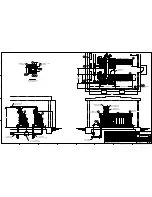

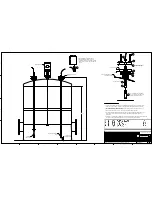

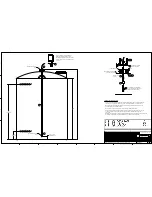

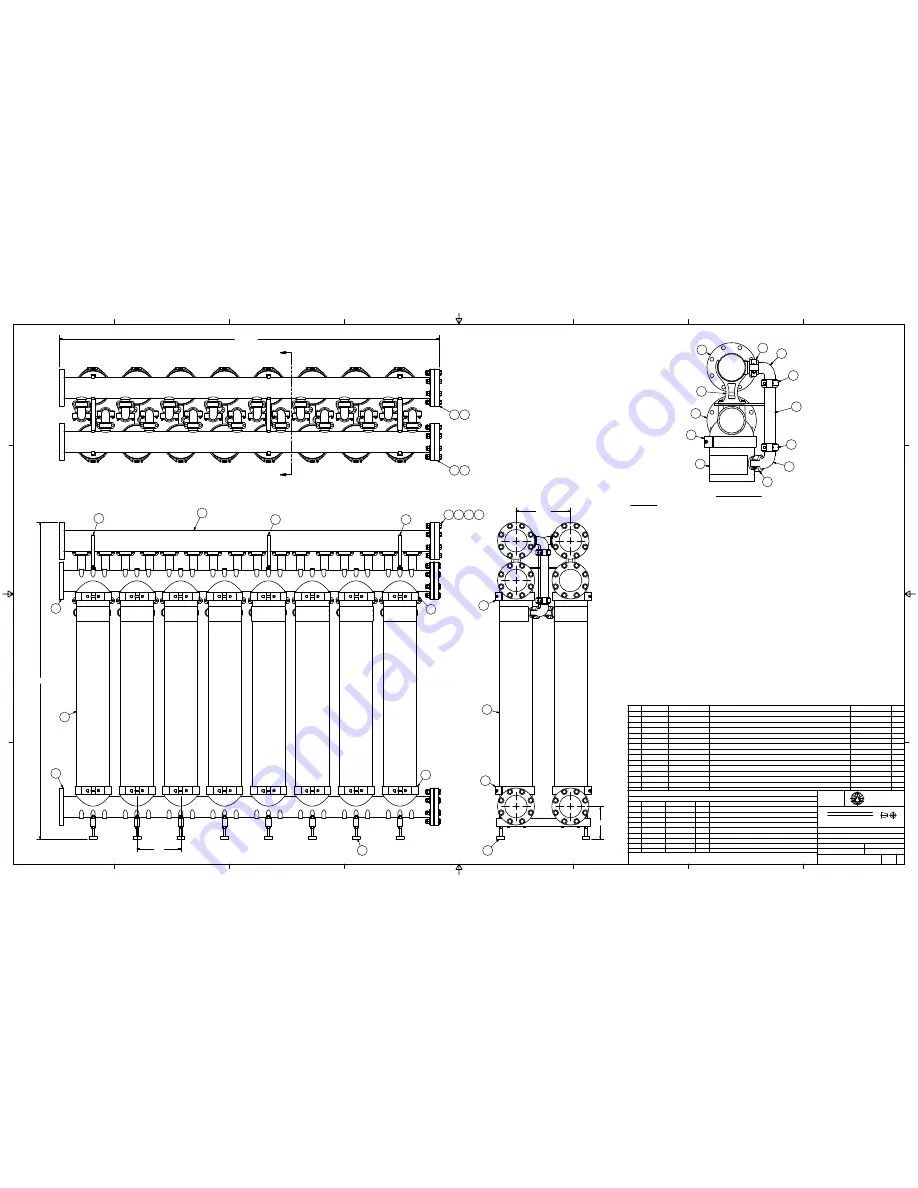

SECTION A-A

-

316 SS

NUT, HEX, JAM, 3/4-10

2602579

48

15

-

316 SS

NUT, HEX, FULL, 3/4-10

2600496

48

14

-

316 SS

HHCS, 3/4-10 X 4"

