OM-06114

VGH SERIES

PAGE B - 6

INSTALLATION

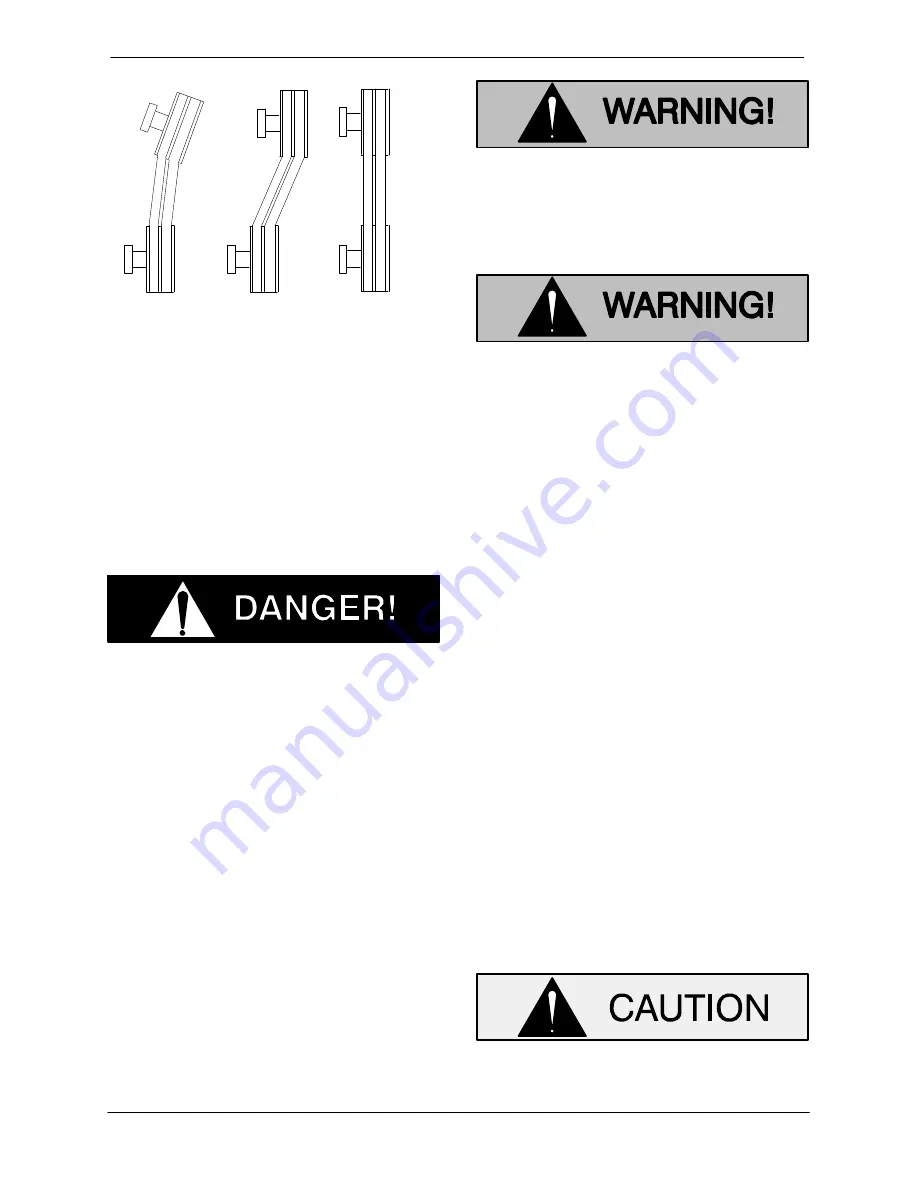

MISALIGNED:

SHAFTS

NOT PARALLEL

MISALIGNED:

SHAFTS

NOT IN LINE

ALIGNED: SHAFTS

PARALLEL AND

SHEAVES IN LINE

Figure 3C. Alignment of V‐Belt Driven Pumps

Tighten the belts in accordance with the belt manu

facturer's instructions. If the belts are too loose,

they will slip; if the belts are too tight, there will be

excessive power loss and possible bearing failure.

Select pulleys that will match the proper speed ra

tio; overspeeding the pump may damage both

pump and power source.

Do not operate the pump without the

guard in place over the rotating parts

.

exposed rotating parts can catch cloth

ing, fingers, or tools, causing severe in

jury to personnel.

ELECTRICAL CONNECTIONS

If the pump is driven by an electric motor, check

that the electrical service available matches the

motor requirements stamped on the motor name

plate before connecting a motor to the incoming

power. Check that the motor speed meets pump

specifications.

If rotation is incorrect on a three‐phase motor, have

a qualified electrician interchange any two of the

three phase wires to change direction. If rotation is

incorrect on a single‐phase motor, consult the lit

erature supplied with the motor for specific instruc

tions.

The electrical power used to operate the

pump is high enough to cause injury or

death. Obtain the services of a qualified

electrician to make all electrical con

nections.

If the pump is powered by an electric

motor, do not operate a non‐explosion

proof motor in an explosive atmo

sphere. An explosion, which may cause

severe personal injury or death, could

result. Install, connect and operate the

motor in accordance with the National

Electric Code and all local codes. If

there is a conflict between the instruc

tions in the manual accompanying the

unit and the National Electric Code or

applicable local code, the National or

Local code shall take precedence. All

electrical equipment supplied with the

pump conforms to applicable federal

regulations and national codes in effect

on the date of manufacture.

GROUNDING

If the pump has been approved to pump volatile or

flammable liquids, the unit must be grounded by

attaching the ground wire assembly to a ground

rod in order to eliminate electrostatic build‐up by

the liquid being pumped. Install the ground rod in

accordance with the National Electrical Codes and

all local codes. Be sure the fastening device makes

a tight electrical connection with the rod and the

pump.

Inspect and test the ground wire assembly

for conductivity. replace broken or frayed

wire before resuming operation.