30

307–920

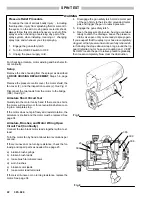

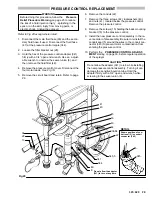

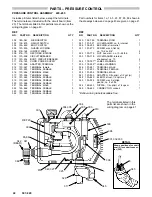

PRESSURE CONTROL ADJUSTMENT

This procedure sets the sprayer to3000 psi (210 bar)

MAXIMUM WORKING PRESSURE and sets the

overpressurization switch (microswitch) to approxi-

mately 3600 psi (242 bar).

Perform this procedure whenever the pressure con-

trol assembly is removed and reinstalled or replaced,

or a new circuit board is installed.

Improper adjustment can cause the sprayer to over-

pressurize and result in component rupture, fire or ex-

plosion. It may also prevent the sprayer from obtaining

the maximum working pressure, resulting in poor

sprayer performance.

NEVER try to increase the sprayer’s maximum work-

ing pressure of 3000 psi (210 bar ) by performing

these adjustments in any other way. Normal operation

of the sprayer at higher pressures may result in com-

ponent rupture, fire or explosion. To perform this ad-

justment, however, the sprayer pressure must be

tem-

porarily increased above the normal working pres-

sure.

Use a

new 50 ft (15.2 m) spray hose rated for at least

3000 psi (210 bar) MAXIMUM WORKING PRES-

SURE. A used, under–rated hose could develop a

high pressure leak or rupture.

WARNING

USE EXTREME CAUTION WHEN PERFORMING THIS ADJUSTMENT PROCEDURE

to reduce the risk of a

fluid injection injury or other serious bodily injury which can result from component rupture, electric shock, fire,

explosion, or moving parts.

NOTE:

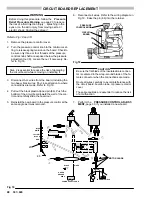

The following tools and equipment are required

for this procedure.

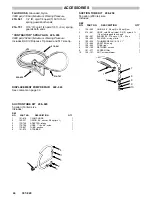

3/8 in. nut driver or 3/8 in. socket wrench

1/4 in. open end wrench

7/16 in. open end wrench

0 – 5000 psi, oil–filled test gauge, Part No. 102–814

Pail of clean water

Mineral spirits

NEW 3000 psi (210 bar) high pressure spray hose,

Part No. 214–915

CAUTION

DO NOT use the gauge supplied with this sprayer

to perform this adjustment. It is a 3000 psi (210 bar)

gauge, and will be damaged if the system pressure

is raised to 3800 psi (266 bar) as required by this

adjustment. Use gauge 102–814 or the equivalent.

1. Follow the

Pressure Relief Procedure Warning

on

page 23.

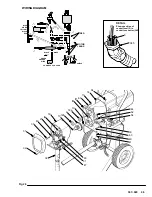

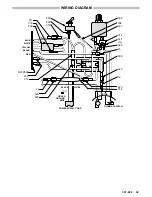

2. Refer to the above list of tools and equipment need-

ed. Remove the standard gauge and install the 5000

psi (350 bar) gauge. Connect the gun to the

new

test

hose and connect the hose to the sprayer outlet.

3. Remove the pressure control cover.

4. Place the pump suction tube in a pail of clean water.

5. Be sure the gun safety latch is engaged.

NOTE:

For Steps 5 through 18, refer to Fig 31–1.

6. Plug in the sprayer.

7. Turn the pressure control knob (B) to the

minimum

setting (fully counterclockwise), and turn the sprayer

ON.

THE DISPLACEMENT PUMP SHOULD NOT

CYCLE

If it does cycle,

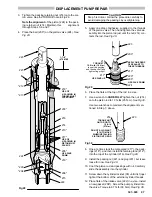

remove the plug (87) from the bot-

tom of the pressure control. Insert a 3/8 in. nut driver

through the opening, and unscrew the pressure ad-

justment nut (T) just until the sprayer stops running.

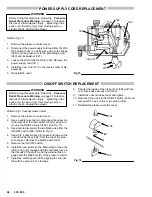

Adjust the Overpressurization Switch

8. With the spray gun triggered,

slowly

turn the pres-

sure control knob clockwise just until the sprayer

starts. Prime the pump and hose. Release the trig-

ger.

9. Slowly turn the pressure control knob to the maxi-

mum setting. While watching the red light on the cir-

cuit board and the pressure gauge, turn the nut (T)

slowly

to increase pressure until the red light goes

out

and

the gauge reads between 3400 –3800 psi

(238 – 266 bar).

If the red light does not go out by 3800 psi (266

bar),

loosen the nut (P) and adjust the stud (Q) until

the light goes out.

If the red light goes out before 3400 psi (238 bar),

loosen the nut (P) and adjust the stud (Q) until the

light goes out between 3400 – 3800 psi (238 – 266

bar).

10. Tighten the nut (P) if it was loosened in Step 9.

11. Trigger the gun to relieve pressure. Release the trig-

ger and engage the safety latch. Repeat Step 9 to

verify your results.

12. Install the pressure control cover.

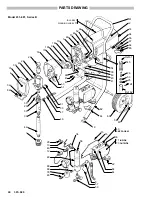

Summary of Contents for 231-081

Page 47: ...47 307 920...