All Rights reserved, No Spreading without GOSUNCN Permission

53

Hardware Development Guide

ME3616

7.3.4.

M

ODULE

S

OLDERING

R

EFLOW

C

URVE

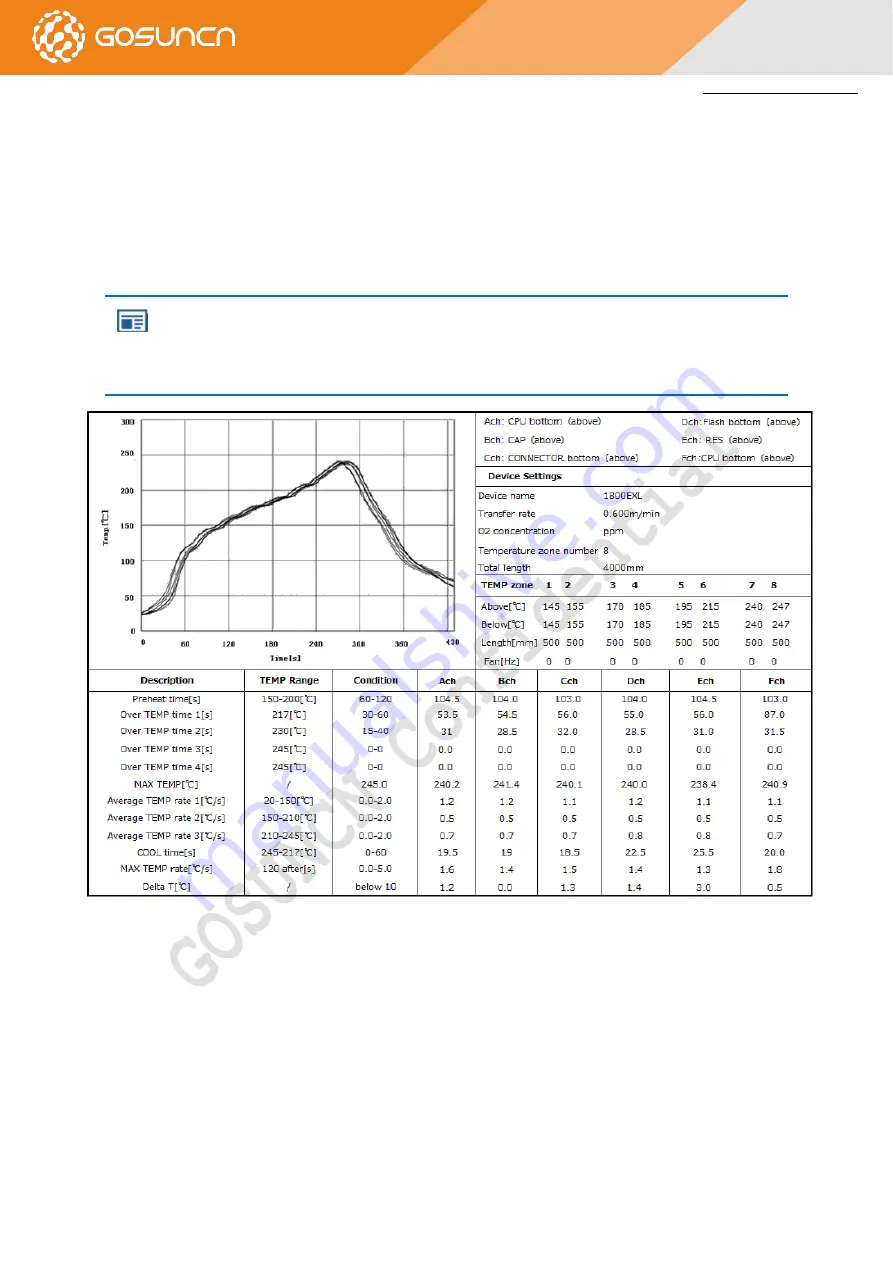

Module soldering furnace temperature curve is:

Peak value: 245+0/-5

℃

≥217

℃

: 30

~~

60S

150

~

200

℃

: 60

~~

120S

Temperature rise slope: <3

℃

/S

Temperature drop rate:

-

2

~-

4

℃

/S

NOTE:

The test board of furnace temperature must be the main board with the module board mounted on, and

there must be testing points at the position of module board.

Figure 7–4

Module Furnace Temperature Curve Reference Diagram

7.3.5.

R

EFLOW METHOD

If the main board used by customers is a double-sided board, it is recommended to mount the module board at the second

time. In addition, it is preferable for the main board to reflow on the mesh belt when mounting at the first time and the second time.

If such failure is caused by any special reason, the fixture should be also used to make such main board reflow on the track so as to

avoid the deformation of PCB during the reflow process.

7.3.6.

M

AINTENANCE OF DEFECTS

If poor welding occurs to the module board and main board, e.g., pseudo soldering of the module board and main board, the