2607490

48

13

-

316 SS

WASHER, FLAT, 3/4" X 1 7/8"

2602580

96

12

-

PVC

FLANGE, 6", S80, BLIND

2606356

6

11

Y

EPDM

GASKET, FULL FACE, 150#, 6"

2510128

6

10

-

PLASTIC

COUPLING, FLEXIBLE, GROOVED, 2"

2616434

64

9

-

PVC

PIPE, FILTRATE, 2", TRANSPARENT

2616433

16

8

-

-

ELBOW, 90DEG, 2", GROOVED END

2616435

32

7

-

PVC-U

HEADER, FILTRATE, 160 mm, 8-MODULE

2616440-08

2

6

-

-

CROSS BRACE, TOP, FILTRATE HEADER

2616438

3

5

-

Stainless Steel

COUPLING, INGE ULTRA S 250

2616436

32

4

-

-

ASSEMBLY, MEMBRANE MODULE, DIZZER XL 0.9 MB 60 WT

2966907

16

3

-

-

CROSS BRACE, BOTTOM, MODULES

2616439

8

2

-

PVC-U

HEADER, FEED / DRAIN, 6", MEMBRANE, 8-MODULE

2616437-08

4

1

DWG

MATERIAL

DESCRIPTION

PART NUMBER

QTY

ITEM

A

A

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

A

A

B

B

C

C

D

D

ASSEMBLY, T-RACK, 16-MODULE

COPYRIGHT 2013 AQUA-AEROBIC SYSTEMS, INC. ALL RIGHTS RESERVED. THIS DRAWING MAY NOT BE COPIED ALL OR IN PART WITHOUT THE EXPRESS WRITTEN PERMISSION OF AQUA-AEROBIC SYSTEMS, INC.

ANSI

D

JOB NAME:

JOB LOCATION:

DRAWING NAME:

DRAWING NUMBER:

WEIGHT:

TYPE:

SIMILAR TO:

MATERIAL:

SHEET:

OF

SIZE:

SCALE:

9107150D7002

-

2800#

1/8

AUGUSTA CORRECTIONAL FACILITY

CRAIGSVILLE, VIRGINIA

DRAWN BY:

DATE:

GML

2013-11-15

(WET)

UNLESS OTHERWISE SPECIFIED

ALL DIMENSIONS ARE IN INCHES

DO NOT

SCALE

DRAWING

AQUA-AEROBIC

SYSTEMS, INC.

+/- 1/16

+/- 0.010

+/- 0.005

+/- 1/2

FRACTIONAL DIMENSIONS

ALL TWO PLACE DECIMALS

ALL THREE PLACE DECIMALS

ALL ANGLES

1

1

A

2013-11-15

GML SUBMITTAL RELEASE

B

R14425

2014-04-02

GML RELEASE TO PRODUCTION

REV

ERN/ECO

DATE

BY

REVISION DESCRIPTION

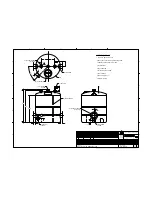

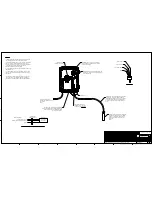

NOTES:

1. REVIEW ALL INSTALLATION AND ASSEMBLY DRAWINGS AND INSTRUCTIONS IN THE OPERATION AND

MAINTENANCE MANUAL PRIOR TO INSTALLING THE EQUIPMENT.

2. ANTI-SEIZE LUBRICANT IS REQUIRED ON ALL STAINLESS STEEL FASTENERS, UNLESS OTHERWISE

SPECIFIED.

