Operators

manual

Gorter-Controls B.V. – Schoonhoven- The Netherlands

Operators manual underground gas pressure reducing station

Type: COCON 26 N-LP

Page 17

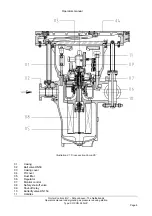

4.6.2 Installation of cartridge

This paragraph describes the installation of the cartridge in the casing. The cartridge can be replaced

with a spare cartridge (adjusted) within 20 minutes. The cartridge is positioned with a bayonet

coupling. The cartridge is locked by the influence block which prevents the cartridge to rotate in the

casing.

To install the cartridge in the casing, proceed as follows:

Remark:

Take care of your back, while the installation and removal of the cartridge.

Kneel and keep your back straight.

-

Lift the cartridge by the handles.

-

Lower the cartridge perpendicular in the casing.

-

Rotate the cartridge to the right until the cartridge indenting engages the casing indenting.

Ensure that the two drilled holes in the influence block are an extension of the threaded holes

in the casing.

-

Attach the influence block to the casing with two bolts M12.

Herewith the unit is locked.

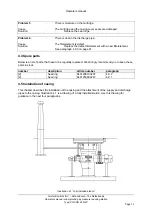

4.6.3 Leakage test

Check the station for gas leakages after installing the cartridge. You check the two upper and lower

seal rings for leaks with the leakage test (see paragraphs 4.9.1 and 4.9.2 on page 20).

Checking the lower seal rings as follows:

-

Open the casing cover.

-

Close the shut-off valve by pressing the emergency stop control button in.

-

Close the supply pipe's ball valve DN 50.

-

Close the butterfly valve DN150 in the discharge pipe, by turning the handle a quarter of a

turn to the left.

-

Open the valve in the supply pipe, located within 5 meter of the station.

-

Open the ball valve DN50 in the supply pipe, by turning the valve's handle slowly, a quarter of

a turn to the right.

The indicator on the pressure gauge, which shows the reduced pressure in the discharge pipe, may

not deflect. If the indicator deflects, then gas is leaking through the lower seal rings. Stop all

operations immediately (paragraph 4.7 on page 18) and replace the lower seal rings (paragraph 4.9.2

on page 21).

After checking if the lower seal rings are operating correctly, you can press the reset button on the

shut off relay.

-

Check for gas leakages between the casing and the cartridge with a leakage detector.

If there is a gas leakage, stop all operations immediately (paragraph 4.7 on page 18) and replace the

upper seal rings (paragraph 4.9.1 on page 21).

Replace the cartridge with a spare cartridge, if you cannot correct the malfunction on site.

The replaced cartridge must be checked by a maintenance engineer.