Basic Operation

309584H

5

Basic Operation

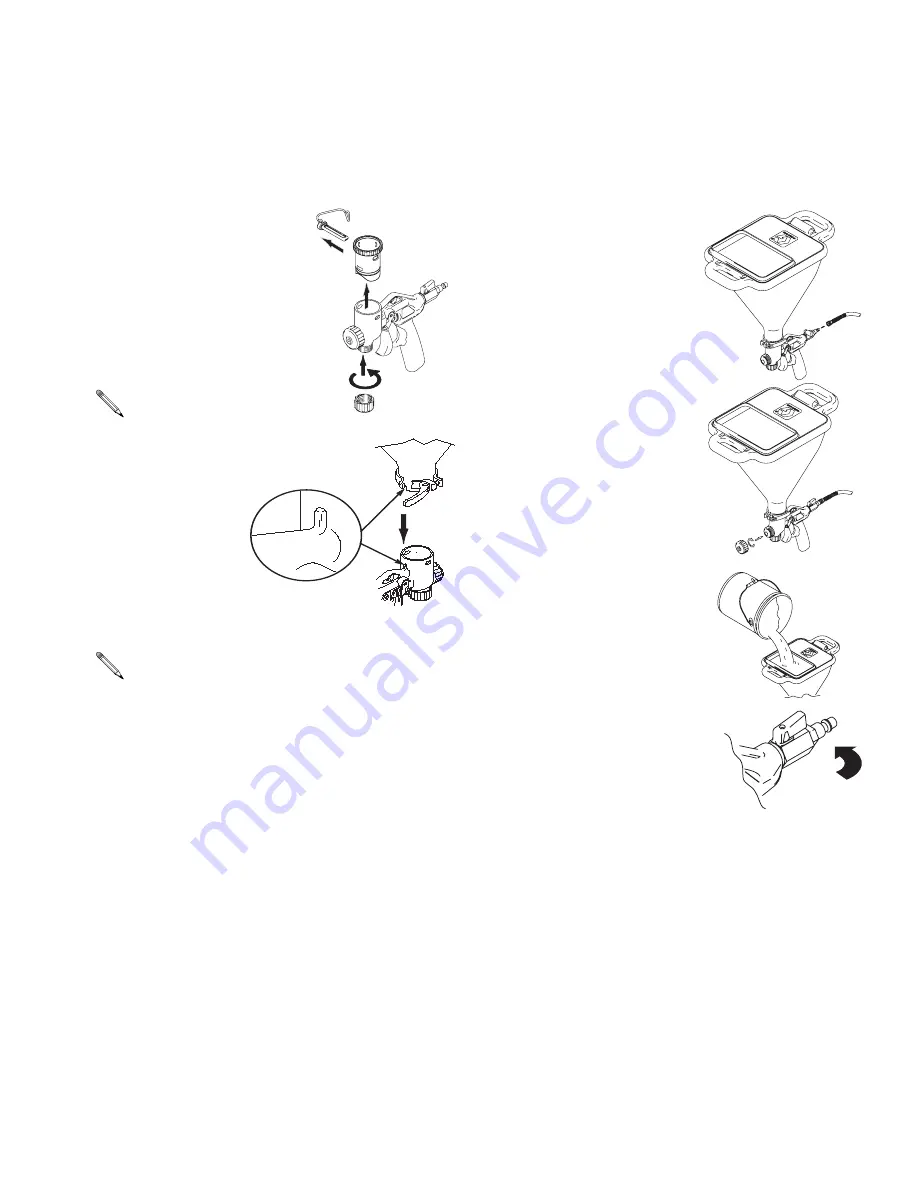

Hopper Installation

1.

The Hose Plug must be

securely fastened to bot-

tom of gun when using the

Hopper. Gun Plug must be

removed from top of gun.

.

2.

Align notched

opening in base

of hopper to

raised notch on

hopper port of

gun body.

3.

Push hopper down, over hopper port as far as it will

go.

4.

Fasten clamp.

5.

Connect air hose to gun.

6.

Install spray nozzle, page

7.

7.

Fill hopper with texture

mix.

8.

Open air valve.

9.

Turn compressor ON.

Close air valve. Adjust air pressure starting at 30-40

psi.

It is easier to remove plug if you first trigger gun.

For overhead applications and high walls, position

the hopper on the gun with the material fill open-

ing facing toward the nozzle (front) of the gun. For

all other applications, material fill opening should

face the air valve (back) of the gun.

ti2699b

ti2644a

ti2449

ti2621a

ti2476

ti2448a

Summary of Contents for 245924 A Series

Page 11: ...Notes 309584H 11 Notes...