8

Check the direction of rotation (three-phase models only)

Clockwise rotation when looking at pump from the motor side.

Check by looking at the fan or by observing the pump’s

performance (in this case the correct direction of rotation is the one that generates the highest pressures and flows).

In the event of incorrect rotation, switch two supply wires.

6

Priming (fig. 7 and 8)

Fill the pump body and suction pipe through the fill plug, bleeding off all the air. For the GBG models, self-priming

without the foot valve may require up to 3-4 minutes. We therefore recommend that you always use a foot valve.

7

Maintenance

No scheduled routine maintenance is required. The pump should be serviced by qualified personnel only, after having

been disconnected from the power mains.

For models with switch and cable with plug assembled in the factory

If the power cable is damaged it must be replaced by the manufacturer or by their technical assistance service, or

anyway by a person with similar qualifications, so as to prevent any risk.

8

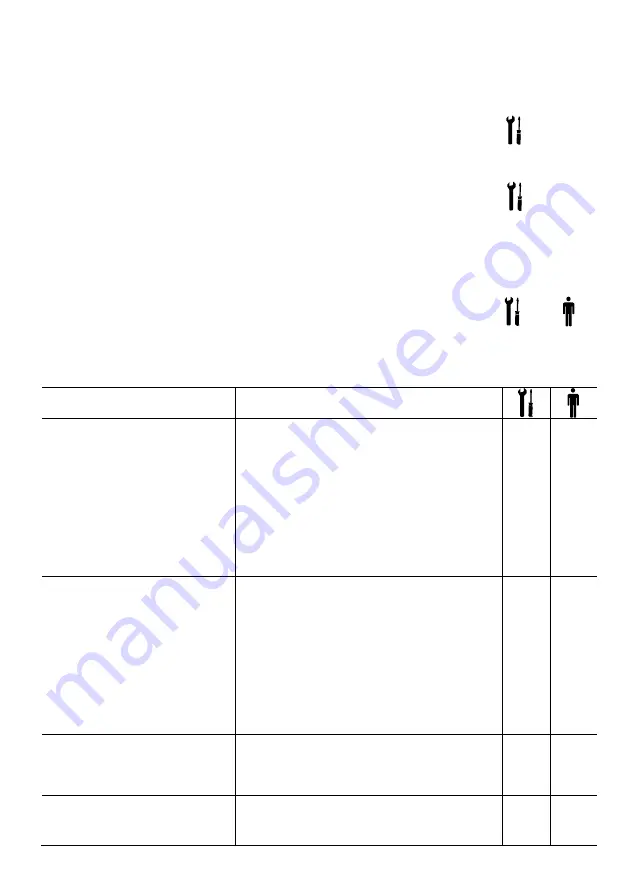

Troubleshooting

Always specify the exact pump/electric pump type and identification code (fig. 14) when requesting technical

information or spare parts from our Sales and Service department. Use only original spare parts to replace any worn

or faulty components. The use of unsuitable spare parts may cause malfunctions, damage and injuries. For any other

situation not contemplated in the table, refer to our Sales and Service Department.

Problem

Probable cause and possible solutions

The electric pump does not start.

● The thermo-amperometric protection incorporated

in the single-phase versions may have activated:

it will reset automatically once the motor has

cooled.

X

X

● Check the power supply and ensure connection

to the mains is intact.

X

● Reset the ground fault interrupter or circuit

breaker if it has triggered.

Replace any blown fuses.

X

● Triggering of protection device against dry

running. Check the water level in the tank, the

protection device and the respective connecting

cables.

X

The electric pump starts up but the

thermal protector is triggered after a

short time or the fuses blow.

● Power supply cable is damaged, electric motor

short circuit, thermal protector or fuses not suited

to the motor current Check the components and

replace as necessary.

X

● Triggering of thermoamperometric protection

(single-phase version) or of the protection device

(three-phase version) due to excessive current

input. Check the pump working conditions.

X

● A phase in the power supply is missing. Check

the power supply

X

● There are foreign bodies (solids or filaments)

inside the pump, the impellers are jammed.

Clean the pump.

X

The motor starts but the pump does

not deliver.

● The pump is sucking in air. Check the liquid level,

the tightness of the suction pipe and the

operation of the foot valve..

X

● Pump not correctly primed. Repeat the

procedure of filling the pump body.

X

The pump’s delivery is reduced.

● Check for throttling of the pipes.

X

● Wrong rotation direction (three-phase models).

Check the direction of rotation.

X

● Pump not correctly primed. Repeat the

X