8

GC-1412D

3.

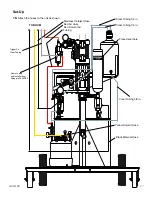

Attach air manifold p/n 23555-00 to the air motor.

4.

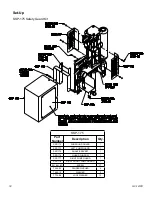

0RXQWFDWDO\VWERWWOHEUDFNHWZLWKVXSSOLHGXEROWV

p/n CP-126, 34in. from the top of the cart, to the top

RIWKHFDWDO\VWEUDFNHWDQGSDUDOOHOZLWKWKHPDWHULDO

pump.

5.

,QVWDOOWKHFDWDO\VWMXJZLWKWKHHOERZ¿WWLQJIDFLQJWKH

front of the unit.

6.

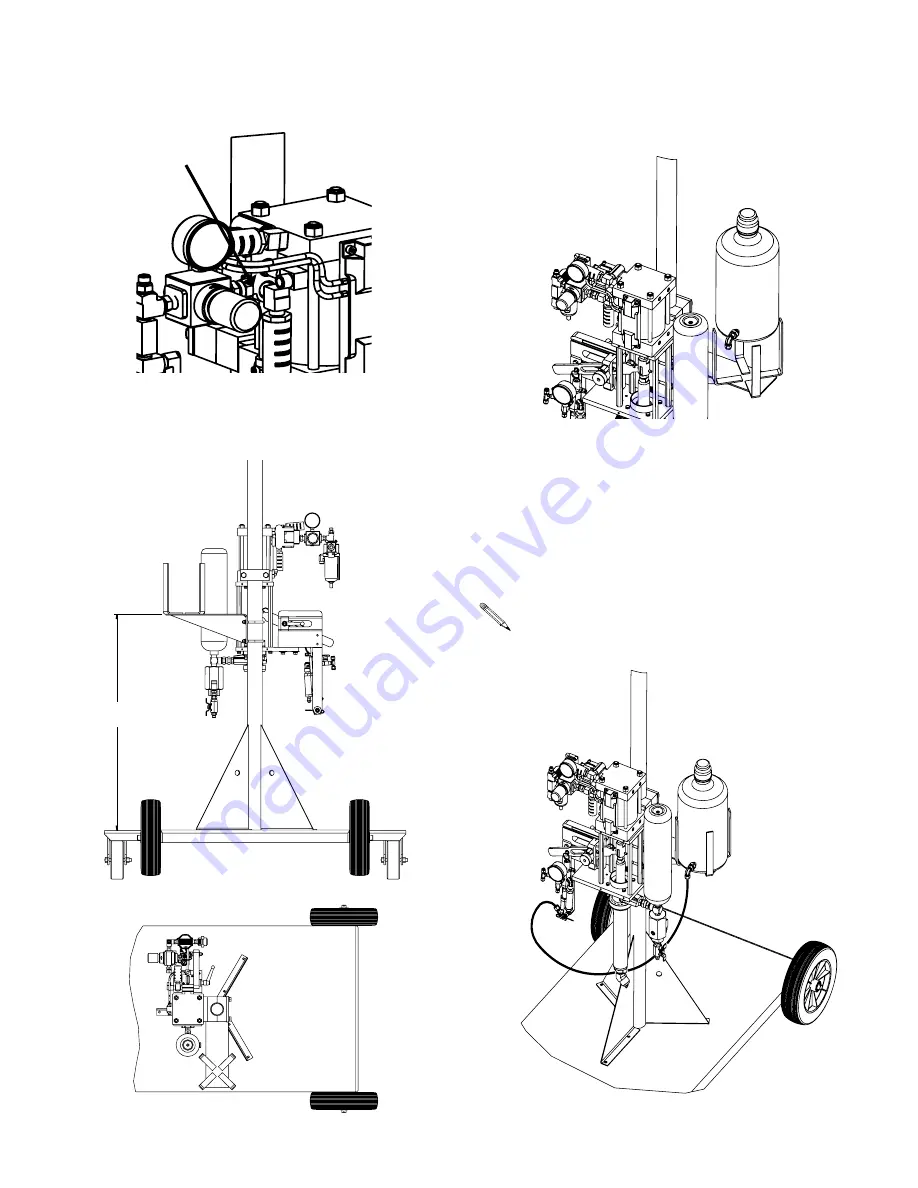

Install tubing p/n 9704-11 from the catalyst jug to the

LQOHW¿WWLQJRQWKHFDWDO\VWSXPS3XVKWKHWXELQJLQWR

WKHFDWDO\VWMXJVXSSO\¿WWLQJXQWLOLWVWRSV8VLQJWZR

proper sized

wrenches,

carefully

tighten the compres-

VLRQQXWWRORFNGRZQWKHWXELQJ

The tubing must be cut to desired length, giving a

natural gravity feed supply to the slave pump.

34in./86cm.

APPROX.

Set-Up

Summary of Contents for 20864-05

Page 31: ...GC 1412D 31 Notes ...