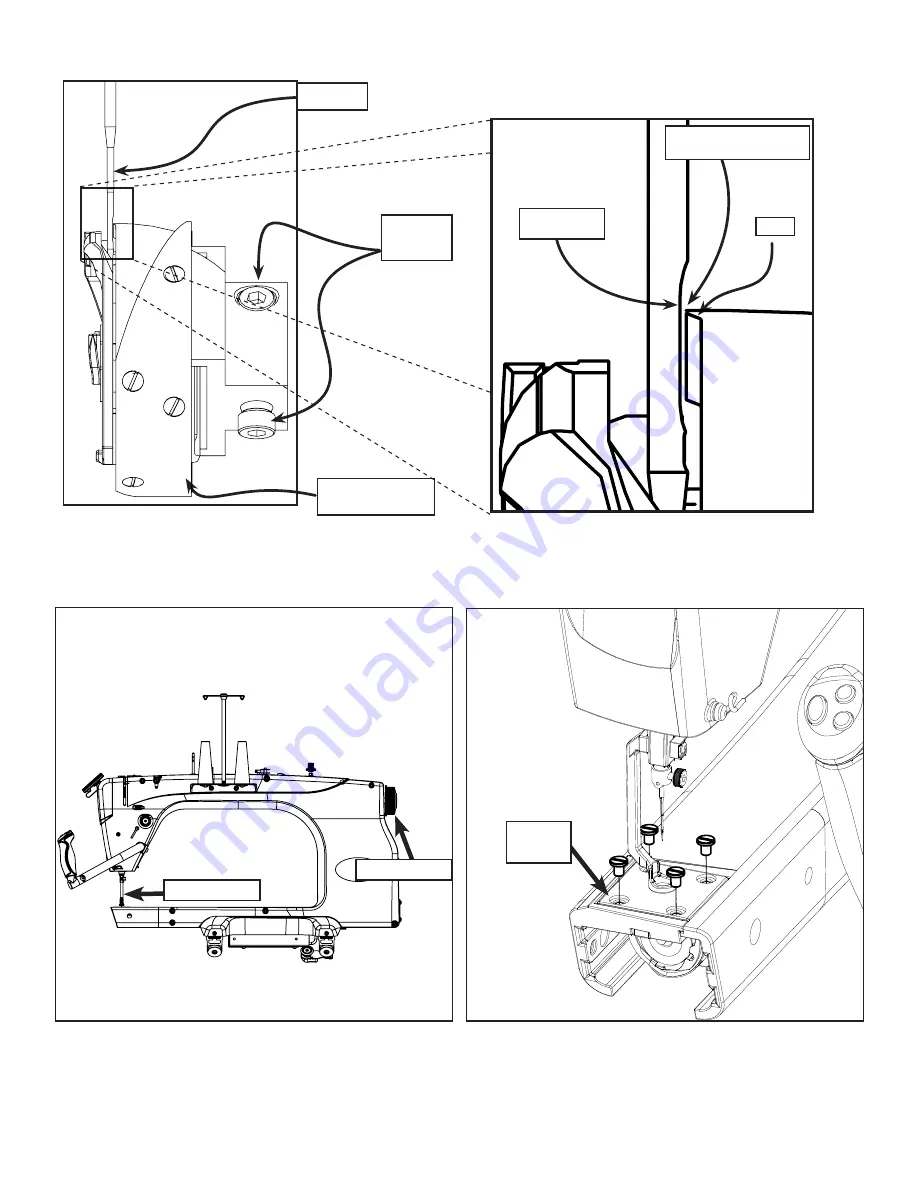

Needle Bar

Hand Wheel

6. Rotate the hand wheel a full rotation. If the

needle hits the Hook Assembly anywhere,

the needle will bend or there will be a clicking

noise. Adjust the needle height closer or

farther off from the hook.

5. The Needle should be as close as possible to the Hook Assembly without touching, roughly between

0.02mm and 0.075mm. Tighten the Set Screw which is currently aligned with the Timing Hole on

the left side of the machine.

Needle

Plate

7. Tighten the two remaining set screws and

reattach the Needle Plate.

Scarf

Hook Assembly

Needle

Set

Screws

Hook

8

0.02-0.75mm Gap

Summary of Contents for Q'nique 21

Page 1: ...Service Manual 21 ...