43

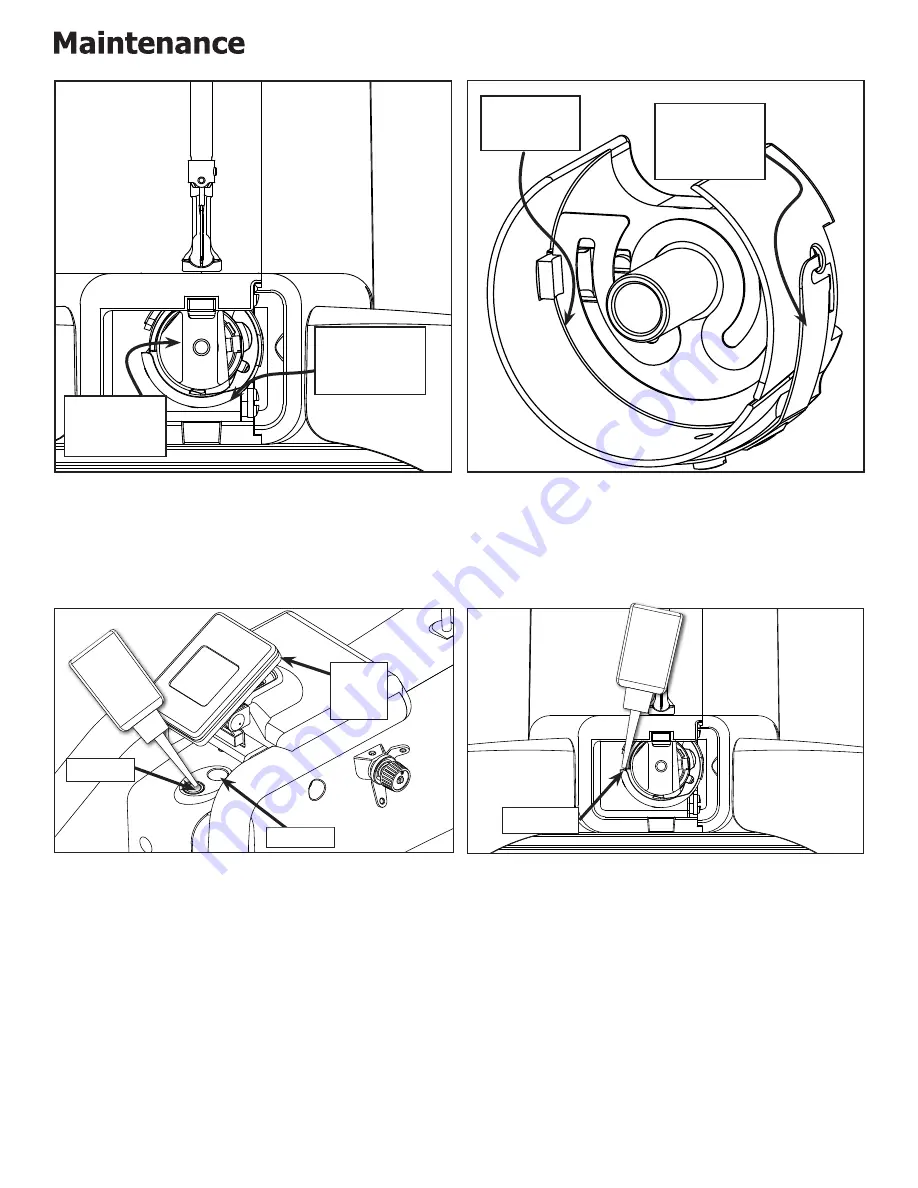

2. Remove the Bobbin.

3. Remove all lint and thread remnants.

4. Place the Bobbin back into the Bobbin Case.

Note: Once both components are clean

re-assemble the Bobbin Case and place it into the

Quilting Machine.

1. Remove all lint and any cloth and thread rem-

nants.

Note: You can use canned/compressed air to

clean this area out as well.

Frequency: Every 20hrs of use.

1. We recommend oiling at the beginning of each

project or oil before use if you have not used

your machine for more than 30 days.

2. Place 1-2 drops of oil in each hole on top of

the machine.

3.

After oiling, run the machine briefly to ensure

all components receive lubrication.

Note: The head of the machine and the Hook

Assembly are the only areas that require regular

lubrication.

Frequency: Once every other Bobbin change.

1. Remove the Bobbin Case.

2. Ensure all lint and thread remnants have been

removed.

3. Rotate the Hand Wheel so that the Needle is

halfway down, about a quarter turn. This will

put the hook in the optimal position to be oiled.

4. Place 1 to 2 drops of oil on the Hook Assembly

indicated by the arrow, pictured here.

5.

After oiling, run the machine briefly to ensure

all components receive lubrication.

1-2 Drops

1-2 Drops

Tilt the

Display

Back

1-2 Drops

Clean the

inside of the

Hook Assembly

Clean the area

around the

Hook Assembly

Clean the

inside of the

Bobbin Case

Clean the area

under the

Bobbin Thread

Tension Arm