200

1/12

AUGUSTA CORRECTIONAL FACILITY

CRAIGSVILLE, VIRGINIA

DRAWN BY:

DATE:

GML

2013-11-14

LBS

UNLESS OTHERWISE SPECIFIED

ALL DIMENSIONS ARE IN INCHES

DO NOT

SCALE

DRAWING

AQUA-AEROBIC

SYSTEMS, INC.

+/- 1/16

+/- 0.010

+/- 0.005

+/- 1/2

FRACTIONAL DIMENSIONS

ALL TWO PLACE DECIMALS

ALL THREE PLACE DECIMALS

ALL ANGLES

1

2

A

2013-11-25

GML SUBMITTAL RELEASE

B

R14425

2014-04-02

GML RELEASE TO PRODUCTION

REV

ERN/ECO

DATE

BY

REVISION DESCRIPTION

NOTES:

1. FRAME WELDMENT (ITEM #1) IS TO BE FINISH PAINTED PER AQUA-AEROBIC SYSTEMS' ENGINEERING

STANDARD #ES-1058 PRIOR TO ASSEMBLY.

2. REMOVE ALL BURRS AND BREAK ALL SHARP EDGES.

3. ANTI-SEIZE LUBRICANT IS REQUIRED ON ALL STAINLESS STEEL FASTENERS, UNLESS OTHERWISE SPECIFIED.

4. INSIDE AND OUTSIDE OF ALL PIPING MUST BE FREE OF EXCESS SOLVENT CEMENT. EXCESS SOLVENT CEMENT

MUST BE COMPLETELY REMOVED AND THE SURFACE CLEAN.

5. 12 FT. LONG CORDSETS (ITEM #54) ARE TO BE USED FOR WIRING THE TOP AND BOTTOM FEED VALVES TO THE

CONTROL PANEL. 30 FT. CORDSETS (ITEM #79) ARE USED FOR WIRING THE REMAINING VALVES TO THE

CONTROL PANEL.

6. SHIELDED CABLE (ITEM #55), CORDGRIP (ITEM #56) AND #16-3 CONDUCTOR ELECTRIC CABLE (ITEM #57) ARE

TO BE USED FOR WIRING TO THE FLOW METER (ITEM #52).

7. #16-3 CONDUCTOR ELECTRIC CABLE (ITEM #57) AND DIN CONNECTOR (ITEM #58) ARE USED FOR WIRING TO

THE SOLENOID VALVES (ITEM #48) MOUNTED ON THE SPLITTER BOXES.

8. 90 DEGREE CONDUIT CONNECTOR (ITEM #49) IS TO BE USED AT THE PUMP MOTOR JUNCTION BOX. STRAIGHT

CONDUIT CONNECTOR (ITEM #64) IS TO BE USED AT THE DISCONNECT BOX (ITEM #59).

9. USE 10 GA. WIRE (ITEM #66 AND #67) TO WIRE PUMP MOTOR TO DISCONNECT BOX (ITEM #59). BLACK WIRE

(ITEM #66) IS TO BE USED FOR THE MOTOR WINDINGS. GREEN WIRE (ITEM #67) IS TO BE USED AS THE GROUND

WIRE.

10. SHIELDED CABLE (ITEM #55) WILL BE USED FOR WIRING TO THE PRESSURE TRANSMITTERS (ITEM #46)

MOUNTED ON THE SPLITTER BOXES.

NOTE:

THE PRESSURE TRANSMITTER (ITEM #46) IS SUPPLIED WITH THE MATING MALE CONNECTOR.

11. HOLES FOR MOUNTING THE UNISTRUT CHANNELS TO THE FRAME ARE TO BE DRILLED AND TAPPED AT ASSEMBLY.

USE 1/4"-20 UNC BOLTS (ITEM #71) AND 1/4" WASHERS (ITEM #61) FOR ATTACHING UNISTRUT. CUT CHANNEL

COVER (ITEM #80) AS NECESSARY AND INSTALL AFTER ROUTING ELECTRIC CABLES.

NOTE:

WHEN ROUTING POWER CABLES AND SIGNAL CABLES THROUGH THE SAME CHANNEL A DIVIDER MUST

BE USED TO KEEP THE POWER CABLES SEPARATED FROM THE SIGNAL CABLE.

