Spin Test

311990F

15

Spin Test

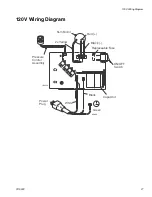

See Wiring Diagram, page 27.

To check armature, motor winding and brush electrical

continuity:

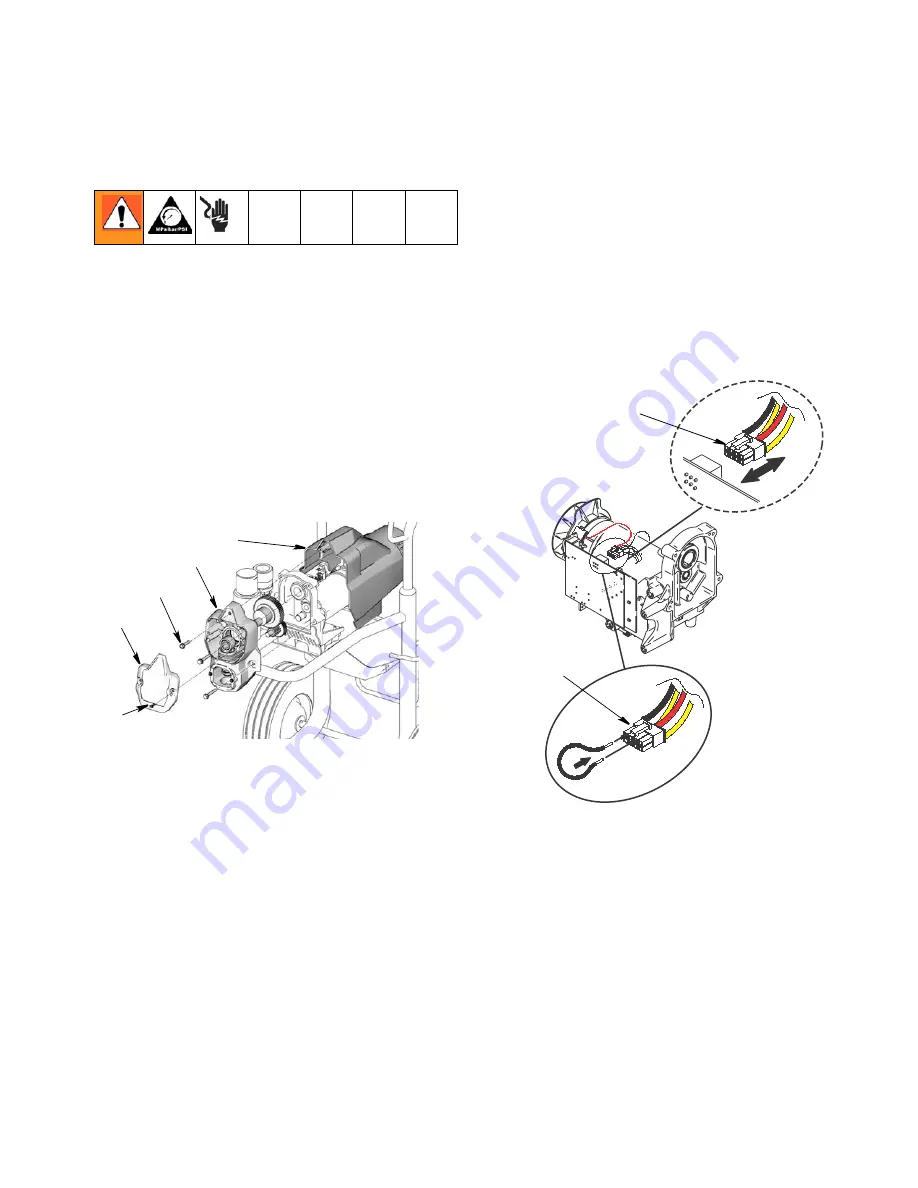

1.

Relieve pressure

, page 6. Disconnect power cord

from outlet.

2.

Remove kick stand (66) on (210

ES

Series A).

3.

Remove two screws (5) and toolbox (3) (190

ES

,

210

ES

Series A).

4.

Remove two screws (11) and front cover (32).

5.

Remove screw (13) and shroud (12).

6.

Remove drive housing (29), page 14.

7.

Disconnect motor connector (D).

Armature Short Circuit Test

Quickly turn motor fan by hand. If motor coasts two or

three revolutions before complete stop, there are no

electrical shorts. If motor does not spin freely, armature

is shorted. Replace motor, page 26.

Armature, Brushes, and Motor Wiring Open

Circuit Test (Continuity)

1.

Connect red and black motor leads with test lead.

Turn motor fan by hand at about two revolutions per

second.

2.

If uneven or no resistance, check for missing brush

caps, broken brush springs, brush leads, and worn

brushes. Repair as needed, page 17.

3.

If still uneven or no resistance, replace motor, page 26.

4.

Connect motor connector (D).

5.

Install drive housing, page 14.

6.

Install shroud (12) with screw (13).

7.

Install front cover (32) with two screws (11).

8.

Install toolbox (3) with two screws (5) (190

ES

, 210

ES

Series A).

9.

Install kick stand (66) on (210

ES

Series A).

11

32

13

29

12

ti9150a

D

ti9135a

D