16

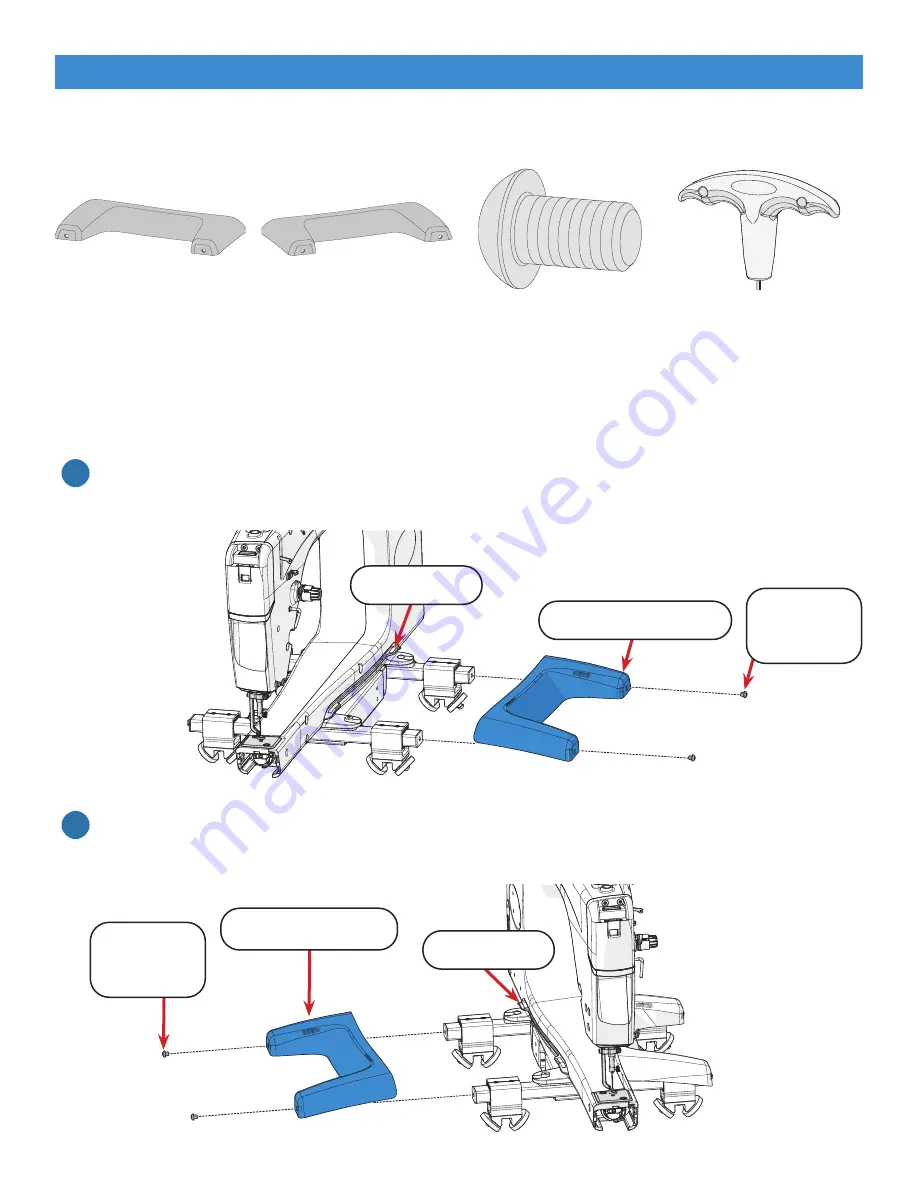

Parts & Tools Needed:

Instructions

Take the following steps to install the wheel covers onto the machine:

Installing the Wheel Covers

T-handle Allen

Wrench 4 mm

4 mm

SBHCS Screw

M6 x 16 mm (x4)

Plastic Base - Left

Plastic Base - Right

Out-of-the-Box Assembly

2.

Slide the

left plastic base

onto the left side of the machine. Screw two

M6 x 16 mm SBHCS

screws

into the plastic base using the 4 mm Allen wrench. Tighten until snug.

1.

Slide the

right plastic base onto the right side of the machine, over the side ridge

. Screw in

place with two

M6 x 16 mm SBHCS screws

and the 4 mm Allen wrench. Tighten until snug.

2

Plastic Base - Left

SBHCS Screw

M6 x 16 mm

(x2)

SBHCS Screw

M6 x 16 mm

(x2)

Plastic Base - Right

1

Side Ridge

Side Ridge