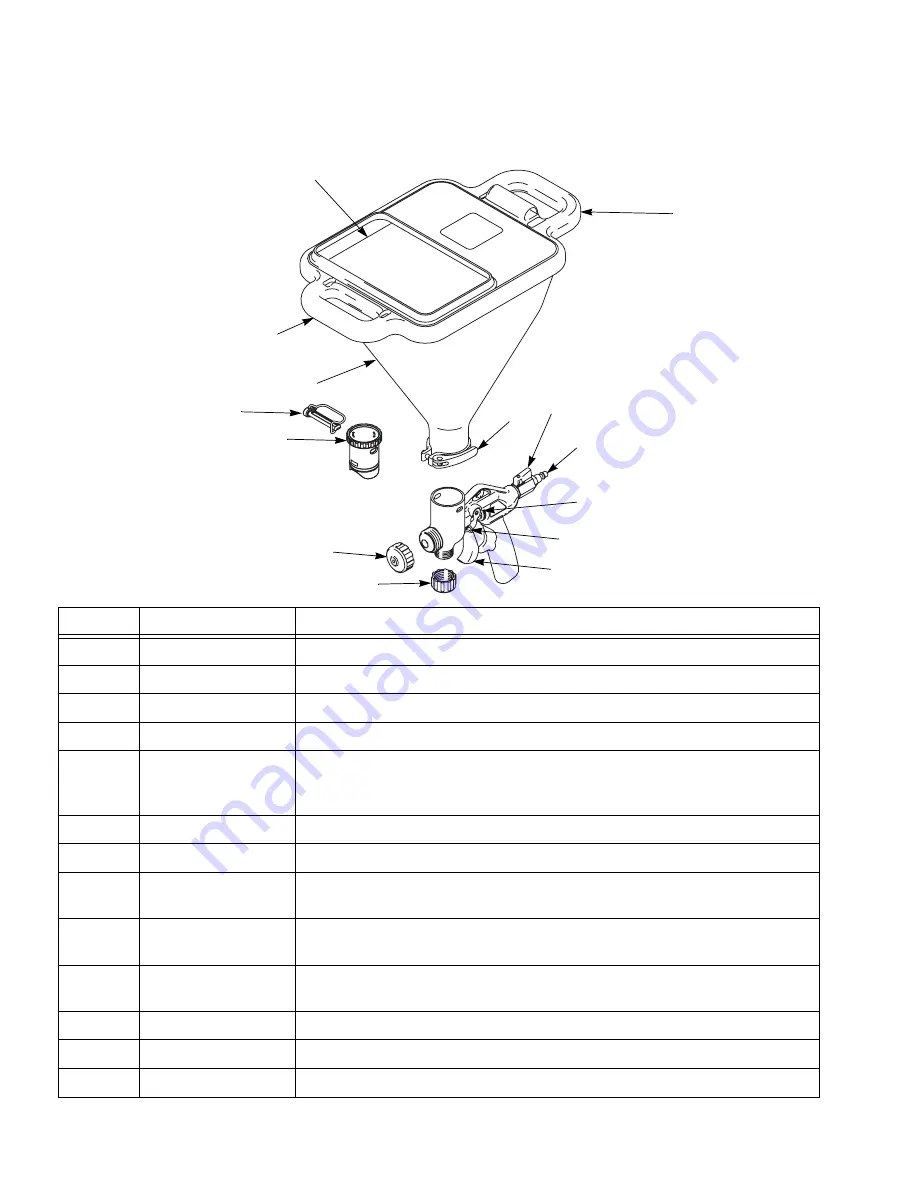

Component Identification

4

309584H

Component Identification

D

C

B

M

A

K

G

E

F

F

H

J

N

P

ti2441b

Identifier

Component

Description

A

Air Valve

Adjusts air to material mix ratio.

B

Flow Adjustment Nut

Sets needle position.

C

Trigger

Engages material flow.

D

Trigger Lock

Holds trigger open to assist operator during long jobs.

E

Material Fill Opening

Where mixed material is loaded into hopper. For overhead applications and high walls, posi-

tion hopper on gun with material fill opening facing toward nozzle (J) (front) of gun. For all

other applications, material fill opening should face toward the air valve (A) (back) of gun.

F

Handles

Provided for operator comfort and relieve operator fatigue during long jobs.

G

Hopper

Holds material.

H

Gun Plug

Must be in place when material hose is used with texture pump system. To use hopper,

remove plug and install hopper as described on page 5.

J

Nozzle

Different sizes available for use with different applications, See Nozzle Selection chart, page

7.

K

Hose Plug

Must be installed when hopper is used. This feature is not utilized in this application. See

Graco RTX manual for installation and operating instructions for this feature.

M

Air Fitting

Quick Disconnect used to attach air hose to gun.

N

Clamp

Secures hopper on gun.

P

Gun Plug Clip

Secures gun plug to gun.

Summary of Contents for 245924 A Series

Page 11: ...Notes 309584H 11 Notes...