34 308584

Service

Fluid Packing Rod Removal and Repair

(continued)

7.

Place the packing nut (28c) and o-ring (28f) on the

fluid rod (28a). Flats on the packing nut must be

facing toward the back of the fluid rod.

8.

Fill the entire inner cavity of the spacer (28h) with

the dielectric grease included with the gun. Place

the spacer on the fluid rod (28a), in the direction

shown in Fig. 20. Generously apply the grease to

the outside of the spacer.

9.

Place the fluid packing (28e), needle packing

(28d), and housing (28b) on the fluid rod (28a), as

shown in Fig. 20.

10. Lightly tighten the packing nut (28c) with the multi-

tool (62). The packing nut is properly tightened

when there is 2 lbs. (9 N) of drag force when slid-

ing the packing housing (28b) assembly along the

shaft. Tighten or loosen the packing nut as need-

ed.

11. Lubricate the o-ring (28g).

12. Make sure the spring (30) is installed against the

nut (U) as shown in Fig. 20.

13. Install the fluid packing rod assembly (28) into the

gun barrel. Using the multi-tool (62), tighten the

assembly until just snug.

14. Install the trigger (13) and tighten the trigger

screws (4). See Fig. 19.

15. Install the electrode needle, fluid nozzle and resis-

tor stud assembly and the air cap assembly as

instructed on page 32.

16. Test the gun resistance as instructed on page 28.

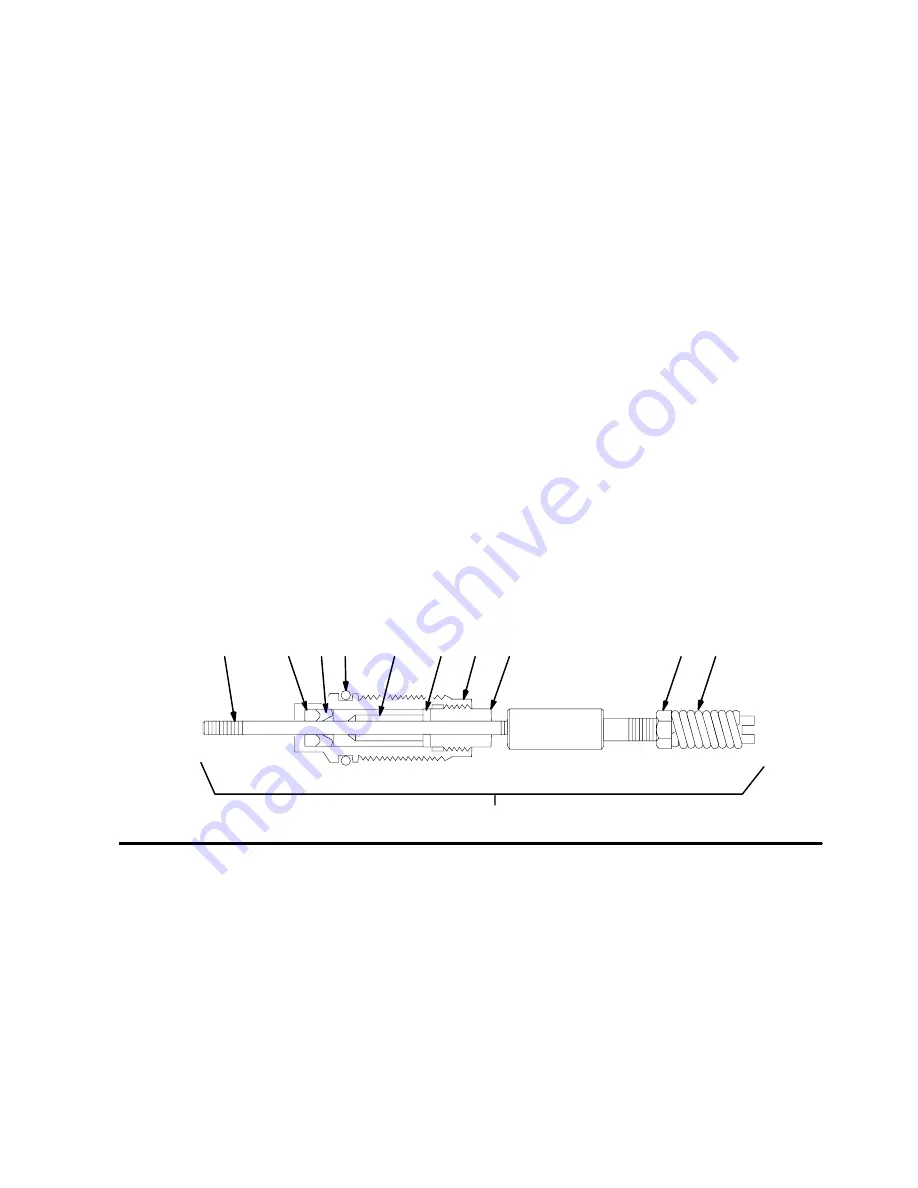

Fig. 20

28g

30

28

28b 28c

28d

28

f

28a

28h

U

03558

28e

Apply a very light coat of lubricant to the o-ring (28g).

Fill the inner spacer (28h) cavity with the dielectric grease and generously lubricate the outside of the spacer.

Tighten the packing nut (28c) to 2 lbs (9 N) of drag force.

The spring (30) is not included with the fluid packing rod assembly (28)

Summary of Contents for 222700

Page 50: ...50 308584 N ...