12

307–920

OPERATION

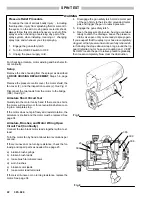

Pressure Relief Procedure

To reduce the risk of serious bodily injury, including

fluid injection, splashing fluid or solvent in the eyes

or on the skin, or injury from moving parts or electric

shock, always follow this procedure whenever you

shut off the sprayer , when checking or servicing

any part of the spray system, when installing,

cleaning or changing spray tips, and whenever you

stop spraying.

1. Engage the gun safety latch.

2. Turn the ON/OFF switch to OFF.

3. Disengage the gun safety latch. Hold a metal

part of the gun firmly to the side of a grounded

metal pail, and trigger the gun to relieve

pressure.

4. Engage the gun safety latch.

5. Open the pressure drain valve, having a con-

tainer ready to catch the drainage. Leave the

valve open until you are ready to spray again.

If you suspect that the spray tip or hose is com-

pletely clogged, or that pressure has not been fully

relieved after following the steps above, wrap a rag

around the tip guard retaining nut or hose end cou-

pling and VERY SLOWLY loosen the part to relieve

pressure gradually, then loosen completely . Now

clear the tip or hose.

WARNING

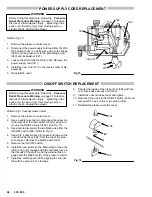

Startup

Use this procedure each time you start the sprayer to

help ensure the sprayer is ready to operate and that you

start it safely.

NOTE:

For the first time startup, be sure to flush the

sprayer first. See page 15.

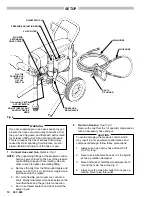

1. Close the pressure drain valve.

If you have not in-

stalled a secondary hose, be sure the adapter is se-

curely plugged with the plug provided.

See Fig 4.

2. Don’t install a spray tip in the gun yet!

3

.

Put the suction tube into the material container

.

4. Lower the pressure setting

by turning the pressure

adjusting knob all the way counterclockwise.

See Fig

4.

5. Disengage the gun safety latch.

See Fig 7.

