78

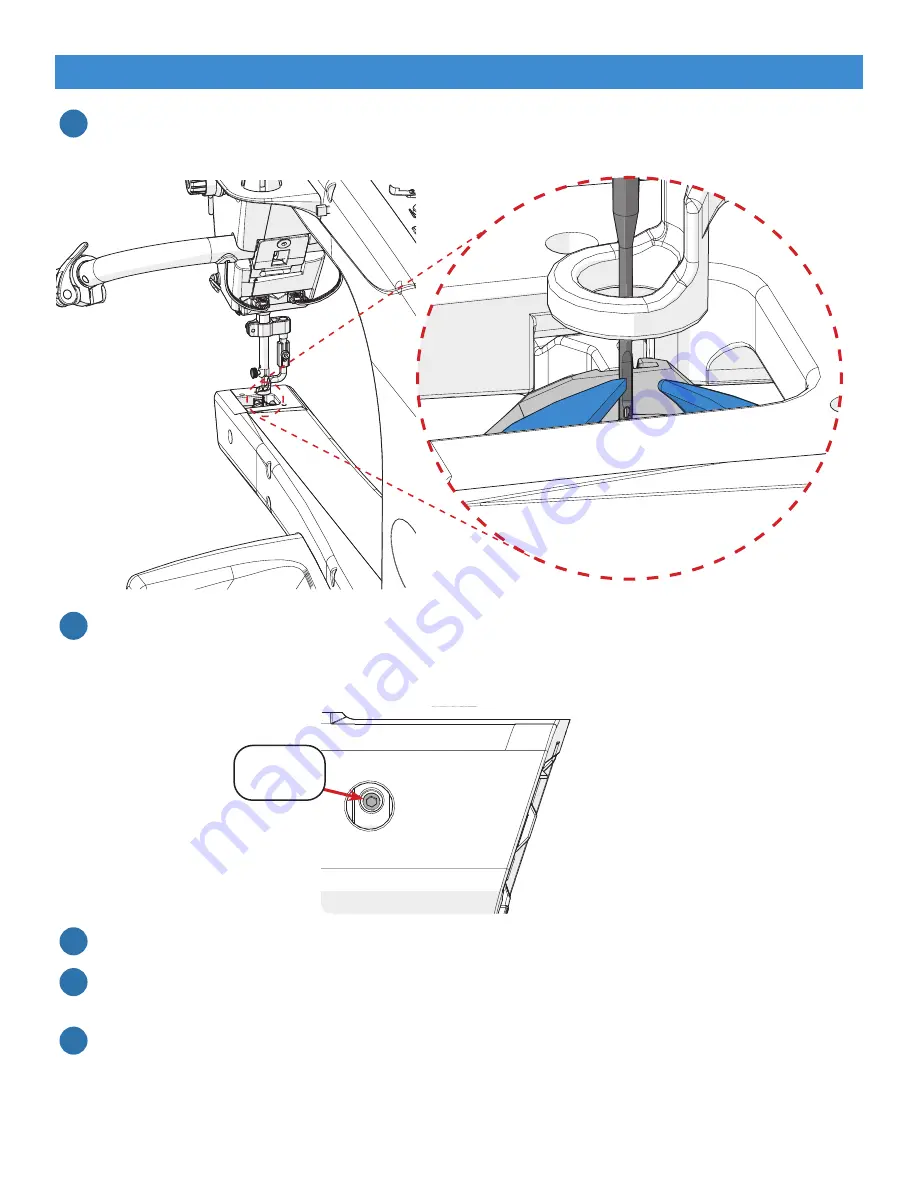

2. Push the hook assembly inward (toward the rear of the machine) while tightening the set screw

through the timing cut-out. Watch for bending in the needle and listen for a clicking sound that

could indicate the needle is hitting the hook.

13

1. Position the tip of the hook (shown in blue) in the middle of the back of the needle (shown in

gray). This is easier to see from the back of the machine.

12

Set Screw

3. Remove the timing spacer from the machine.

4. Turn the hand wheel a full rotation to ensure the needle does not hit the hook assembly at any

point.

5. Tighten the two remaining set screws through the timing cut-out. The needle plate and bobbin

case can be reinstalled.

14

15

16

Timing the Machine (Continued)

Repairs and Diagnostics