307–920

SPIN TEST

Pressure Relief Procedure

To reduce the risk of serious bodily injury , including

fluid injection, injury from splashing fluid or solvent in

the eyes or on the skin, moving parts or electric shock,

always follow this procedure whenever you shut off the

sprayer, when checking or servicing any part of the

spray system, when installing, cleaning or changing

spray tips, and whenever you stop spraying.

1. Engage the gun safety latch.

2. Turn the ON/OFF switch to OFF.

3. Unplug the power supply cord.

4. Disengage the gun safety latch. Hold a metal part

of the gun firmly to the side of a grounded metal

pail, and trigger the gun to relieve pressure.

5. Engage the gun safety latch.

6. Open the pressure drain valve, having a container

ready to catch the drainage. Leave the pressure

drain valve open until you are ready to spray again.

If you suspect that the spray tip or hose is completely

clogged, or that pressure has not been fully relieved af-

ter following the steps above, wrap a rag around the tip

guard retaining nut or hose end coupling and

VERY

SLOWLY loosen the part to relieve pressure gradually,

then loosen completely. Now clear the obstruction.

WARNING

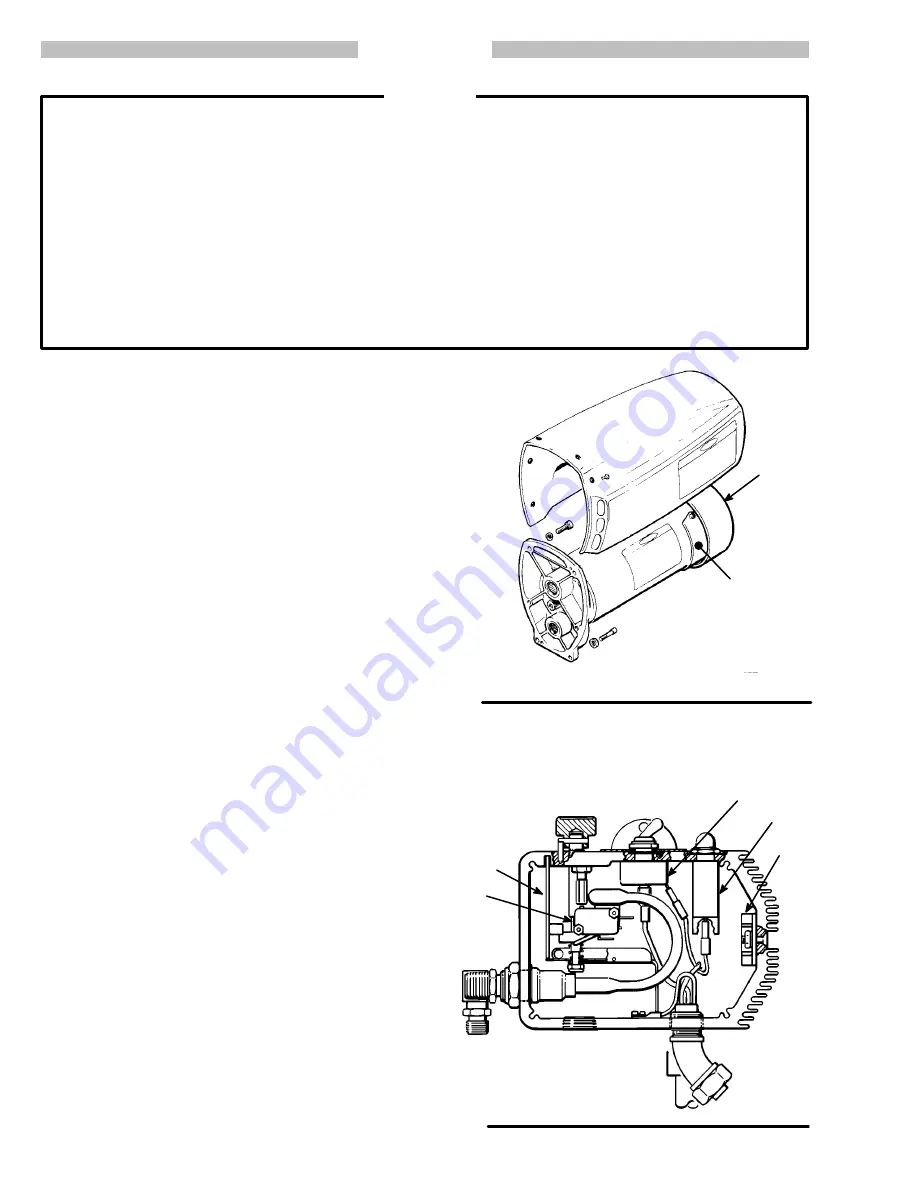

For checking armature, motor winding and brush electri-

cal continuity.

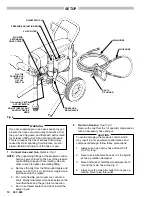

Setup

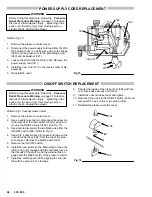

Remove the drive housing from the sprayer as described

in

DRIVE HOUSING REPLACEMENT

, Steps 1–6, page

33.

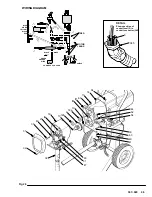

Remove the pressure control cover, the motor shield, the

fan cover (F), and the inspection covers (J).

See Fig 8.

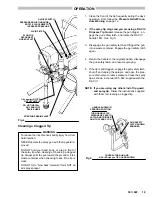

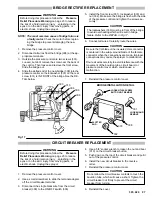

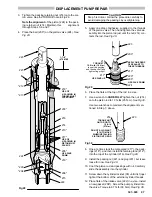

Disconnect the two leads from the motor to the bridge

(308).

See Fig 9.

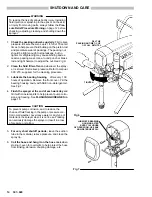

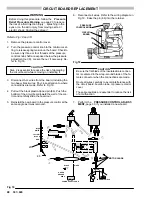

Armature Short Circuit Test

Quickly turn the motor fan by hand. If there are no shorts,

the motor will coast two or three revolutions before com-

ing to a complete stop.

If the motor does not spin freely and resists rotation, the

armature is shorted and the motor must be replaced. See

page 34.

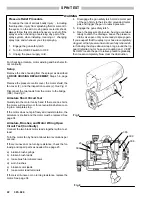

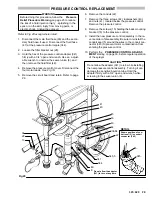

Armature, Brushes, and Motor Wiring Open

Circuit Test (Continuity)

Connect the two black motor leads together with a test

lead.

Turn the motor fan by hand at about two revolutions per

second.

If there is uneven or no turning resistance, check the fol-

lowing and repair parts as needed. See page 23.

a) broken brush springs

b) broken brush leads

c) loose brush terminal screws

d) worn brushes

e) broken motor leads

f) loose motor lead terminals

If there is still uneven or no turning resistance, replace the

motor. See page 34.

F

J

Fig 8

Fig 9

308

303

309

23

302

Summary of Contents for 231-081

Page 47: ...47 307 920...