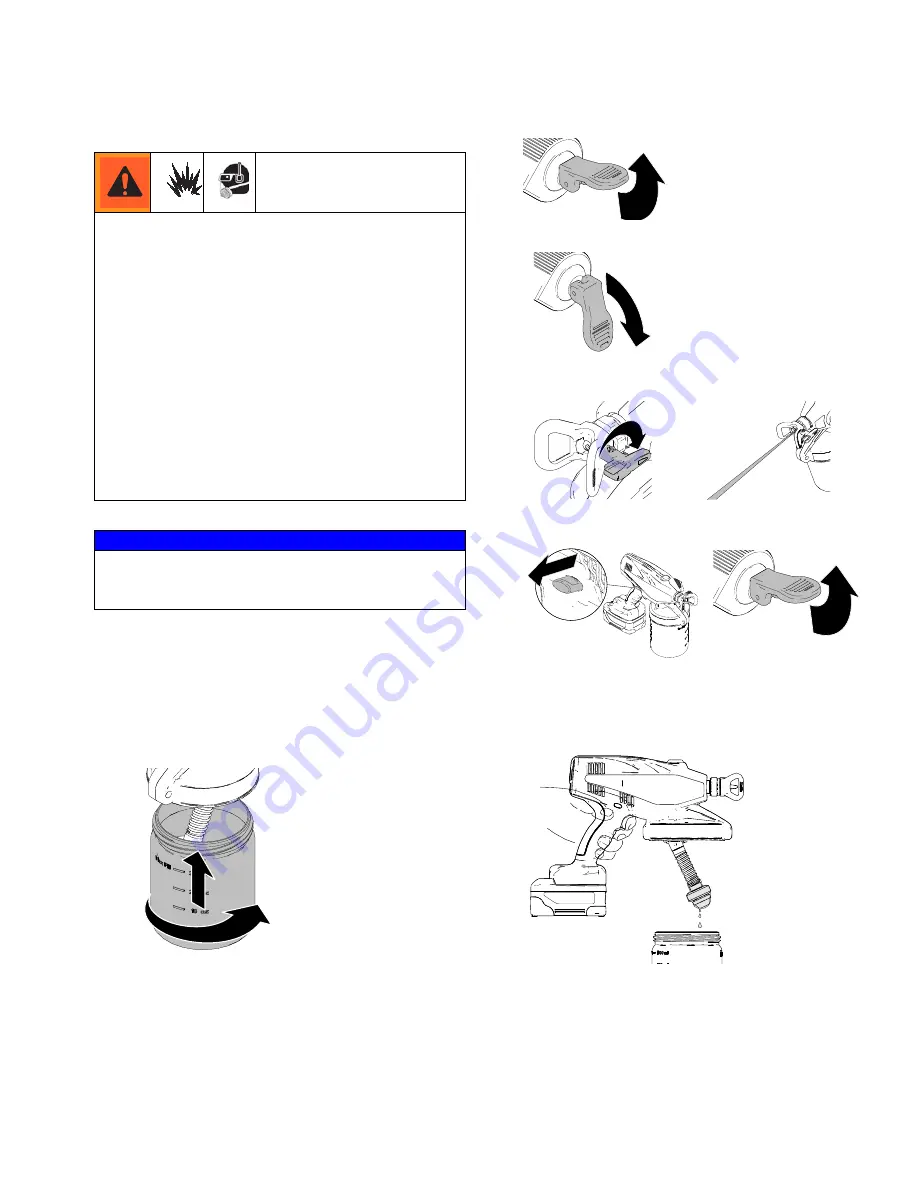

Sprayer Setup

10

3A2853C

Sprayer Setup

This sprayer arrives from the factory with a small

amount of test material in the system.

It is important

that you flush this material from the sprayer before

using it for the first time:

1.

Fill material cup with water or compatible solvent,

thread onto sprayer and hand tighten.

2.

Put prime/spray valve to UP position, then hold trig

ger in for 10 seconds.

3.

Put prime/spray valve DOWN to spray position.

4.

Reverse Spray Tip to UNCLOG position and trigger

sprayer into a waste area for 10 seconds.

5.

Engage trigger lock and put prime/spray valve UP to

release pressure.

6.

Unscrew and remove material cup.

7.

Disengage trigger lock, hold sprayer slightly above

material cup, and pull trigger to discharge fluid from

pump.

8.

Discard material in cup.

Use only water-based materials.

Do not use materi

als which state “FLAMMABLE” on the packaging. For

more information about your material, request SDS

from distributor or retailer.

Spraying certain materials may cause static

build-up in the sprayer that can result in static

shock to the user.

If this occurs, first ensure the mate

rial is water-based and does not state that it is FLAM

MABLE anywhere on the package. If still feeling a

static shock, the material likely contains a flammable

solvent such as, but not limited to, xylene, toluene, or

naphtha, which can build up static. Switch to an alter

native material.

Keep spray area well-ventilated.

Keep a good supply

of fresh air moving through the area.

NOTICE

Your sprayer is

NOT

compatible with harsh cleaners

such as chlorine bleach. Using these cleaners will

cause damage to the sprayer.

ti18871a

ti14999a

ti16700a

ti15425a

ti16701a

ti15491

ti16713a

ti14991a

ti14999a

ti14994a

ti18866a

ti16700a

ti18861a

Summary of Contents for 16N664

Page 33: ...Notes 3A2853C 33 Notes...