16 1/8

9 3/4

76 3/4

88 1/2

108

60

12 13/16

32

20

12 13/16

108 3/16

(120 5/16)

24

24

2

29

28

28

14

50

19

16

15

1

11

76

75

70

DS-122

/

DS-142

FEED PUMP MOTOR

MTR-122 / MTR-142

(112 5/16)

(3 13/16)

(71 1/16)

12 7/16

17

R32 5/16

13

7

8

9

10

48

43

43

44

59

65

49

59

60

61

62

63

38

31

32

33

12

6

52

51

39

41

42

Summary of Contents for VG3B3-B

Page 14: ...GENERAL INFORMATION...

Page 17: ...EQUIPMENT SAFETY DOCUMENTS and PRECAUTIONS...

Page 30: ...U L MOTOR REQUIREMENTS...

Page 31: ......

Page 35: ...PROTECTIVE COATINGS...

Page 37: ...PAINT TECHNICAL DATA SHEETS...

Page 43: ...PASSIVATION DOCUMENTS...

Page 47: ...STORAGE PROCEDURES...

Page 51: ...INSTRUMENTATION...

Page 56: ...VALVES...

Page 58: ...PUMPS...

Page 61: ...MATERIAL SAFETY DATA SHEETS...

Page 65: ......

Page 66: ...PAINT COATING MSDS...

Page 73: ...ADHESIVE ANCHORS MSDS...

Page 74: ...SIMPSON...

Page 95: ......

Page 96: ......

Page 97: ......

Page 98: ......

Page 99: ......

Page 100: ...INSTALLATION AND START UP...

Page 103: ...START UP PAPERS...

Page 125: ...PROCESS AND CONTROL...

Page 181: ...MECHANICAL AND FIELD INSTRUMENT COMPONENT INFORMATION...

Page 182: ...ACTUATOR...

Page 183: ...CORD SET...

Page 185: ...AUMA...

Page 186: ...115V 1ph 60Hz...

Page 190: ...ANCHORS...

Page 191: ...ADHESIVE ANCHOR See Drawing Section 7 for Details...

Page 192: ...MANUAL GUN...

Page 194: ...REFILL PACK...

Page 197: ...MIXING NOZZLE...

Page 199: ...INSTRUMENTATION...

Page 200: ...CONTROLLER...

Page 201: ...THERMO FISHER...

Page 203: ...pH PROBE...

Page 206: ...FLOW METER...

Page 211: ...PRESSURE TRANSMITTER...

Page 213: ...PUMP...

Page 214: ...MEMBRANE FEED PUMP...

Page 217: ...Pump Part 2616713 Gorman Rupp VG3B3 B Centrifugal 2013 12 09 2616713 Pump doc 3 of 3...

Page 220: ...BACKWASH PUMP...

Page 223: ...Pump Part 2616695 Gorman Rupp VG3C3 B Centrifugal 2013 12 09 2616695 Pump doc 3 of 3...

Page 227: ...BUTTERFLY VALVE...

Page 228: ...MANUAL LEVER BUTTERFLY VALVE...

Page 238: ...ELECTRIC BUTTERFLY VALVE...

Page 241: ...SWING CHECK VALVE...

Page 243: ...SOLENOID VALVE...

Page 245: ...MEMBRANE MODULE ACCESSORIES...

Page 254: ...AIR COMPRESSOR ACCESSORIES...

Page 258: ...ELECTRICAL CONTROL PANEL COMPONENT INFORMATION...

Page 265: ...CABLE CONDUIT WIRE...

Page 271: ...CIRCUIT BREAKER...

Page 281: ...COMPUTER and MONITOR...

Page 289: ...ENCLOSURE...

Page 296: ...ENCLOSURE ACCESSORIES...

Page 307: ...ENVIRONMENTAL CONTROL ENCLOSURE...

Page 314: ...FUSE...

Page 329: ...FUSE BLOCK...

Page 336: ...HMI HUMAN MACHINE INTERFACE...

Page 343: ...MAIN DISCONNECT...

Page 350: ...MAIN DISCONNECT ACCESSORIES...

Page 354: ...MOTOR CONTROL...

Page 368: ...NETWORK...

Page 379: ...PILOT DEVICE...

Page 392: ...PLC PROGRAMMABLE LOGIC CONTROL...

Page 420: ...PRINTERS...

Page 424: ...POWER SUPPLY...

Page 426: ...Power Supply Part 2751312 Allen Bradley 2008 02 28 2751312 AB Power Supply doc 2 of 5...

Page 427: ...Power Supply Part 2751312 Allen Bradley 2008 02 28 2751312 AB Power Supply doc 3 of 5...

Page 428: ...Power Supply Part 2751312 Allen Bradley 2008 02 28 2751312 AB Power Supply doc 4 of 5...

