16

307–920

TROUBLESHOOTING GUIDE

WARNING

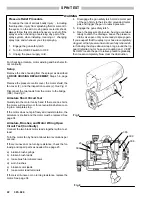

Pressure Relief Procedure

To reduce the risk of serious bodily injury , including

fluid injection, injury from splashing fluid or solvent in

the eyes or on the skin, moving parts or electric shock,

always follow this procedure whenever you shut off the

sprayer, when checking or servicing any part of the

spray system, when installing, cleaning or changing

spray tips, and whenever you stop spraying.

1. Engage the gun safety latch.

2. Turn the ON/OFF switch to OFF.

3. Unplug the power supply cord.

4. Disengage the gun safety latch. Hold a metal part

of the gun firmly to the side of a grounded metal

pail, and trigger the gun to relieve pressure.

5. Engage the gun safety latch.

6. Open the pressure drain valve, having a container

ready to catch the drainage. Leave the pressure

drain valve open until you are ready to spray again.

If you suspect that the spray tip or hose is completely

clogged, or that pressure has not been fully relieved af-

ter following the steps above, wrap a rag around the tip

guard retaining nut or hose end coupling and VER Y

SLOWLY loosen the part to relieve pressure gradually,

then loosen completely. Now clear the obstruction.

Check everything in the guide before disassembling the sprayer.

Basic Mechanical Problems

Basic Fluid Pressure Problems

Basic Electrical Problems

!

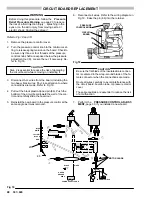

Thaw the sprayer if water or water–based material has frozen in it, due to exposure to low temperatures, by placing it in a warm

area. Do not try to start the sprayer until it has thawed completely. If the bourdon tube was not damaged by the freezing, the pump

should operate. If material hardened (dried) in the sprayer, the pump packings and/or pressure control must be replaced. See page

36 or page 29.

1. Slowly increase the pressure setting to see

if the motor starts.

2. Relieve pressure, refer to your separate gun

or tip instruction manual for tip cleaning.

1. Thaw

!

. Plug in sprayer and turn on. Slowly in-

crease pressure setting to see if motor

starts. If it doesn’t, replace the displacement

pump packings (see page 36) and/or re-

place the pressure control (301)

@

. See page

29.

2. Push pin into place and secure with the

spring retainer.

3. Replace motor (1) if fan won’t turn.

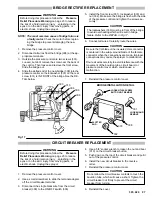

1. Depress button to reset. If circuit breaker

continues to open, see ‘Electrical Short’ on

page 22.

2. Reset building circuit breaker; replace build-

ing fuse. Try another electrical outlet.

3. Replace extension cord.

4. Replace power supply cord. See page 26.

5. Tighten terminal screws; replace brushes.

See page 25.

1. Check the pressure control knob setting.

The motor will not run if it is at the mini-

mum setting (fully counterclockwise).

2. Check for a clogged spray tip. See your

separate gun or tip instruction manual.

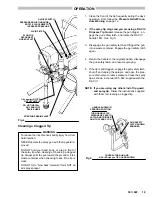

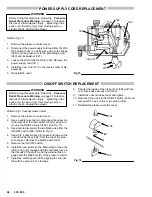

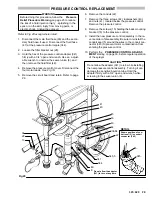

1. Check for frozen or hardened material in

the pump (39) and/or pressure control

bourdon tube. Using a screwdriver, care-

fully try to rotate fan at back of motor by

hand. See page 22.

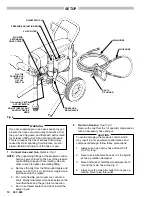

2. Check displacement pump connecting

rod pin (20). It must be completely pushed

into connecting rod (3) and retaining

spring (35) must be firmly in groove of

connecting rod. See page 32.

3. Check for motor damage. Remove drive

housing assembly (2). See page 33. T ry

to rotate fan by hand.

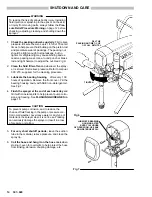

1. Check sprayer circuit breaker (309) but-

ton to be sure it has not popped up.

2. Check electrical supply with volt meter .

Meter should read 105–125 VAC.

3. Check extension cord for visible damage.

Use a volt meter or test lamp at extension

cord outlet to check.

4. Check sprayer power supply cord (311)

for visible damage such as broken insula-

tion or wires.

5. Check motor brush leads, terminals and

brush length. Brush length should be 1/2”

minimum. See page 25.

WHAT TO CHECK

If check is OK, go to the next check.

TYPE OF PROBLEM

WHAT TO DO

If check is not OK, refer to this column.

MOTOR WON’T OPERATE

Summary of Contents for 231-081

Page 47: ...47 307 920...