3. ASSEMBLE THE BOTTOM CROSS BRACE SUPPORTS (ITEM #2) TO THE FEED / DRAIN HEADERS (ITEM #1).

4. REMOVE PROTECTIVE SHIPPING CAPS FROM MODULES (ITEM #3) PRIOR TO ASSEMBLING TO FEED

HEADER (ITEM #1).

NOTE:

MODULES ARE SHIPPED SATURATED WITH A NON-HAZARDOUS SOLUTION OF WATER, GLYCERIN,

AND SODIUM BISULFITE. ALLOW ANY EXCESS SOLUTION TO DRAIN FROM MODULES INTO A

CONTAINER FOR LATER DISPOSAL.

SET MODULE (ITEM #3) AND COUPLING (ITEM #4) IN PLACE ON THE FEED / DRAIN HEADER (ITEM #1), BUT

DO NOT SECURE MODULE IN PLACE. MODULE MUST BE ALLOWED TO ROTATE FOR ALIGNMENT OF FILTRATE

PIPE FITTINGS.

5. ATTACH FEED / DRAIN HEADER (ITEM #1) TO THE TOP OF THE MODULES (ITEM #3). ATTACH TOP CROSS

BRACE SUPPORT (ITEM #5) TO THE TOP OF THE FEED / DRAIN HEADER (ITEM #1).

6. PLACE FILTRATE HEADER (ITEM #6) INTO TOP CROSS BRACE (ITEM #5).

NOTE:

MAKE CERTAIN THAT THE FILTRATE CONNECTIONS ON HEADERS THAT ARE PARALLEL TO EACH

OTHER ARE OFFSET FROM EACH OTHER. THIS CAN BE ACCOMPLISHED BY TURNING ONE HEADER

END-TO-END FROM THE OTHER.

7. CONNECT FILTRATE HEADER (ITEM #6) TO THE FILTRATE CONNECTION OF THE MODULE (ITEM #3) USING

2" ELBOWS, CLEAR PVC PIPE, AND COUPLINGS. ONCE THE FILTRATE CONNECTION HAS BEEN MADE, THE

MODULES (ITEM #3) MAY BE SECURED IN PLACE BY TIGHTENING THE COUPLINGS (ITEM #4) AT EACH END.

8. INSTALL GASKET (ITEM #10) AND BLIND FLANGE (ITEM #11) TO THE END OF THE ASSEMBLY NOT CONNECTED

TO THE FEED SKID.

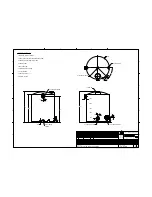

9 11/16

16 1/8

(112 9/16)

(13)

(93 15/16)

6

1

3

4

5

9

7

9

8

9

7

9

5

5

5

6

1

1

3

4

4

3

4

4

2

2

11

10

11

10

13

12

14

15

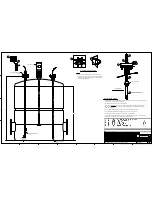

Summary of Contents for VG3B3-B

Page 14: ...GENERAL INFORMATION...

Page 17: ...EQUIPMENT SAFETY DOCUMENTS and PRECAUTIONS...

Page 30: ...U L MOTOR REQUIREMENTS...

Page 31: ......

Page 35: ...PROTECTIVE COATINGS...

Page 37: ...PAINT TECHNICAL DATA SHEETS...

Page 43: ...PASSIVATION DOCUMENTS...

Page 47: ...STORAGE PROCEDURES...

Page 51: ...INSTRUMENTATION...

Page 56: ...VALVES...

Page 58: ...PUMPS...

Page 61: ...MATERIAL SAFETY DATA SHEETS...

Page 65: ......

Page 66: ...PAINT COATING MSDS...

Page 73: ...ADHESIVE ANCHORS MSDS...

Page 74: ...SIMPSON...

Page 95: ......

