4. Place 4 sheets of paper under the foot and lower the hopping foot to the top of the surface. You

may need to use 2 sheets more or less of paper if your project is particularly thick or thin.

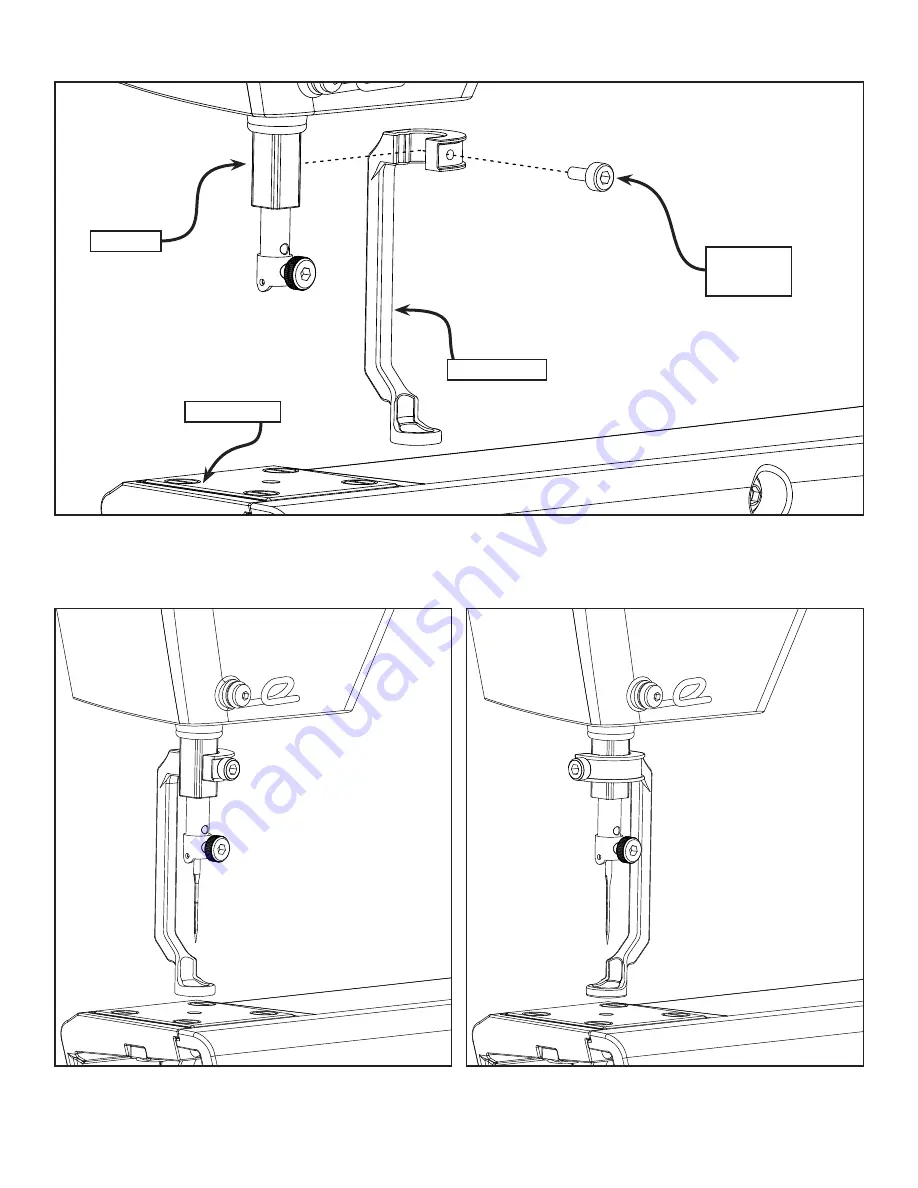

5. Tighten the bolt using the 3mm Allen Wrench.

Note:

The Hopping foot can be positioned in either of the positions shown.

Make sure not to overtighten the Hopping Foot to prevent binding the Press Bar.

35

|

Maintenance

Hopping Foot

Needle Plate

Hopping Foot

Press Bar

M3 Thumb

Screw