Page 429: ...Power Supply Part 2751312 Allen Bradley 2008 02 28 2751312 AB Power Supply doc 5 of 5...

Page 434: ...RELAY CONTROL...

Page 440: ...SURGE SUPPRESSOR TRANSIENT FILTER...

Page 447: ...TERMINAL BLOCK ACCESSORIES...

Page 471: ...TIMERS...

Page 477: ...TRANSFORMER ACCESSORIES...

Page 482: ...UPS UNINTERRUPTIBLE POWER SUPPLY...

Page 489: ...MAINTENANCE AND TROUBLESHOOTING...

Page 498: ...COMPONENT PRODUCTS EQUIPMENT O M INSTRUCTION MANUALS...

Page 499: ...ACTUATOR...

Page 500: ...ELECTRIC...

Page 534: ...ADHESIVE ANCHOR O M...

Page 535: ......

Page 537: ...INSTRUMENTATION O M...

Page 538: ...FLOW METER...

Page 684: ...5 NOTES 30 IFC 100 www krohne com 07 2010 4000124104 QS IFC 100 R04 en...

Page 685: ...NOTES 5 31 IFC 100 www krohne com 07 2010 4000124104 QS IFC 100 R04 en...

Page 687: ......

Page 688: ......

Page 689: ......

Page 690: ......

Page 691: ......

Page 692: ......

Page 693: ......

Page 694: ......

Page 695: ......

Page 696: ......

Page 697: ......

Page 698: ......

Page 699: ......

Page 700: ......

Page 701: ......

Page 702: ......

Page 703: ......

Page 704: ......

Page 705: ......

Page 706: ......

Page 707: ......

Page 708: ......

Page 709: ......

Page 710: ......

Page 711: ......

Page 712: ......

Page 713: ......

Page 714: ......

Page 715: ......

Page 716: ......

Page 717: ......

Page 718: ......

Page 719: ......

Page 720: ......

Page 721: ......

Page 722: ......

Page 723: ...TURBIDITY MONITORING O M...

Page 734: ...10 Installation Figure 4 1720E Dimensions...

Page 738: ...14 System Startup...

Page 746: ...22 Operation...

Page 754: ...30 Troubleshooting...

Page 760: ...36 Modbus Register Information...

Page 762: ...38 Index...

Page 763: ...DOC023 53 80221 FT660 sc 01 2012 Edition 2 User Manual...

Page 764: ......

Page 782: ...1 2 18 English...

Page 783: ...3 4 English 19...

Page 790: ...26 English...

Page 791: ......

Page 793: ...CONTROLLER...

Page 794: ...Thermo Scientific AquaSensors AV38 Local Display and Controller User Guide...

Page 873: ......

Page 875: ...pH PROBE...

Page 880: ...PRESSURE TRANSMITTER...

Page 881: ......

Page 900: ...A 9 Keller America Inc User s Guide Rev 10 11...

Page 901: ...A 10 Keller America Inc User s Guide Rev 10 11...

Page 904: ...MEMBRANE MODULE...

Page 905: ...inge GmbH Installation Operation and Maintenance Guidelines inge T Rack vario...

Page 934: ......

Page 935: ...Appendix B Process Specification inge UF...

Page 957: ...PUMPS...

Page 958: ...GORMAN RUPP PUMP...

Page 959: ......

Page 960: ......

Page 961: ......

Page 962: ......

Page 963: ......

Page 964: ......

Page 965: ......

Page 966: ......

Page 967: ......

Page 968: ......

Page 969: ......

Page 970: ......

Page 971: ......

Page 972: ......

Page 973: ......

Page 974: ......

Page 975: ......

Page 976: ......

Page 977: ......

Page 978: ......

Page 979: ......

Page 980: ......

Page 981: ......

Page 982: ......

Page 983: ......

Page 984: ......

Page 985: ......

Page 986: ......

Page 987: ......

Page 988: ......

Page 989: ......

Page 990: ......

Page 991: ......

Page 1056: ...VALVES...

Page 1057: ...NIBCO VALVE...

Page 1058: ...WAFER BUTTERFLY VALVE...

Page 1068: ...MILLIKEN VALVE...

Page 1069: ...MILLIKEN BUTTERFLY VALVE...

Page 1070: ......

Page 1077: ...MECHANICAL DRAWINGS...

Page 1110: ...ELECTRICAL DRAWINGS...

Page 1119: ......

Page 1153: ......

Page 1157: ......