7

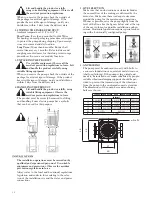

SAFETY INSTRUCTIONS

TO AVOID SERIOUS OR FATAL PERSONAL

INJURY OR MAJOR PROPERTY DAMAGE, READ

AND FOLLOW ALL SAFETY INSTRUCTIONS IN

MANUAL AND ON PUMP.

THIS MANUAL IS INTENDED TO ASSIST IN THE

INSTALLATION AND OPERATION OF THIS UNIT

AND MUST BE KEPT WITH THE PUMP.

This is a SAFETY ALERT SYMBOL.

When you see this symbol on the pump

or in the manual, look for one of the

following signal words and be alert

to the potential for personal injury or

property damage.

Warns of hazards that WILL cause

serious personal injury, death or major

property damage.

Warns of hazards that CAN cause

serious personal injury, death or major

property damage.

Warns of hazards that CAN cause per-

sonal injury or property damage.

NOTICE: INDICATES SPECIAL INSTRUCTIONS

WHICH ARE VERY IMPORTANT AND

MUST BE FOLLOWED.

THOROUGHLY REVIEW ALL INSTRUCTIONS

AND WARNINGS PRIOR TO PERFORMING ANY

WORK ON THIS PUMP.

MAINTAIN ALL SAFETY DECALS.

UNIT NOT DESIGNED FOR USE

WITH HAZARDOUS LIQUIDS OR

FLAMMABLE GASES. THESE

FLUIDS MAY BE PRESENT IN

CONTAINMENT AREAS.

The purpose of this manual is to provide the neces-

sary information for proper installation, operation and

maintenance of the e-SV pump. The instructions and

warnings provided below concern the standard version,

as described in the sale documents. Special versions may

be supplied with supplementary instructions leaflets.

Please refer to the sale contract for any modifications or

special version characteristics. Always specify the exact

pump type and identification code when requesting

technical information or spare parts from our Sales and

Service department. For instructions, situations or events

not considered in this manual or in the sale documents,

please contact your distributor.

Read this manual before installing and using

the product. Improper use may cause personal

injury and damage to property and lead to the

forfeiture of the warranty coverage.

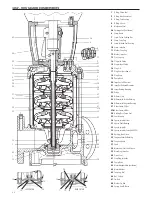

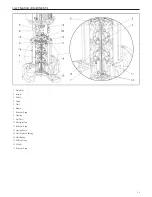

The e-SV pump is a vertical multistage, non-self priming

pump which can be coupled to standard electric motors.

For the pump sizes 1SV-22SV, some of the metal parts

that are in contact with the pumped liquid are made of

stainless steel, others are made of cast iron. They are

DANGER

WARNING

CAUTION

WARNING

Hazardous fluids can

cause fire, burns

or death.

available in different versions according to the position

of the suction and delivery ports and the shape of the

connection flanges. For the sizes 33SV-125SV, some of

the metal parts in contact with the pumped liquid are

made of stainless steel, others are made of cast iron. A

special version is available, in which all the metal parts

in contact with the pumped liquid are made of stainless

steel. If you purchase a pump without the electric motor,

make sure that the motor you use is suitable for coupling

to the pump. All e-SV pumps are equipped with a special

mechanical seal designed for easy replacement without

having to disassemble the entire pump.

These pumps are suitable for civil and industrial water

distribution systems, pressure booster, irrigation (agri-

culture, sporting facilities), water treatment, boiler feed,

parts washing, cooling - air conditioning - refrigeration

and fire fighting applications. The factory may be able

to configure certain models for pumping liquids having

atypical water and/or wastewater characteristics (e.g.,

acidic, basic, petrochemical or other non-aqueous liquids,

etc.). Any such specialty use requires consultation with

factory and engineering personnel for a detailed applica-

tion-specific evaluation.

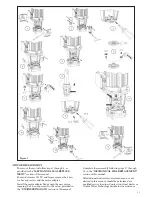

1. NAMEPLATE

Do not use this pump/electric pump unit to

handle flammable and/or explosive liquids.

Do not use this pump to handle liquids

containing abrasive, solid or fibrous

substances.

1 Goulds Water Technology Catalog Number

2

Capacity Range

3

TDH Range

4

Rated Speed

5

Rated Horsepower

6 Maximum Operating Pressure

7

Maximum Operating Temperature

8 Pump Serial Number

Confirm that the pump is capable of meeting the desired

operating conditions.

1. MINIMUM INLET (SUCTION) PRESSURE

In general, the minimum suction pressure required

is that which provides adequate NPSH

A

necessary to

feed the pump. The required NPSHr, expressed in

feet, can be found on the performance curve for the

pump at the specific duty point. It is recommended

WARNING