15

307–920

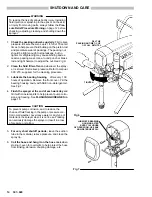

FLUSHING GUIDELINES

When to Flush

1.

New Sprayer.

Your new sprayer was factory tested

in lightweight oil which was left in to protect pump

parts.

Before using water–base material, flush with mineral

spirits followed by soapy water , and then a clean

water flush.

Before using oil–base material, flush with mineral

spirits.

2.

Changing Colors.

Flush with a compatible solvent.

3.

Changing from water–base to oil–base material.

Flush with warm, soapy water, then mineral spirits.

4.

Changing from oil–base to water–base material.

Flush with mineral spirits, followed by warm, soapy

water, then a clean water flush.

5.

Storage.

Water–base material: flush with water, then mineral

spirits. Relieve pressure.

Oil–base material: flush with mineral spirits. Relieve

pressure.

NEVER leave water in the sprayer if there is the

slightest chance it could freeze. Push the water out

with mineral spirits. Water left to freeze in the pres-

sure control tube prevents the sprayer from being

started and causes serious damage to the pressure

control.

CAUTION

6.

Startup after storage.

Before using water–base material, flush out the min-

eral spirits with soapy water and then a clean water

flush. When using oil–base material, flush out the

mineral spirits with the material to be sprayed.

How to Flush

1. Follow the

Pressure Relief Procedure Warning

on

page 12.

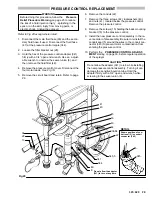

2. If the sprayer has been used before, remove the filter

bowl and screen; see manual 307–273, supplied.

Clean the screen separately and install the bowl with-

out the screen to flush it.

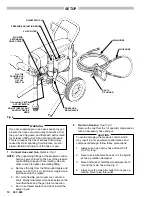

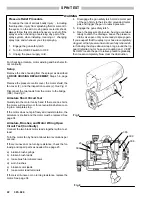

See Fig 8.

Fig 8

PRESSURE

DRAIN VALVE

FILTER

BOWL

SCREEN

FILTER

SUPPORT

3. Close the pressure drain valve.

4. Put the suction tube in a grounded metal pail of com-

patible solvent.

5. Remove the spray tip from the gun, if it is installed.

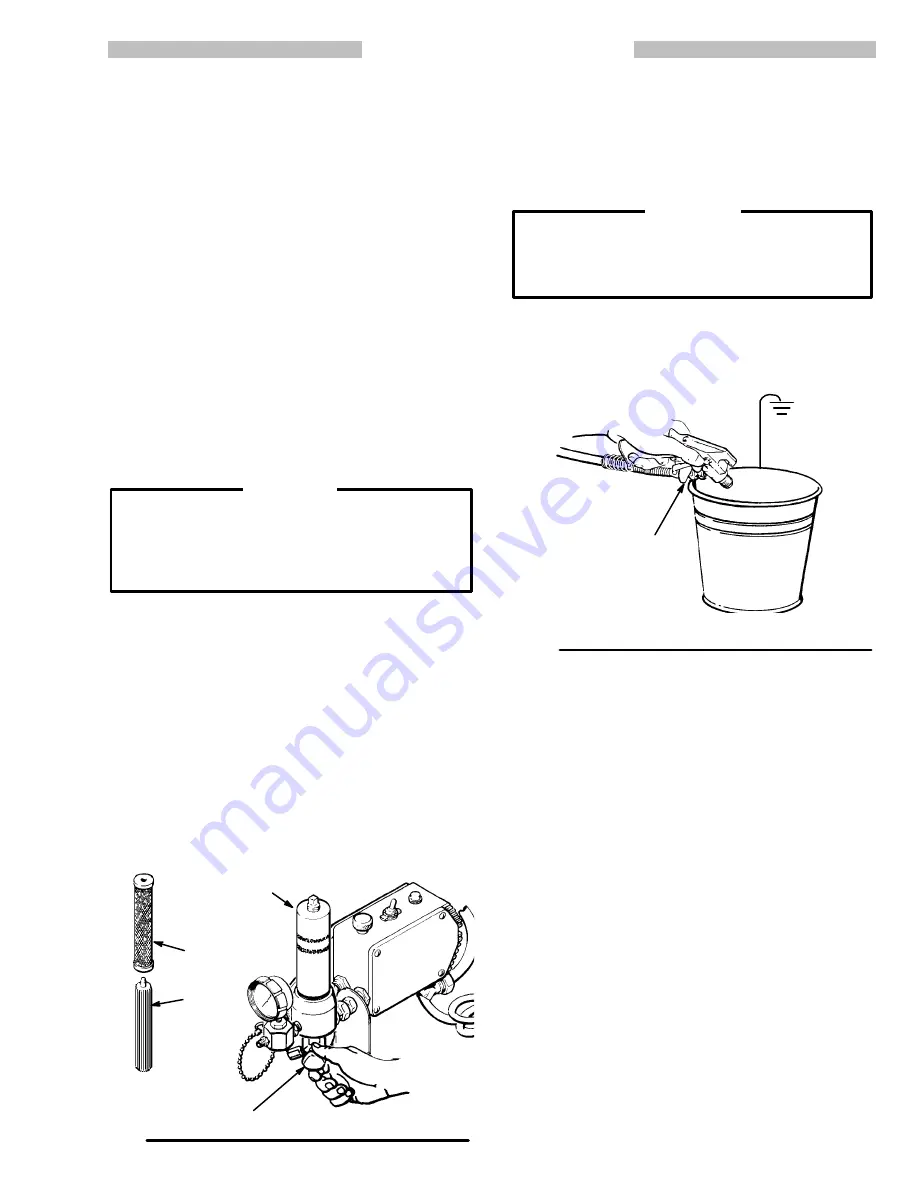

WARNING

To reduce the risk of static sparking and splashing,

always remove the spray tip from the gun, and hold

a metal part of the gun firmly to the side of and aimed

into a grounded metal pail when flushing.

6. Lower the pressure setting by turning the pressure

adjusting knob all the way counterclockwise.

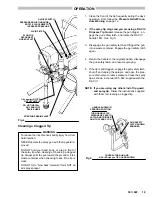

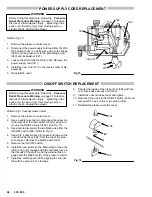

Fig 9

MAINTAIN FIRM

METAL TO METAL

CONTACT WHEN

FLUSHING

7. Hold a metal part of the gun firmly against and aimed

into a metal waste container.

See Fig 9. Squeeze the

trigger and hold it open, turn the ON/OFF switch to

ON, and slowly increase the pressure setting until

the sprayer starts. Keep the gun triggered until all air

is forced out of the system and the solvent flows

freely from the gun. Release the trigger and engage

the gun safety latch. This procedure helps reduce the

risk of static sparking and splashing.

NOTE:

If the pump is hard to prime, place a container

under the pressure drain valve and open it.

When fluid comes from the valve, close it.

8. Remove the suction tube from the pail. Disengage

the gun safety latch and trigger the gun to force sol-

vent from the hose. Do not let the pump run dry for

more than 30 seconds to avoid damaging the pump

packings! Relieve pressure.

9. Leave the pressure drain valve open until you are

ready to use the sprayer again. If the screen was re-

moved, unscrew the filter bowl and reinstall the clean

screen. Reinstall the bowl, hand tight only.

10. If you flushed with mineral spirits and are going to use

a water–base material, flush with soapy water fol-

lowed by a clean water flush. Relieve pressure.

Summary of Contents for 231-081

Page 47: ...47 307 920...