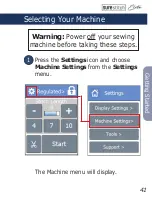

55

Get

ting Started

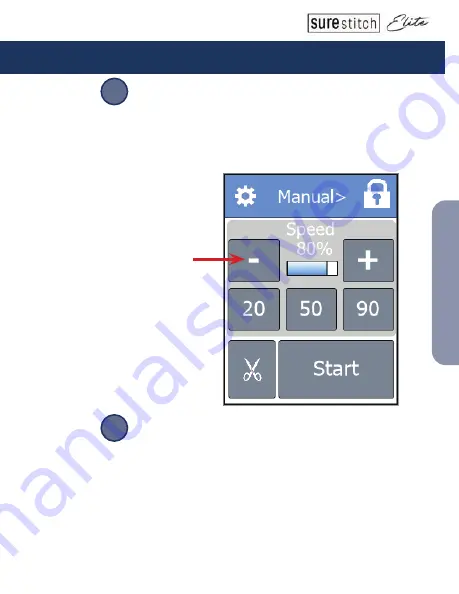

Press [-] to decrease the stitch

speed. It is easier to create large

basting stitches on a slow stitch

speed.

Stitch

Speed

Press [Start] to begin stitching!

Steadily move your machine across

the top of the quilt, where you want

the baste line to be. The faster you

move the machine, the longer the

stitches become.

a

b

Step 2 - Basting (Continued)

Summary of Contents for surestitch Elite

Page 1: ...surestitch Instructions ...

Page 6: ...6 Hardware Specs Handlebar Attachment Clip Full Color Touchscreen SureStitch Elite Screen ...

Page 7: ...7 Hardware Specs M5 Knob Control Box Connector Port Programming and Service Port SSE 09 20021 ...

Page 16: ...16 Screen Guide Screen Guide Sewing Modes 17 Menus 21 Tools Options and Features 27 ...

Page 78: ...The Grace Company Phone 1 800 264 0644 www graceframe com ...