Page 96: ......

Page 97: ......

Page 98: ......

Page 99: ......

Page 100: ...INSTALLATION AND START UP...

Page 103: ...START UP PAPERS...

Page 125: ...PROCESS AND CONTROL...

Page 181: ...MECHANICAL AND FIELD INSTRUMENT COMPONENT INFORMATION...

Page 182: ...ACTUATOR...

Page 183: ...CORD SET...

Page 185: ...AUMA...

Page 186: ...115V 1ph 60Hz...

Page 190: ...ANCHORS...

Page 191: ...ADHESIVE ANCHOR See Drawing Section 7 for Details...

Page 192: ...MANUAL GUN...

Page 194: ...REFILL PACK...

Page 197: ...MIXING NOZZLE...

Page 199: ...INSTRUMENTATION...

Page 200: ...CONTROLLER...

Page 201: ...THERMO FISHER...

Page 203: ...pH PROBE...

Page 206: ...FLOW METER...

Page 211: ...PRESSURE TRANSMITTER...

Page 213: ...PUMP...

Page 214: ...MEMBRANE FEED PUMP...

Page 217: ...Pump Part 2616713 Gorman Rupp VG3B3 B Centrifugal 2013 12 09 2616713 Pump doc 3 of 3...

Page 220: ...BACKWASH PUMP...

Page 223: ...Pump Part 2616695 Gorman Rupp VG3C3 B Centrifugal 2013 12 09 2616695 Pump doc 3 of 3...

Page 227: ...BUTTERFLY VALVE...

Page 228: ...MANUAL LEVER BUTTERFLY VALVE...

Page 238: ...ELECTRIC BUTTERFLY VALVE...

Page 241: ...SWING CHECK VALVE...

Page 243: ...SOLENOID VALVE...

Page 245: ...MEMBRANE MODULE ACCESSORIES...

Page 254: ...AIR COMPRESSOR ACCESSORIES...

Page 258: ...ELECTRICAL CONTROL PANEL COMPONENT INFORMATION...

Page 265: ...CABLE CONDUIT WIRE...

Page 271: ...CIRCUIT BREAKER...

Page 281: ...COMPUTER and MONITOR...

Page 289: ...ENCLOSURE...

Page 296: ...ENCLOSURE ACCESSORIES...

Page 307: ...ENVIRONMENTAL CONTROL ENCLOSURE...

Page 314: ...FUSE...

Page 329: ...FUSE BLOCK...

Page 336: ...HMI HUMAN MACHINE INTERFACE...

Page 343: ...MAIN DISCONNECT...

Page 350: ...MAIN DISCONNECT ACCESSORIES...

Page 354: ...MOTOR CONTROL...

Page 368: ...NETWORK...

Page 379: ...PILOT DEVICE...

Page 392: ...PLC PROGRAMMABLE LOGIC CONTROL...

Page 420: ...PRINTERS...

Page 424: ...POWER SUPPLY...

Page 426: ...Power Supply Part 2751312 Allen Bradley 2008 02 28 2751312 AB Power Supply doc 2 of 5...

Page 427: ...Power Supply Part 2751312 Allen Bradley 2008 02 28 2751312 AB Power Supply doc 3 of 5...

Page 428: ...Power Supply Part 2751312 Allen Bradley 2008 02 28 2751312 AB Power Supply doc 4 of 5...

Page 429: ...Power Supply Part 2751312 Allen Bradley 2008 02 28 2751312 AB Power Supply doc 5 of 5...

Page 434: ...RELAY CONTROL...

Page 440: ...SURGE SUPPRESSOR TRANSIENT FILTER...

Page 447: ...TERMINAL BLOCK ACCESSORIES...

Page 471: ...TIMERS...

Page 477: ...TRANSFORMER ACCESSORIES...

Page 482: ...UPS UNINTERRUPTIBLE POWER SUPPLY...