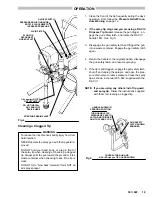

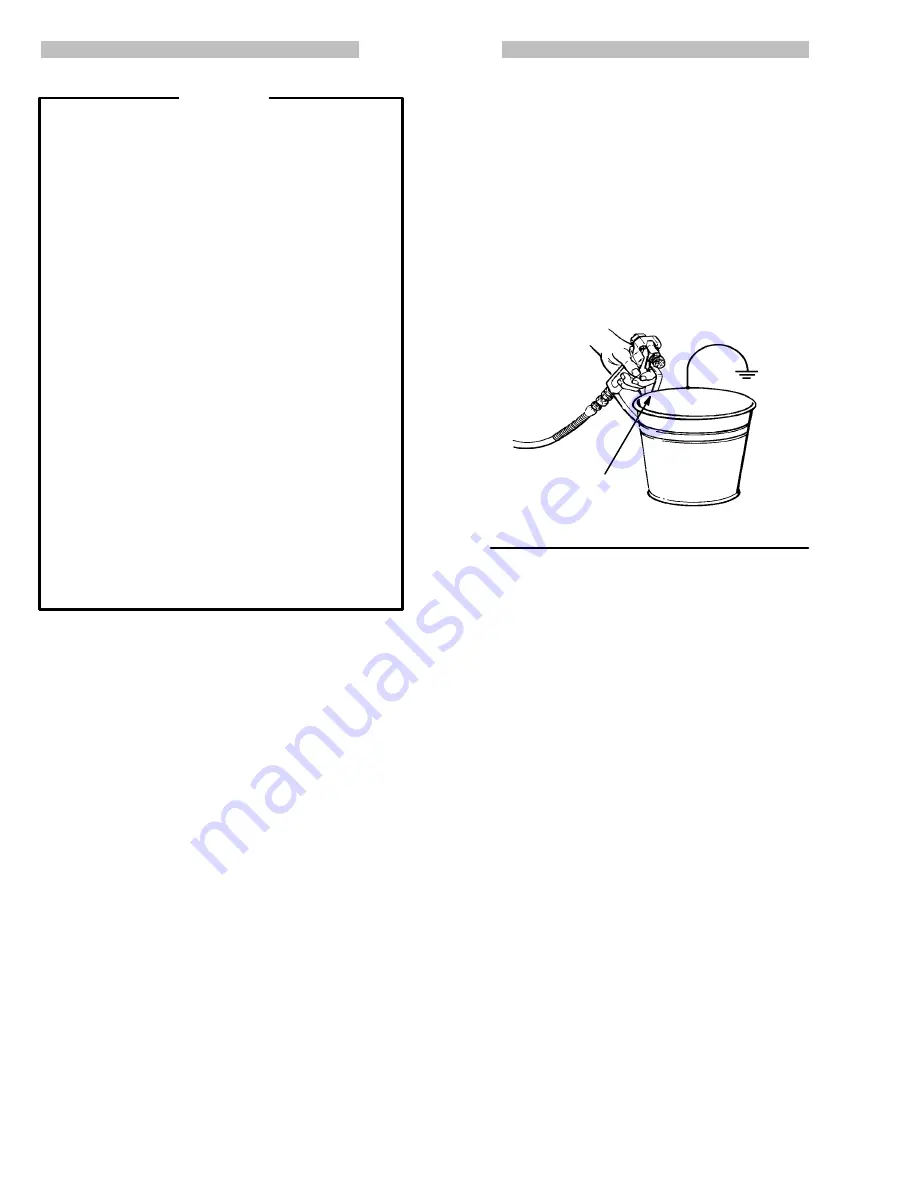

6. To prime the pump

, hold a metal part of the gun

firmly against and aimed into a metal waste con-

tainer.

See Fig 6. Squeeze the trigger and hold it

open, turn the ON/OFF switch to ON, and slowly in-

crease the pressure setting until the sprayer starts.

Keep the gun triggered until all air is forced out of the

system and the material flows freely from the gun.

Release the trigger and engage the gun safety latch.

NOTE:

If the pump is hard to prime, place a container

under the pressure drain valve and open it.

When fluid comes from the valve, close it. Then

disengage the gun safety latch follow Step 6.

Fig 3

MAINTAIN FIRM

METAL TO METAL

CONTACT WHEN

FLUSHING

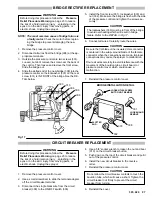

7. Check all fluid connections for leaks

. If any are

found, follow the

Pressure Relief Procedure Warn-

ing

, to the left, before tightening connections.

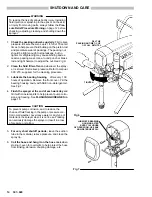

8. Install the Spray Tip and Tip Guard.

Be sure the

gun safety latch is engaged.

See Fig 7. Install the

spray tip. If using the RAC IV DripLess tip guard, re-

fer to manual 307–848, supplied with the gun, for in-

stallation instructions.

9. Adjust the Spray Pattern

a. Check your material manufacturer’s spray pres-

sure recommendations. While the gun is spray-

ing, increase or decrease the pressure adjusting

knob setting until the pressure gauge reads the

correct pressure range.

b. To avoid excessive overspray and fogging, and

to decrease tip wear and extend the life of the

sprayer, always use the lowest possible pres-

sure needed to get the desired results.

c. If more coverage is needed, use a larger tip

rather than increasing the pressure.

d. Test the spray pattern. To adjust the direction of

the spray pattern, engage the gun safety latch

and loosen the retaining nut. Position the tip

guard horizontally for a horizontal pattern or ver-

tically for a vertical pattern. Then tighten the re-

taining nut.

Summary of Contents for 231-081

Page 47: ...47 307 920...