Page 1331

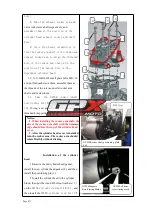

Cylinder block and piston repair

1. Maintenance Instructions

2. Disassembly of the cylinder

3. Cylinder inspection

4. Disassembly of the piston

5. Inspection of piston and piston ring

6. Installation of piston ring 7. Installation of piston

8. Installation of the cylinder

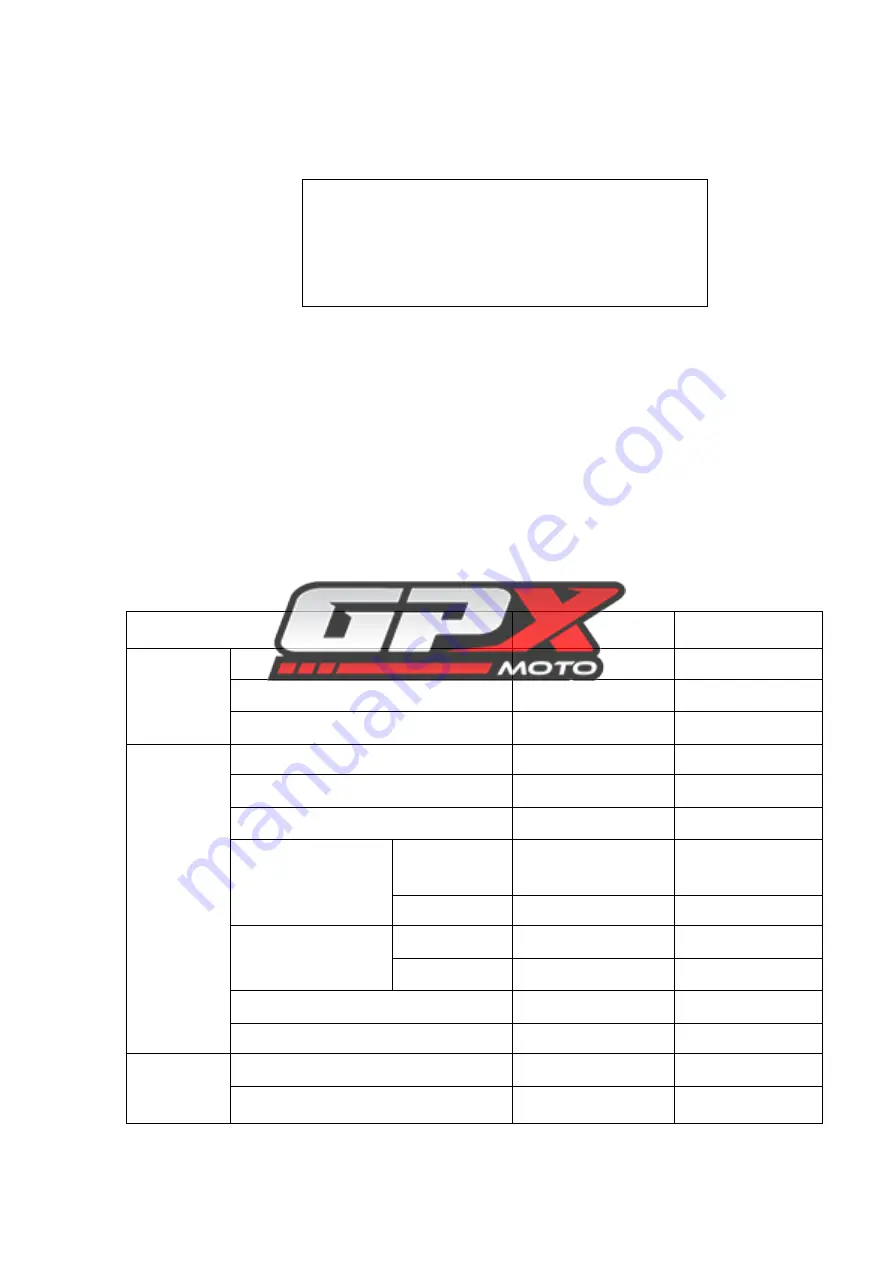

Maintenance notice

Notes

:

●

The cylinder head lubricating oil is supplied to the cylinder head through the small oil

hole next to the AB bolt on the left body of the engine. Before installing the cylinder,

make sure that the small oil hole next to the AB bolt on the left body is unobstructed.

Do not install the solid positioning pin of the cylinder block into the oil passage hole.

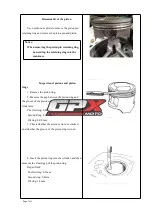

Maintenance parameters of each component

project

Standard value mm

Maintenance limit

mm

cylinder

Cylinder bore

φ

94.5

~φ

94.52

φ

94.528

Out of roundness

0.05

0.01

Cylinder surface flatness

0.03

0.05

piston

piston ring

live

plugged

Piston outside diameter

φ

94.45

~φ

94.46

φ

94.43

Piston pin hole inner diameter

φ

20.001

~φ

20.006

φ

20.015

Piston pin and piston pin hole clearance

0.001

~

0.012

0.025

Piston Ring Closed

Gap

Top

Ring/Second

Ring

0.2

~

0.35

0.5

oil ring

0.2

~

0.7

1.4

Piston ring and piston

ring groove clearance

top ring

0.03

~

0.07

0.08

second ring

0.02

~

0.06

0.08

Cylinder to Piston Clearance

0.035

~

0.065

0.07

Piston pin outer diameter

φ

19.994

~φ

20

φ

19.99

connecting

rod small end

the inside diameter of

φ

20.015

~φ

20.025

φ

20.04

Small end of connecting rod and piston

pin clearance

0.015

~

0.03

0.05