308620

30

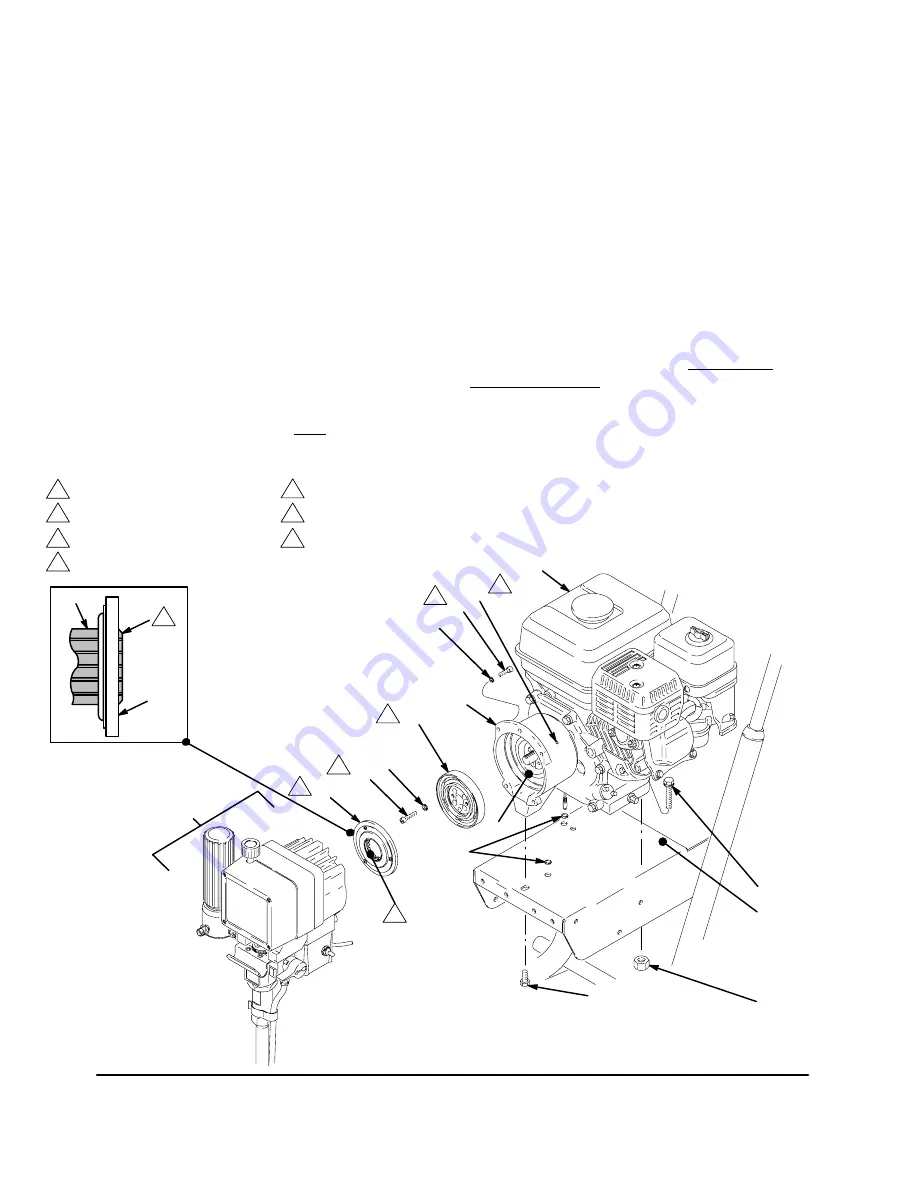

Reassembly

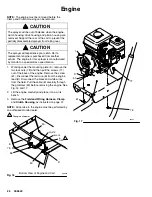

6.

Be sure the face of the

rotor (51a)

and the clamp

(55) are free of all burrs. Install the rotor, lock-

washers (16) and capscrews (57). Torque the

capscrews to 7 ft–lb (9.5 N.m). See Fig. 23.

7.

After installing the rotor (51a) the air gap must be

adjusted between the rotor and the field (53).

Tighten the setscrews (58) oppositely and evenly.

Pull the engine recoil rope to assure that the

engine turns freely, and there is no contact be-

tween the rotor and the field. If there is contact,

loosen the setscrews and reposition the field.

NOTE:

With the autogap style armature, the gap be-

tween the rotor and the armature is critical for proper

operation. The clutch kits with an autogap style arma-

ture include a cardboard spacer (p/n 186857) to set

the proper gap. This spacer is for use

only

during

installation.

8.

Clean the face of the

armature (51b)

. With the flat

side of the armature facing the rotor (51a), slide

the armature onto the hub (2h) in the drive/pinion

assembly (D) just until the chamfered end of the

hub (2h) protrudes through the armature. See

Detail B, Fig. 23. There will be significant resis-

tance. Attach the cardboard spacer, supplied with

the clutch kit, to the face of the armature. Bend

tabs over outside diameter of armature.

Brace the cart against a wall to keep it from rolling.

Push the drive/pinion assembly onto the clutch

housing (1). There will be significant resistance.

When the mating surfaces of the drive/pinion as-

sembly and the clutch housing (1) are flush, re-

move the drive/pinion assembly.

Remove the

cardboard spacer.

9.

Assemble the

drive assembly (D)

to the clutch

housing (1), using the capscrews (59) and lock-

washers (16). See Fig. 23.

05843C

05843B

Fig. 23

A

78

61

51b

16

51a

53

1

48

57

58

77

16

59

1

3

4

2

Torque the screw to 7 ft–lb (9.5 N.m).

The face must be clean.

1

2

Spline

4

2

To engine alternator.

Detail B

5

52

2h

D

50

Chamfered end of hub (2h)

5

06007

6

Apply low strength thread locker.

7

Torque to 100 in.-lb (N

m).

7

6