308584 13

Installation

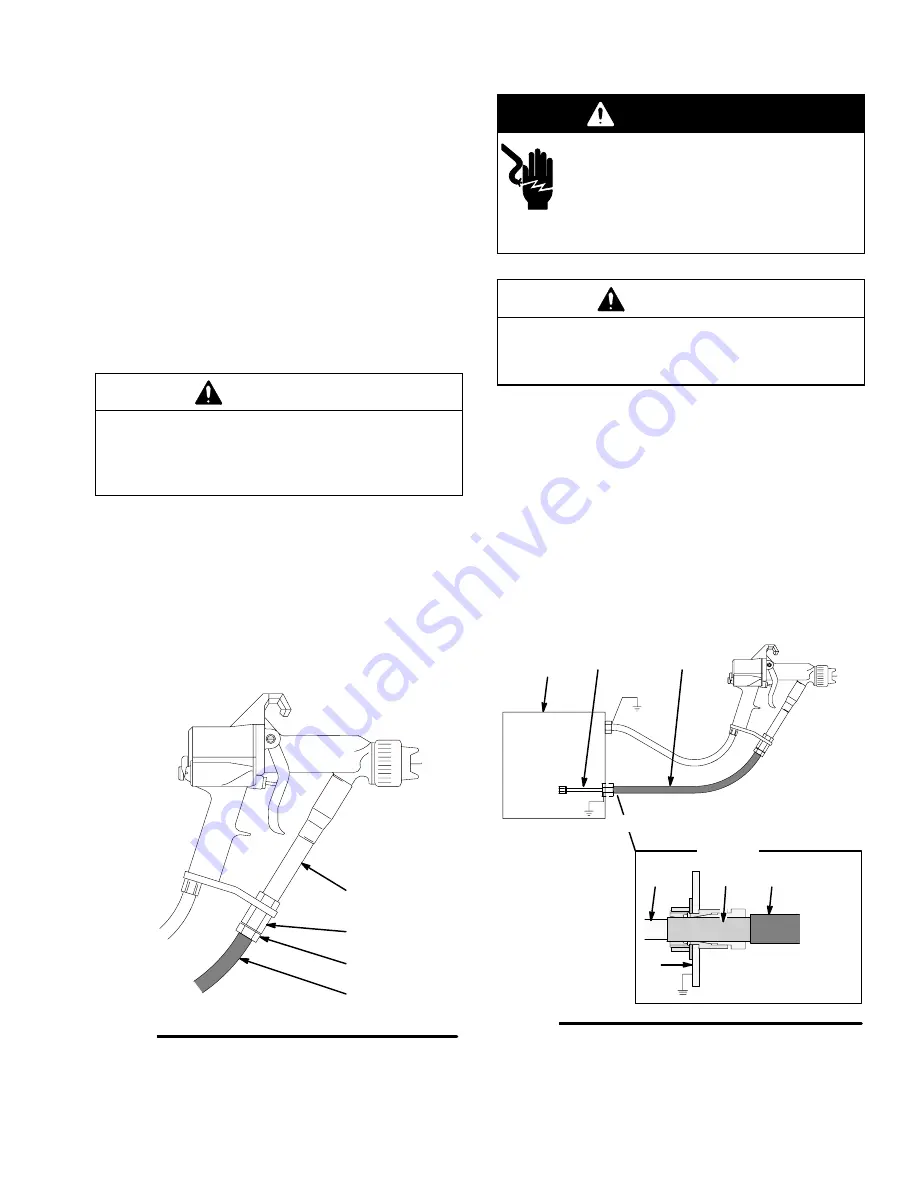

Connect the Fluid Hose (continued)

5.

Insert the hose (Y) into the hose ferrule housing

(79). See Fig. 5.

6.

Push the hose firmly through the fluid inlet tube

(75) until the o-rings on the hose barbed fitting are

seated and the hose bottoms out.

7.

Tighten the hose ferrule (77) firmly with a wrench

to about 50 in-lb (5.6 N

m). Pull back on the hose

to make sure it is secure. If not, disconnect the

hose and inspect it for damage. Check the hose

connection periodically for signs that the hose is

loosening.

CAUTION

If the hose comes loose from the fitting, fluid leakage

will occur. Make sure the hose ferrule (77) is tight

and that nothing will pull or catch on the hose during

operation.

8.

Connect the other end of the hose to the isolated

fluid supply as instructed in the voltage isolation

system manual. See Fig. 6.

KEY- Fig. 5

Y

Graco Waterborne Fluid Hose

75 Fluid Inlet Tube

77 Hose Ferrule

79 Hose Ferrule Housing

Fig. 5

75

77

79

Y

Torque to 50 in-lb (5.6 N

m)

05405B

WARNING

ELECTRIC SHOCK HAZARD

To reduce the risk of an electric shock,

the areas of the waterborne fluid hose

that are accessible to personnel during

normal operation must be covered by the outer

hose jacket (H). See Fig. 6.

CAUTION

The Graco warranty is void if the spray gun is con-

nected to a non-Graco voltage isolation system or if

the gun is operated above 60 kV.

KEY- Fig. 6

H

Outer Hose Jacket

K

Inner Hose Layer

R

Voltage Isolation System Enclosure

Fig. 6

K

H

H

K

DETAIL

R

H

2

O PRO Voltage Block

connection shown

J

R

The areas of the waterborne fluid hose that are accessible to

personnel during normal operation must be covered by the outer

hose jacket (H).

The portion of the inner hose layer (K) that is not covered by

the outer hose jacket (H) must be inside the voltage isolation

system enclosure (R).

The conductive hose layer (J) must be grounded through its

connection to the isolation system’s grounded safety fence or

enclosure (R).

05149B

Summary of Contents for 222700

Page 50: ...50 308584 N ...