Page 489: ...MAINTENANCE AND TROUBLESHOOTING...

Page 498: ...COMPONENT PRODUCTS EQUIPMENT O M INSTRUCTION MANUALS...

Page 499: ...ACTUATOR...

Page 500: ...ELECTRIC...

Page 534: ...ADHESIVE ANCHOR O M...

Page 535: ......

Page 537: ...INSTRUMENTATION O M...

Page 538: ...FLOW METER...

Page 684: ...5 NOTES 30 IFC 100 www krohne com 07 2010 4000124104 QS IFC 100 R04 en...

Page 685: ...NOTES 5 31 IFC 100 www krohne com 07 2010 4000124104 QS IFC 100 R04 en...

Page 687: ......

Page 688: ......

Page 689: ......

Page 690: ......

Page 691: ......

Page 692: ......

Page 693: ......

Page 694: ......

Page 695: ......

Page 696: ......

Page 697: ......

Page 698: ......

Page 699: ......

Page 700: ......

Page 701: ......

Page 702: ......

Page 703: ......

Page 704: ......

Page 705: ......

Page 706: ......

Page 707: ......

Page 708: ......

Page 709: ......

Page 710: ......

Page 711: ......

Page 712: ......

Page 713: ......

Page 714: ......

Page 715: ......

Page 716: ......

Page 717: ......

Page 718: ......

Page 719: ......

Page 720: ......

Page 721: ......

Page 722: ......

Page 723: ...TURBIDITY MONITORING O M...

Page 734: ...10 Installation Figure 4 1720E Dimensions...

Page 738: ...14 System Startup...

Page 746: ...22 Operation...

Page 754: ...30 Troubleshooting...

Page 760: ...36 Modbus Register Information...

Page 762: ...38 Index...

Page 763: ...DOC023 53 80221 FT660 sc 01 2012 Edition 2 User Manual...

Page 764: ......

Page 782: ...1 2 18 English...

Page 783: ...3 4 English 19...

Page 790: ...26 English...

Page 791: ......

Page 793: ...CONTROLLER...

Page 794: ...Thermo Scientific AquaSensors AV38 Local Display and Controller User Guide...

Page 873: ......

Page 875: ...pH PROBE...

Page 880: ...PRESSURE TRANSMITTER...

Page 881: ......

Page 900: ...A 9 Keller America Inc User s Guide Rev 10 11...

Page 901: ...A 10 Keller America Inc User s Guide Rev 10 11...

Page 904: ...MEMBRANE MODULE...

Page 905: ...inge GmbH Installation Operation and Maintenance Guidelines inge T Rack vario...

Page 934: ......

Page 935: ...Appendix B Process Specification inge UF...

Page 957: ...PUMPS...

Page 958: ...GORMAN RUPP PUMP...

Page 959: ......

Page 960: ......

Page 961: ......

Page 962: ......

Page 963: ......

Page 964: ......

Page 965: ......

Page 966: ......

Page 967: ......

Page 968: ......

Page 969: ......

Page 970: ......

Page 971: ......

Page 972: ......

Page 973: ......

Page 974: ......

Page 975: ......

Page 976: ......

Page 977: ......

Page 978: ......

Page 979: ......

Page 980: ......

Page 981: ......

Page 982: ......

Page 983: ......

Page 984: ......

Page 985: ......

Page 986: ......

Page 987: ......

Page 988: ......

Page 989: ......

Page 990: ......

Page 991: ......

Page 1056: ...VALVES...

Page 1057: ...NIBCO VALVE...

Page 1058: ...WAFER BUTTERFLY VALVE...

Page 1068: ...MILLIKEN VALVE...

Page 1069: ...MILLIKEN BUTTERFLY VALVE...

Page 1070: ......

Page 1077: ...MECHANICAL DRAWINGS...

Page 1110: ...ELECTRICAL DRAWINGS...

Page 1119: ......

Page 1153: ......

Page 1157: ......